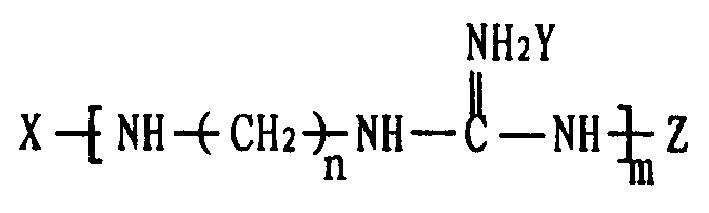

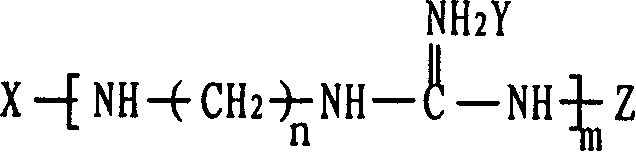

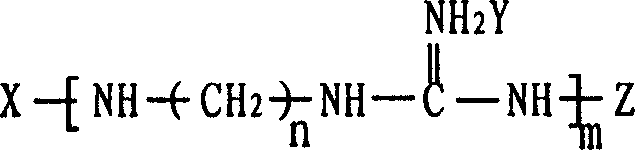

Polyamine guanidine salt copolymer and its uses in antibiotic polyester and polyamide materials

A guanidine salt polymer and polyamine technology, which is applied to polyamine and guanidine salt polymer and its application in antibacterial polyester and polyamide materials, can solve the problem of poor compatibility with polymer materials and limit antibacterial modification. Solve the problems of agent application, poor heat resistance, etc., to achieve the effects of excellent compatibility, overcoming easy migration and poor durability, and excellent processing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Take 172g of 1,10-decanediamine and 200g of guanidine carbonate, put them into a 500ml three-necked bottle, under the protection of nitrogen, stir and raise the temperature to 110°C, react for 1 hour, then raise the temperature to 185°C for 8 hours, then add 8.6 g pyromellitic anhydride, the reaction was terminated after 40 minutes.

[0056] Its number-average molecular weight is 8,600, and its thermal decomposition temperature is 370°C. There are characteristic absorption peaks of guanidinium, amine, amide, acid anhydride and other groups in its infrared spectrum.

Embodiment 2

[0058] Take 122g of 1,6-hexamethylenediamine and 98g of guanidine hydrochloride, add them into a 250ml three-necked bottle, under the protection of nitrogen, stir and raise the temperature to 150°C, react for 5 hours, then raise the temperature to 220°C for 8 hours, then add 1.3 g hexamethylene-1,6-diisocyanate, and the reaction was terminated after 100 minutes.

[0059] Its number-average molecular weight is 26,600, and its thermal decomposition temperature is 366°C. There are characteristic absorption peaks of guanidine, amine, amide, isocyanate and other groups in its infrared spectrum.

Embodiment 3

[0061] Take 85g of hexamethylenetetramine and 280g of guanidine nitrate, add them into a 500ml three-necked bottle, under the protection of nitrogen, stir and raise the temperature to 100°C, react for 2 hours, then raise the temperature to 160°C for 1 hour, then add 36.2g Ethylene glycol bisglycidyl ether, the reaction was terminated after 20 minutes.

[0062] Its number-average molecular weight is 3000, and its thermal decomposition temperature is 365°C. There are characteristic absorption peaks of guanidinium, amine, epoxy and other groups in its infrared spectrum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com