Self-cleaning, antibacterial and anti-fog film

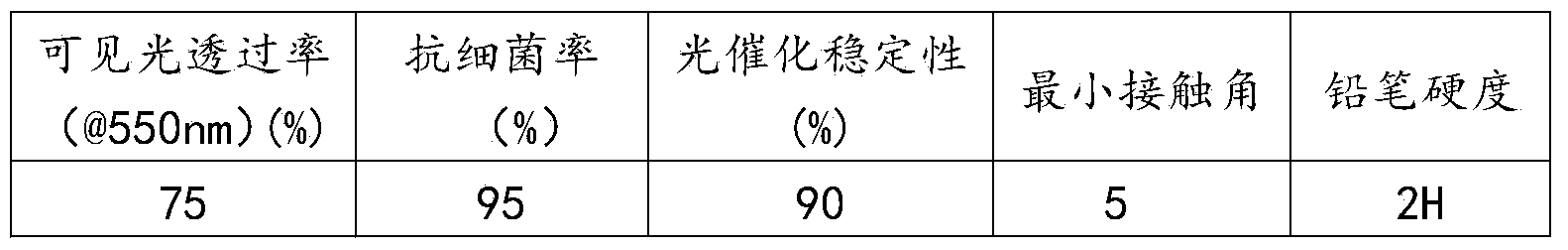

A self-cleaning, thin-film technology, applied in the field of organic polymer and nano-photocatalytic particle composite films, can solve the problems of insufficient photocatalytic stability, low solar energy utilization, and high equipment requirements, and achieve high self-cleaning, antibacterial, and anti-fog functions. , High visible light transmittance, simple and easy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

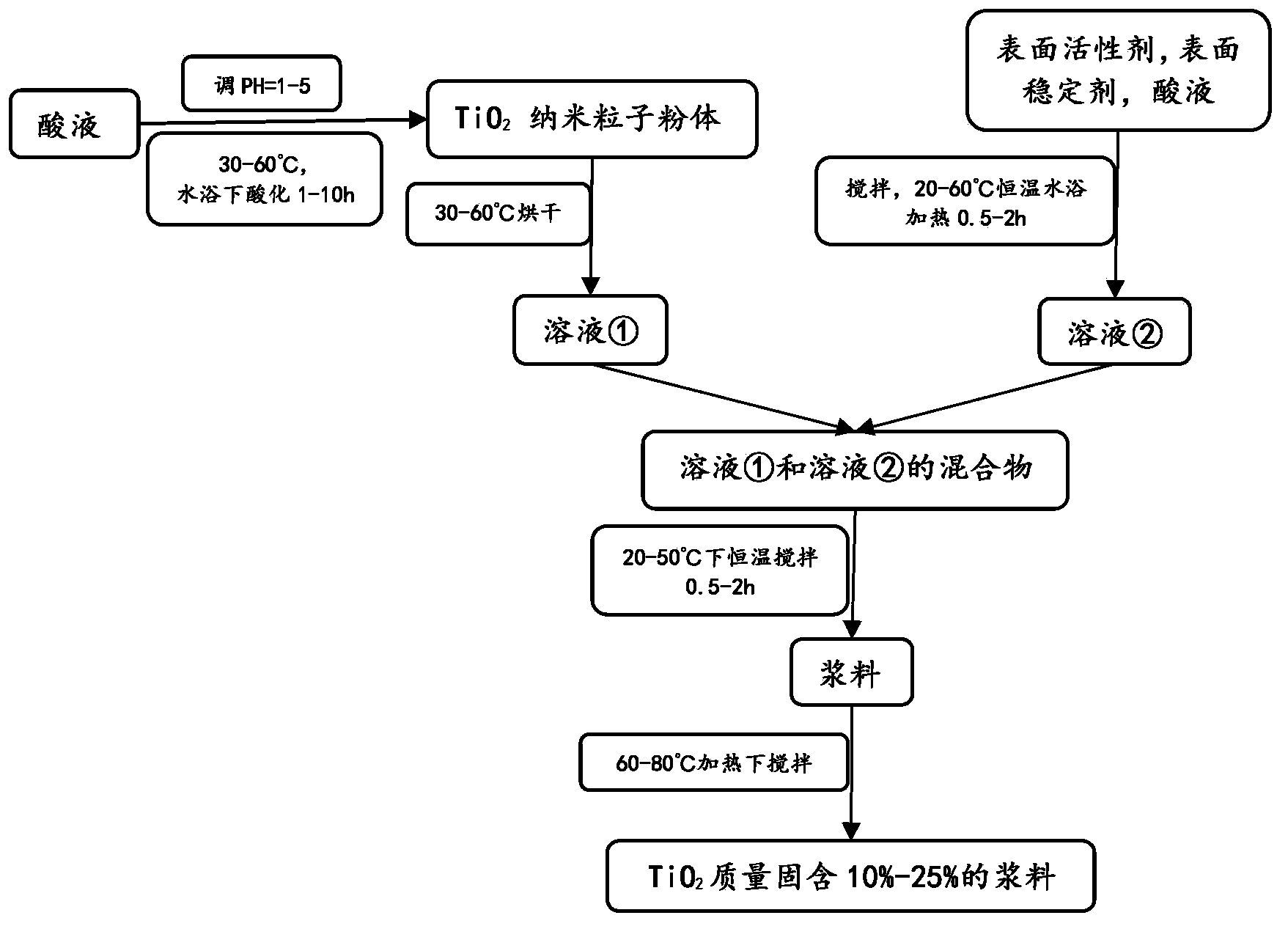

[0039] Anatase Nano Ti0 2 The preparation method can refer to the patent CN03119113.4, mix a certain amount of inorganic titanium compound aqueous solution and lye under stirring, the pH of the mixed solution is 1.5-4, and obtain metatitanic acid seeds; then add a certain amount of inorganic titanium solution to Solution I is formed in the prepared seed crystals; then the solution I is heated to 50-140°C and boiled to obtain a white precipitate, which is filtered and washed to obtain a white filter cake; the white filter cake is dried at room temperature to obtain a white powder, that is, a certain particle size Anatase Nano Ti0 2 Powder.

[0040] Anatase Ti0 2 and rutile Ti0 2 The preparation method of the mixture can refer to the patent CN101643242A, dissolving the special titanium metal complex precursor in a special organic solvent to form a solution II, adding hydrogen peroxide to the solution II, then boiling the reaction in a water bath, heating and drying after the ...

Embodiment 1

[0054] (1) Preparation of TiO 2 Nano particle slurry, concrete steps are as follows: first press above-mentioned anatase type nano Ti0 2 The preparation method prepares the anatase type nanometer Ti0 of particle size 30nm 2 particle powder,

[0055] ①Acidification treatment: the anatase nano-Ti0 2 The particle powder is added to acetic acid with a mass concentration of 68%, and the pH of the mixed solution is controlled to be 1; it is kept in a water bath at 60°C for 1 hour for acidification treatment, and the acidified TiO 2 Dry in an oven at 30°C for subsequent use;

[0056] ② Preparation of solution: first add acetylacetone solvent to the container, then add methyl cellulose, and finally add acetic acid with a mass concentration of 68%, wherein the mass ratio of acetylacetone solvent, methyl cellulose, and acid solution is 5:10:0.007 , stirred on a stirrer, heated in a constant temperature water bath at 20°C for 0.5 hours during the period, and prepared a solution for ...

Embodiment 2

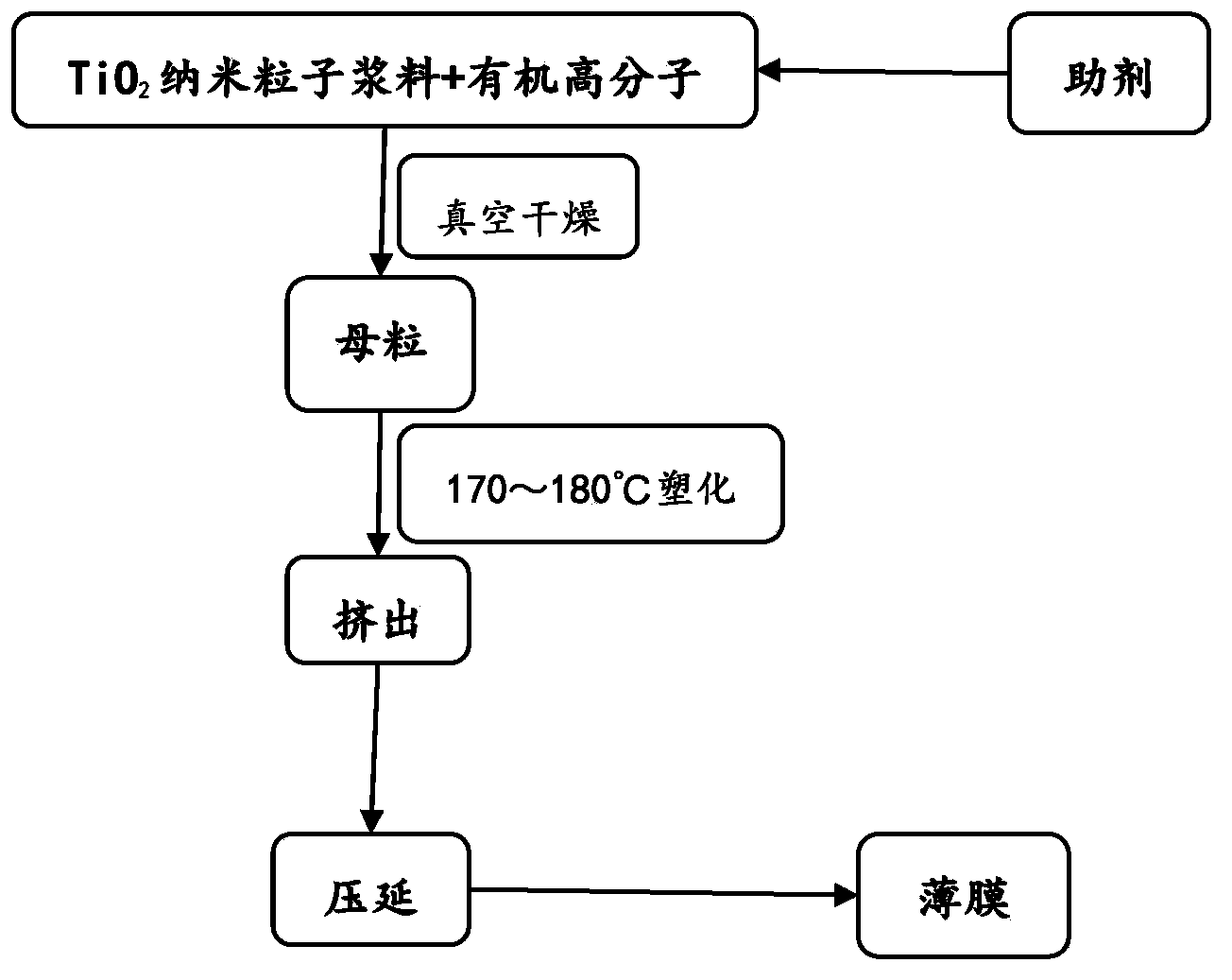

[0064] Embodiment 2: with embodiment 1, the difference is that in step (2), by weight percentage, the above-mentioned prepared 0.5 anatase nano-TiO 2 Particle slurry, add 76.05 of polycarbonate, 1.51 of 3-glycidyloxypropyldimethoxysilane, 19.01 of 2-(2'hydroxyl-5' Methylphenyl) benzotriazole, 0.91 of 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl) butane and 0.91 of triphenyl phosphite are fully stirred, Mix and remove volatile small molecule solvents in a vacuum oven to obtain masterbatches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com