Preparation method of dopamine modified nano-silver textile fabric

A technology of textile fabrics and nano-silver, applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., to achieve the effects of high production efficiency, high fastness, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of described nano-silver textile fabric is characterized in that, first textile fabric is pretreated with dopamine, and then AgNO 3 Add it into distilled water, and add dopamine pre-treated textile fabric, then microwave for a certain period of time, take it out and turn it every 1 minute, and finally wash and dry the textile fabric.

[0031] The preparation method of described nano-silver textile fabric, is characterized in that, described textile fabric is at least one in natural fiber fabric or chemically synthesized textile fabric; Described modifier is dopamine; Described preparation method adopts microwave method .

[0032] The preparation method of the nano-silver textile fabric is characterized in that the dopamine pretreatment method is: dissolving dopamine in deionized water, adding tris to the solution to adjust the pH to 7-10, dopamine and textile The mass ratio of the fabric is 0.1~10, the cloth sample is put into the solution and so...

Embodiment 1

[0042] The bamboo pulp fiber fabric with a size of 5cm×5cm was ultrasonically cleaned with acetone and ethanol for 30min respectively, and the fabric was taken out and dried naturally in a ventilated place; a piece of bamboo pulp fiber fabric cleaned with ethanol and acetone was impregnated with trimethylolamino methane to adjust the pH to 8.5 in a dopamine solution with a concentration of 3 g / l, let it stand for 24 hours, take it out, wash it with deionized water, and then dry it at 80°C. Put the bamboo pulp fiber fabric pretreated by dopamine in a silver nitrate solution with a concentration of 2g / l, heat it in a microwave for 3 minutes, and turn it once every minute to ensure that the cloth surface is evenly coated with nano-silver. Remove to dry.

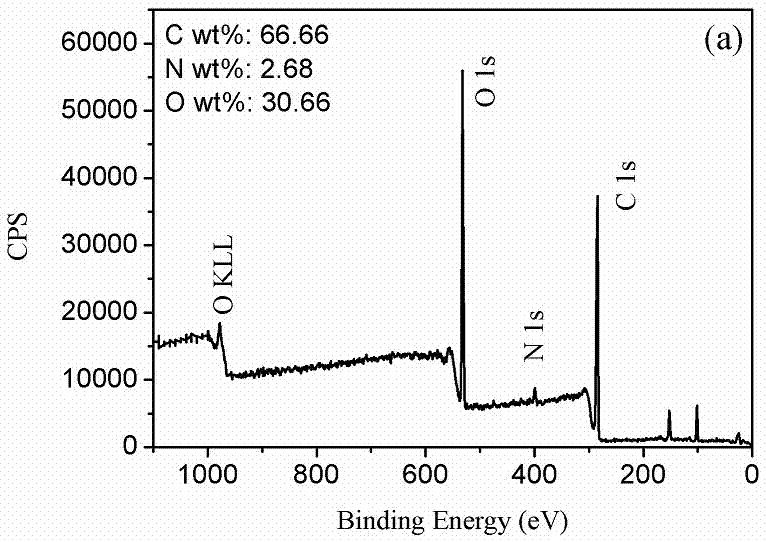

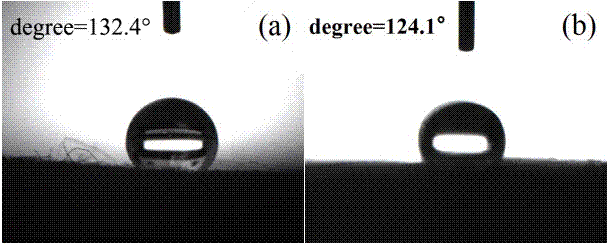

[0043] The microstructure and macroscopic properties of the obtained nano-silver bamboo pulp fiber fabric are as follows.

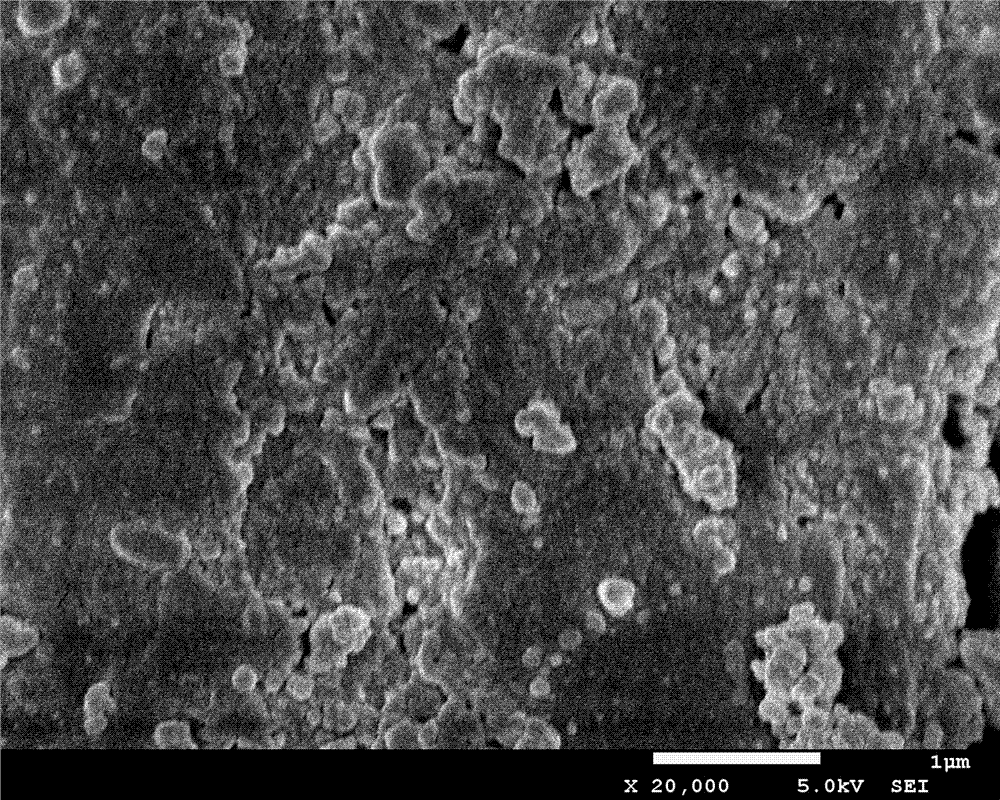

[0044] 1. Morphology of nano-silver particles:

[0045] figure 1 A scanning electron microscope (SEM)...

Embodiment 2

[0053] The wool fabric with a size of 5cm×5cm was ultrasonically cleaned with acetone and ethanol for 30min respectively, and the fabric was taken out and dried naturally in a ventilated place; a piece of bamboo pulp fiber fabric cleaned with ethanol and acetone was soaked in a tris hydroxymethyl aminomethane conditioned pH to 8.5 in a dopamine solution with a concentration of 3 g / l, take it out after standing for 12 hours, wash with deionized water, and then dry at 80°C. Place the bamboo pulp fiber fabric pretreated by dopamine in a silver nitrate solution with a concentration of 2g / l, heat it in a microwave for 3 minutes, and turn it once every minute to ensure that the fabric surface is evenly coated with nano-silver. Remove to dry.

[0054] Morphological analysis of silver nanoparticles:

[0055] Figure 5 A scanning electron microscope (SEM) photograph of the nanosilver wool fabric. Depend on Figure 5 It can be seen that the nano-silver particles are tightly packed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com