Formwork removal-free reinforced concrete column construction device

A technology for reinforced concrete columns and construction devices, applied in the direction of formwork/formwork/work frame, column, pier column, etc., can solve the problem of uneven thickness of concrete protective layer, increased steel and wood consumption, need to reassemble or Customized and other issues to achieve the effect of ensuring sturdiness and aesthetics, reducing consumption, saving resources and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

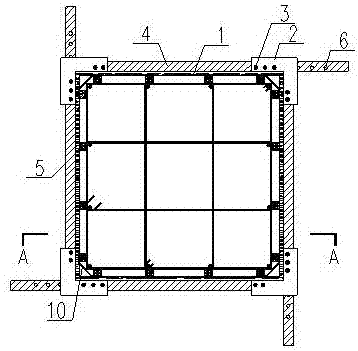

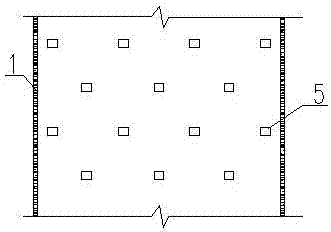

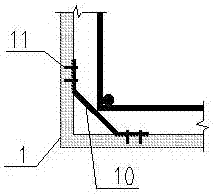

[0020] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment includes a column-shaped reinforcement cage, and the outer side of the reinforcement cage is provided with a cement fiberboard 1 connected to the surface of the closed reinforcement cage, and the inner surface of the cement fiberboard 1 is provided with rectangular bumps 5 distributed in a quincunx shape; two pairs of cement fiberboards are connected The outer connection angle of 1 is provided with corner angle steels 2 at intervals in the vertical direction, and connecting pieces 4 are pierced between two adjacent corner angle steels 2 on the same horizontal plane; the inner sides of the two sides of the corner angle steels 2 Partial grooves 7 and through grooves 8 are provided respectively, the connecting piece 4 is pierced on two adjacent corner angle steels 2, and one end of the connecting piece 4 is located in the local groove 7, and the other end passes through the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com