Lens assembled fixture and assembling system possessing same and assembling method

A technology for assembling fixtures and assembling systems, which is applied in the directions of installation, optics, and instruments, and can solve problems such as insufficient pressure of optical components, defective products, and reduced product assembly yields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further illustrate the present invention, a preferred embodiment is given and described in detail below with accompanying drawings.

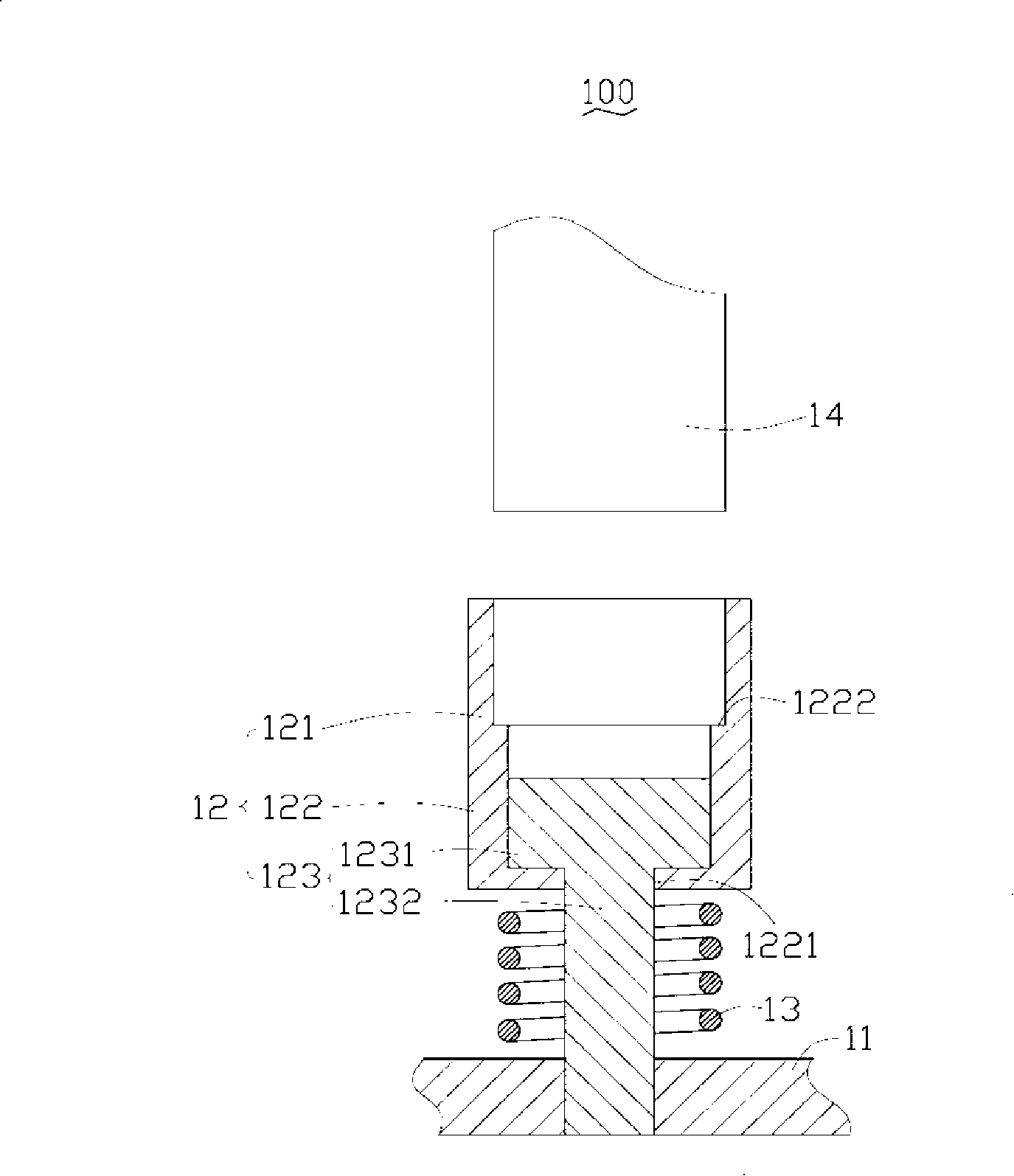

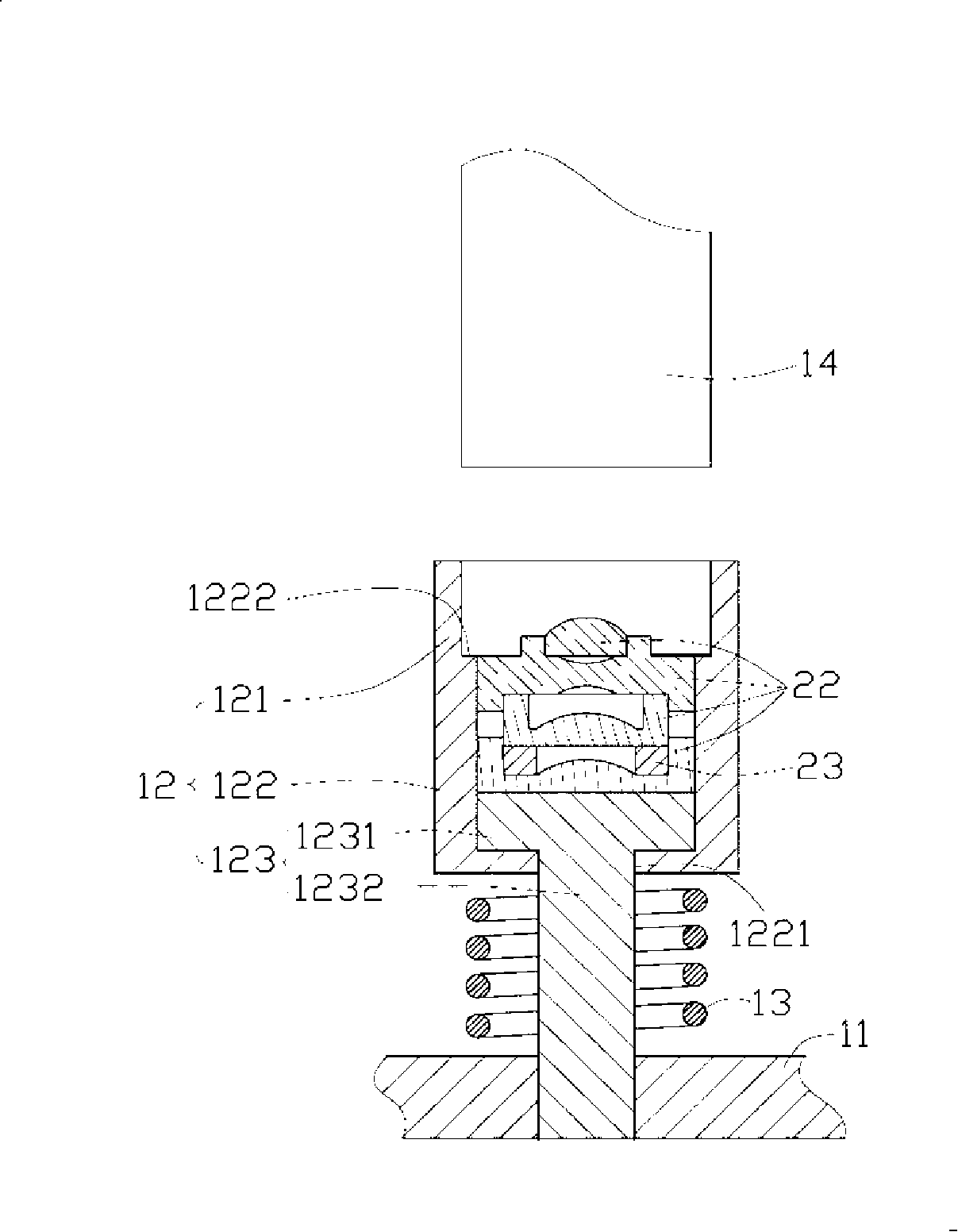

[0022] see figure 1 and figure 2 , the lens assembly system 100 of the embodiment of the present invention is used to assemble the lens module 20, including a base 11, a lens assembly jig 12 arranged on the base 11, and a lens assembly jig 12 sleeved on the lens assembly jig 12 The elastic member 13 and a push rod 14 on it.

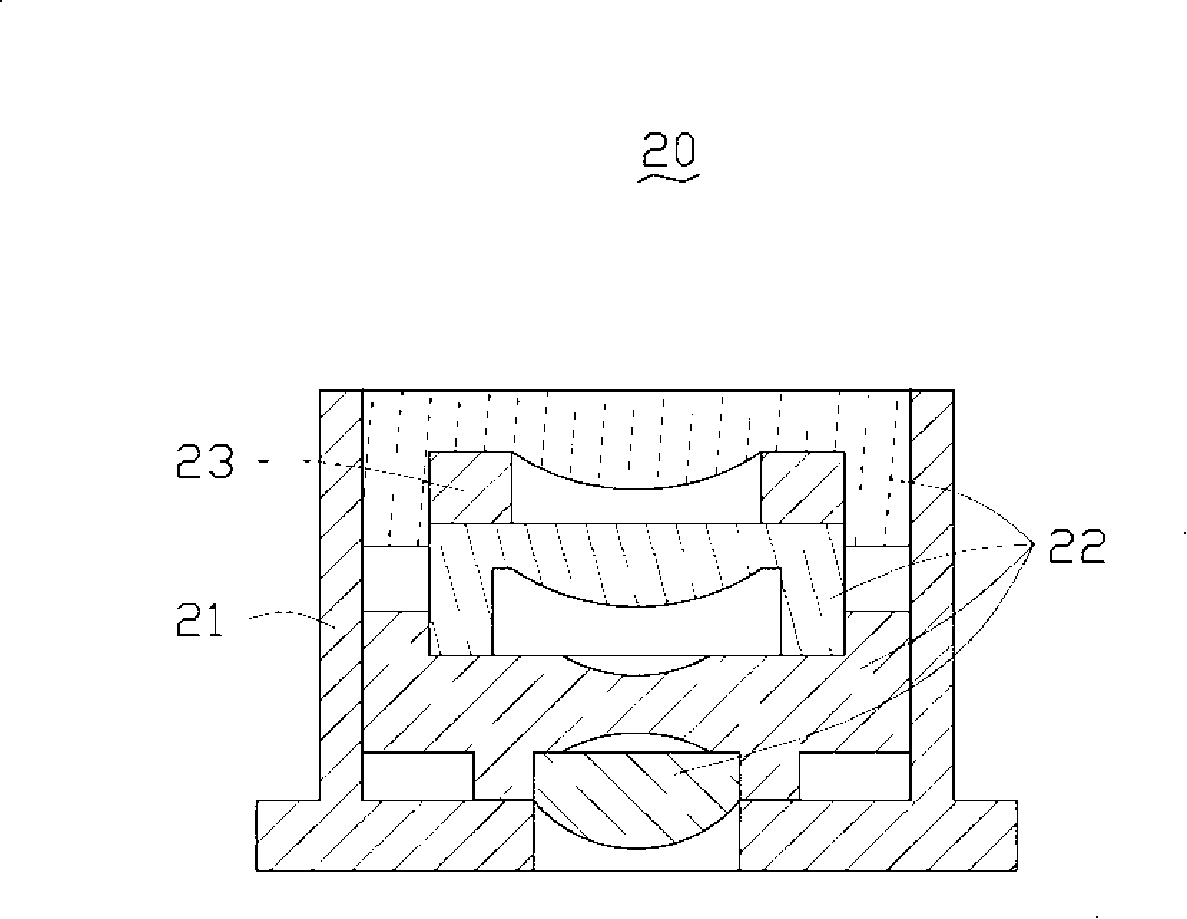

[0023] The lens module 20 includes a lens barrel 21 and a lens group 22. In this embodiment, the optical element of the lens module 20 is a lens group 22, which includes four lenses, and its shape and size are set according to requirements. Certainly.

[0024] The lens module 20 includes a spacer ring 23 for adjusting the distance between the lenses to adjust the focal length of the lens module.

[0025] The base 11 is fixed on a machine platform (not shown), and can be moved as required.

[0026] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com