Optical film coating device

An optical coating and flange technology, applied in optics, optical components, sputtering coating, etc., can solve the problems affecting the quality of the coating, and achieve the effect of stable connection and not easy to tilt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below with reference to the accompanying drawings.

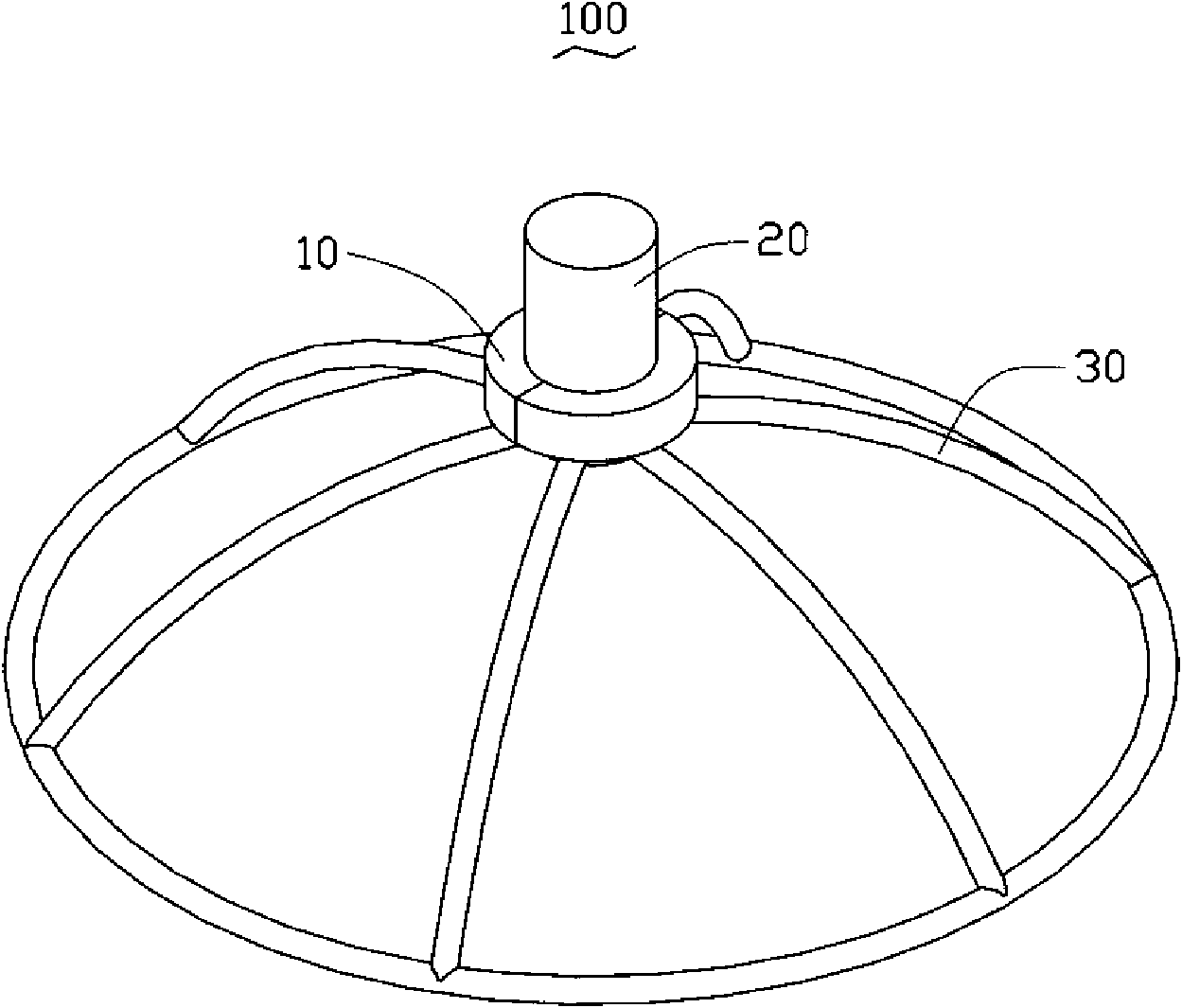

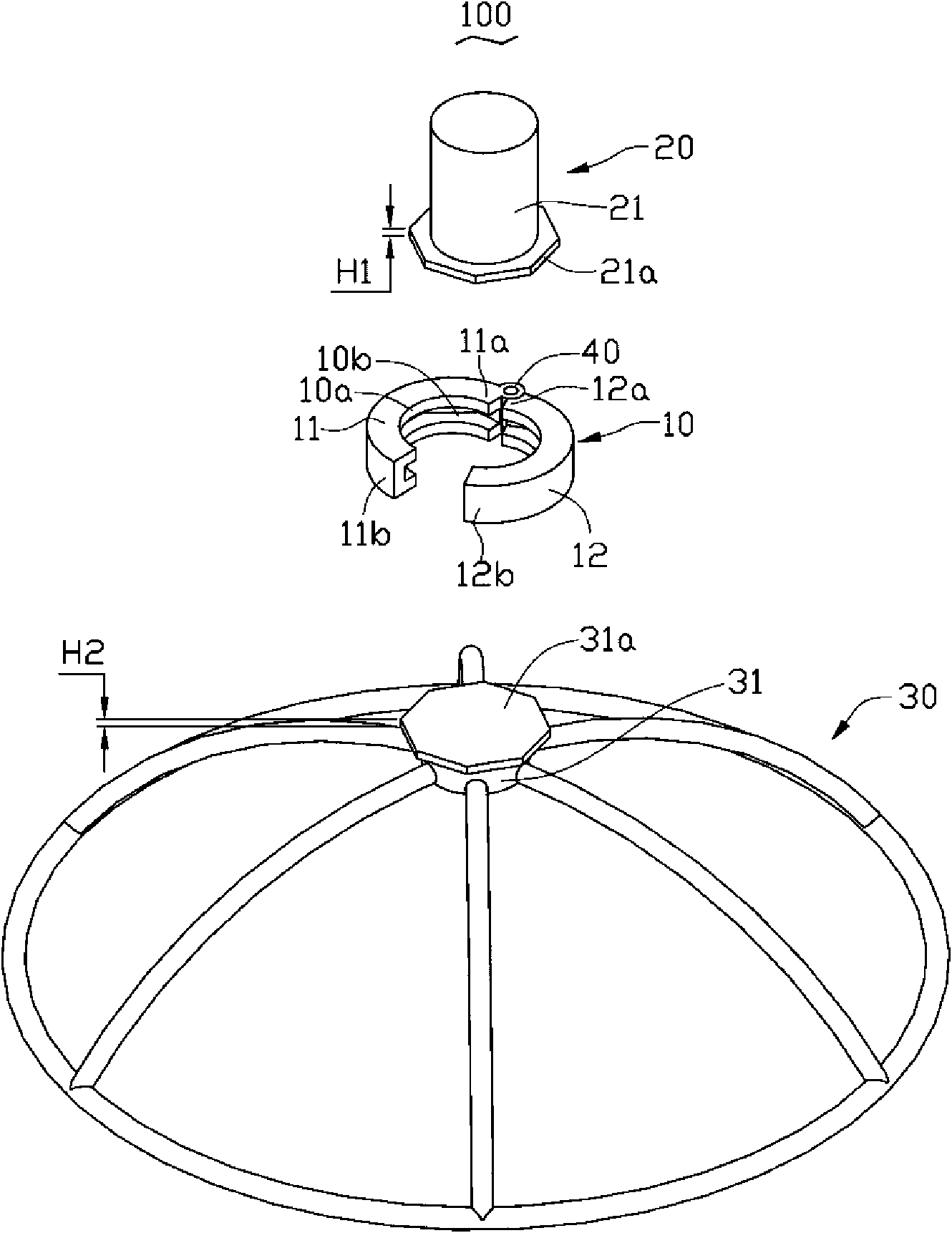

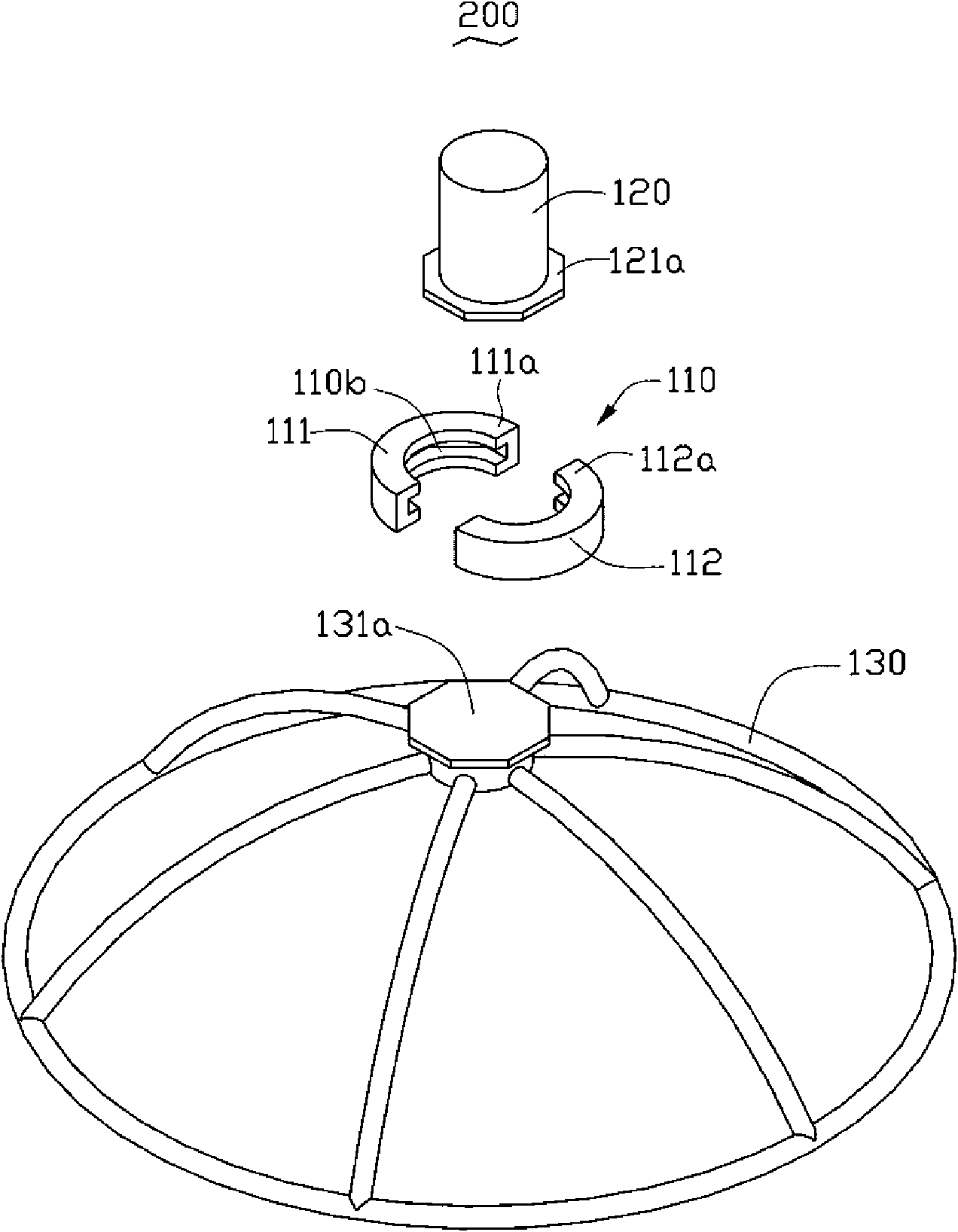

[0014] see figure 1 , the first embodiment of the present invention provides an optical coating device 100 . The optical coating device 100 includes a snap ring 10 , a rotating shaft 20 and a substrate carrier 30 .

[0015] see figure 2 , the inner annular surface 10a of the snap ring 10 has a groove 10b. The groove 10b of the snap ring 10 may have geometric shapes such as a circle, an ellipse or a regular polygon. In this embodiment, the snap ring 10 is circular. In order to facilitate the transmission of torque and the uniform force, the groove 10b adopts a regular octagon. The snap ring 10 includes a first half ring 11 and a second half ring 12 . The first half ring 11 has a first end 11a and a second end 11b. The second half ring 12 has a third end 12a and a fourth end 12b. The first end 11a and the third end 12a are hinged. In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com