Automatic hand bag feeding machine

A handbag and bag supply technology, which is applied in the field of automatic handbag supply machine, can solve the problems that affect the work efficiency, the labor intensity of equipment operators, the automatic packaging unit cannot realize automatic bag supply, and the handbag is easy to tilt, etc., so as to reduce labor costs. Low labor intensity, convenient and fast bag supply, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

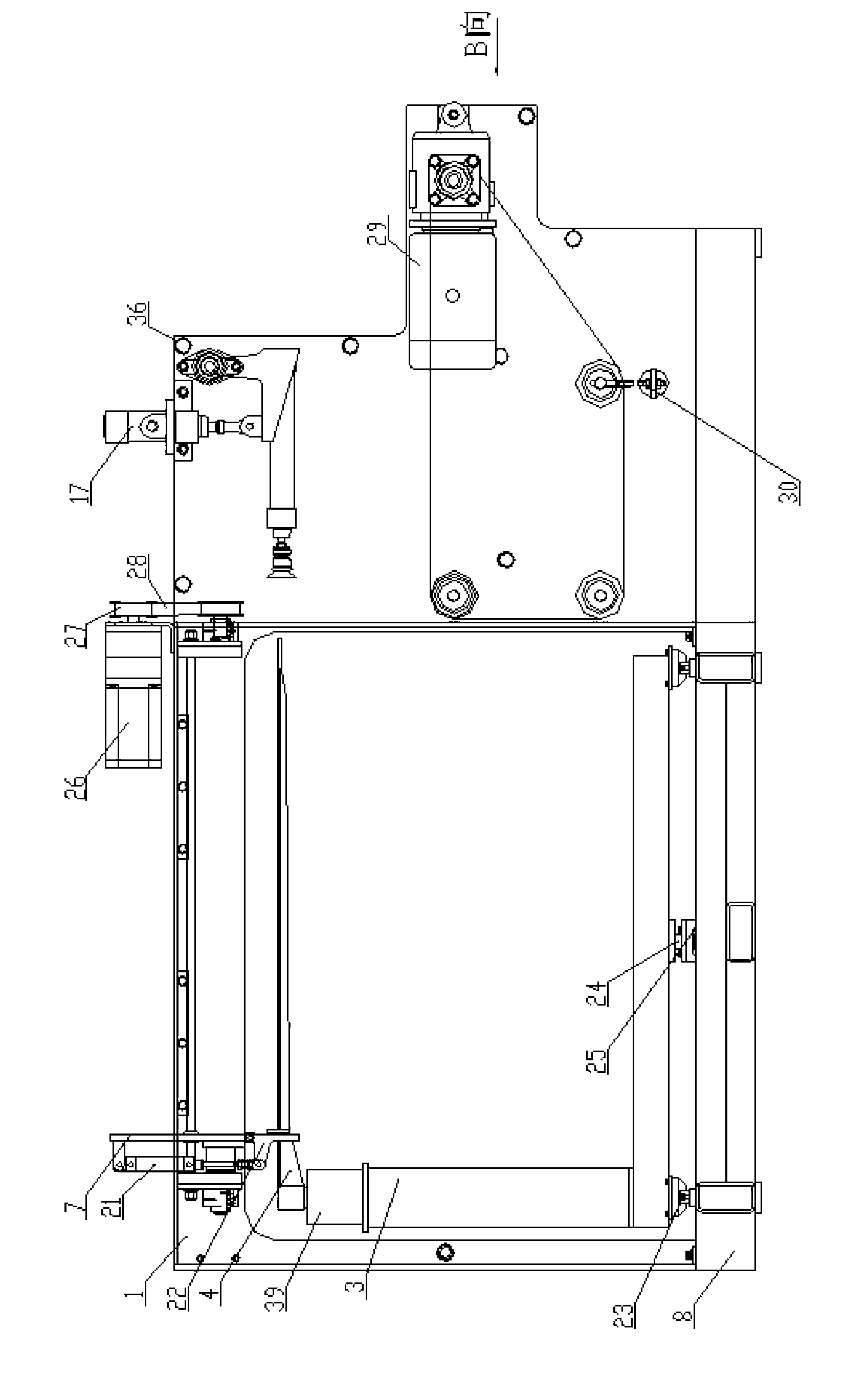

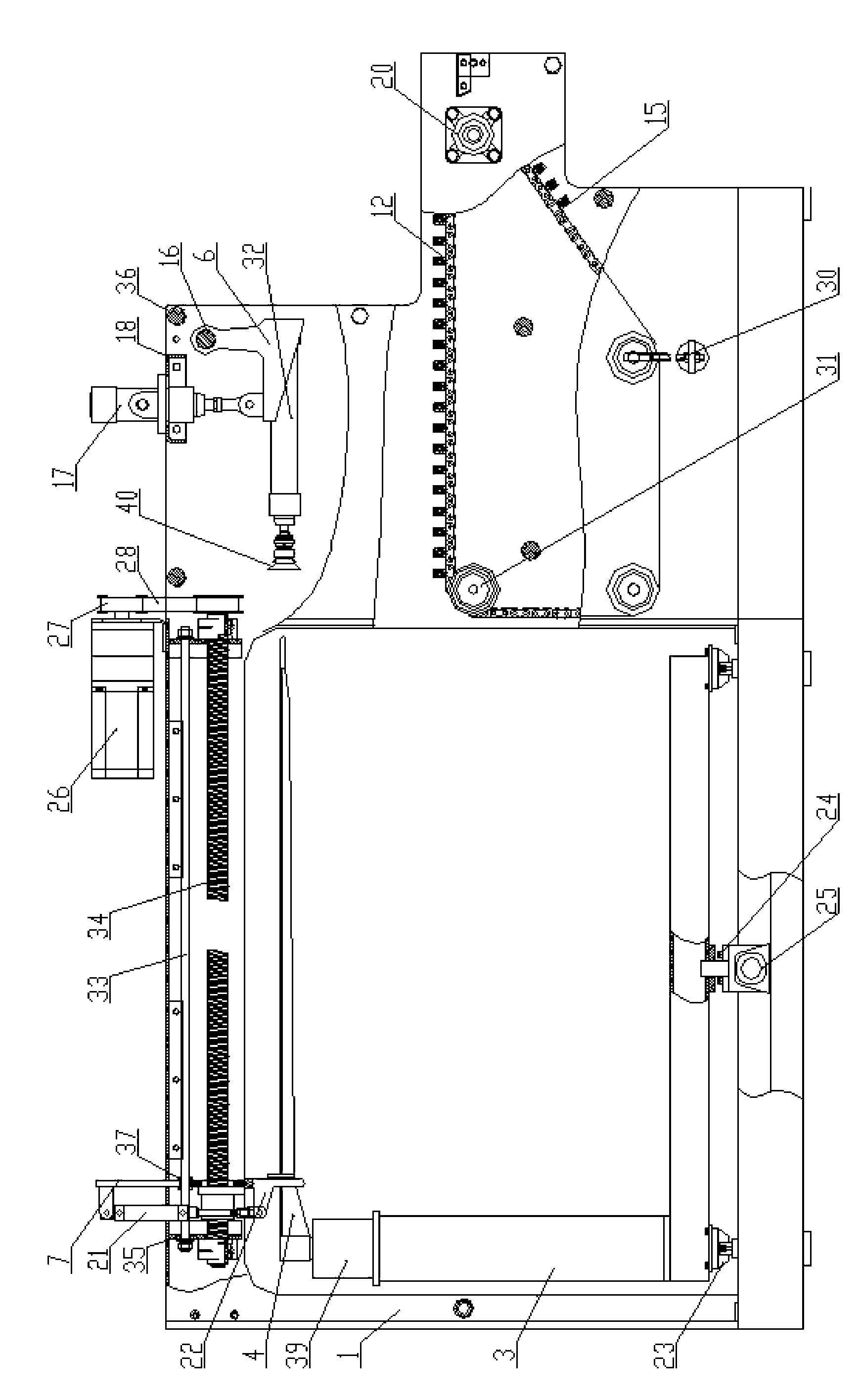

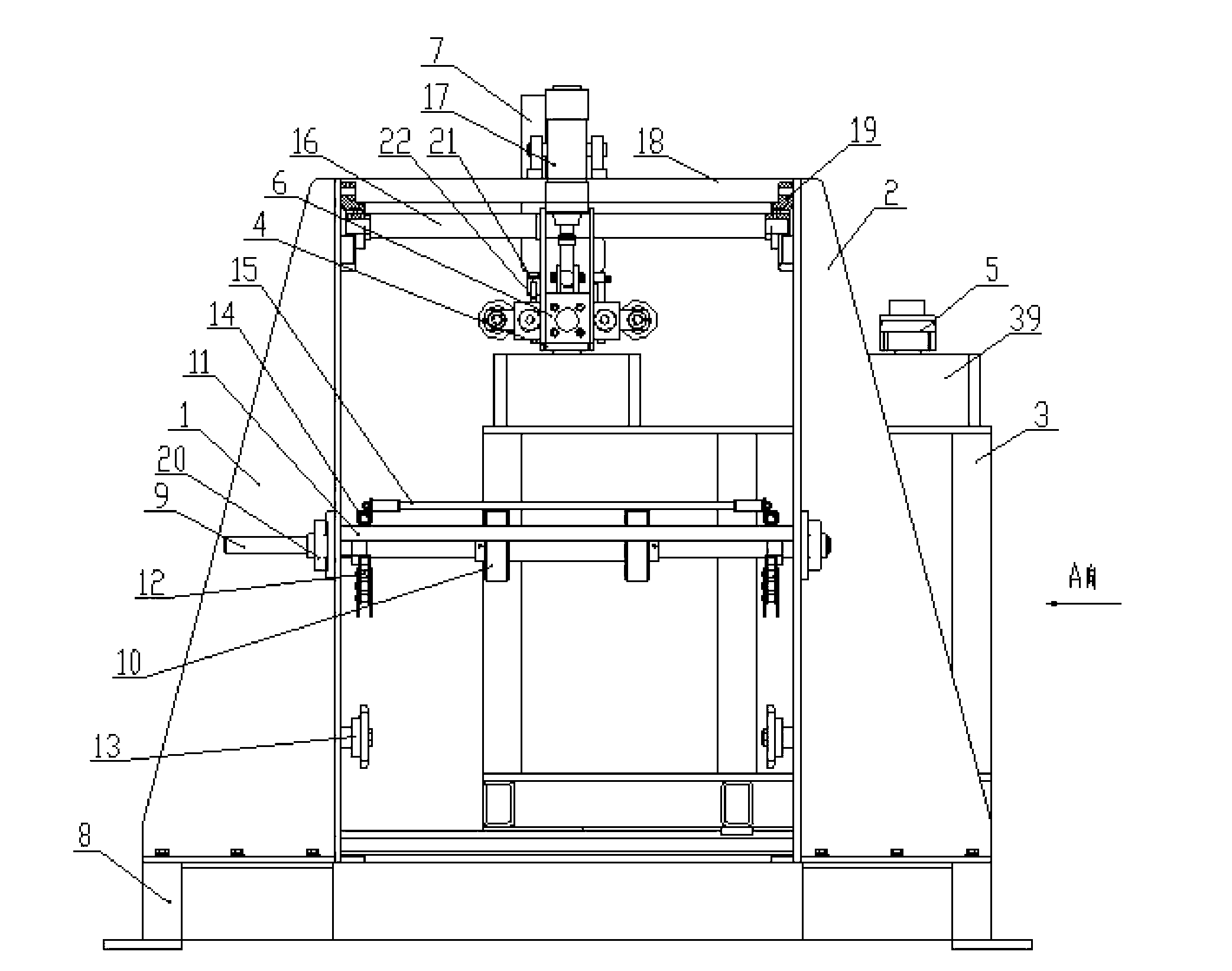

[0021] Referring to the accompanying drawings, an automatic bag feeder for handbags includes a bottom frame 8 on which left and right support frames 1 and 2 are erected, and on the bottom frame 8 between the left and right support frames 1 and 2 There is a mobile frame 3 that can move left and right. One or more bag holders are set up on the mobile frame 3. A bag pushing fork assembly 7 that can push the handbag to run is provided above the bag holder. The bag supply suction cup assembly 6, the bag supply suction cup assembly 6 is installed on the frame, the bag supply suction cup assembly 6 is provided with a cylinder that drives the bag taking suction cup 40 to move horizontally to pick up and rotate the material, and the machine below the bag supply suction cup assembly 6 The shelf is equipped with a circular conveying mechanism, the feeding end of the circulating conveying chain is located directly below the bag-taking suction cup 40, and the discharging end of the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com