Automatic bagging machine

A bagging machine and automatic technology, applied in packaging and other directions, can solve the problems of materials falling out of the packaging bag, the packaging bag is easy to fall off, and the probability of failure increases, so as to achieve a continuous packaging process, simple structure, and simplified structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

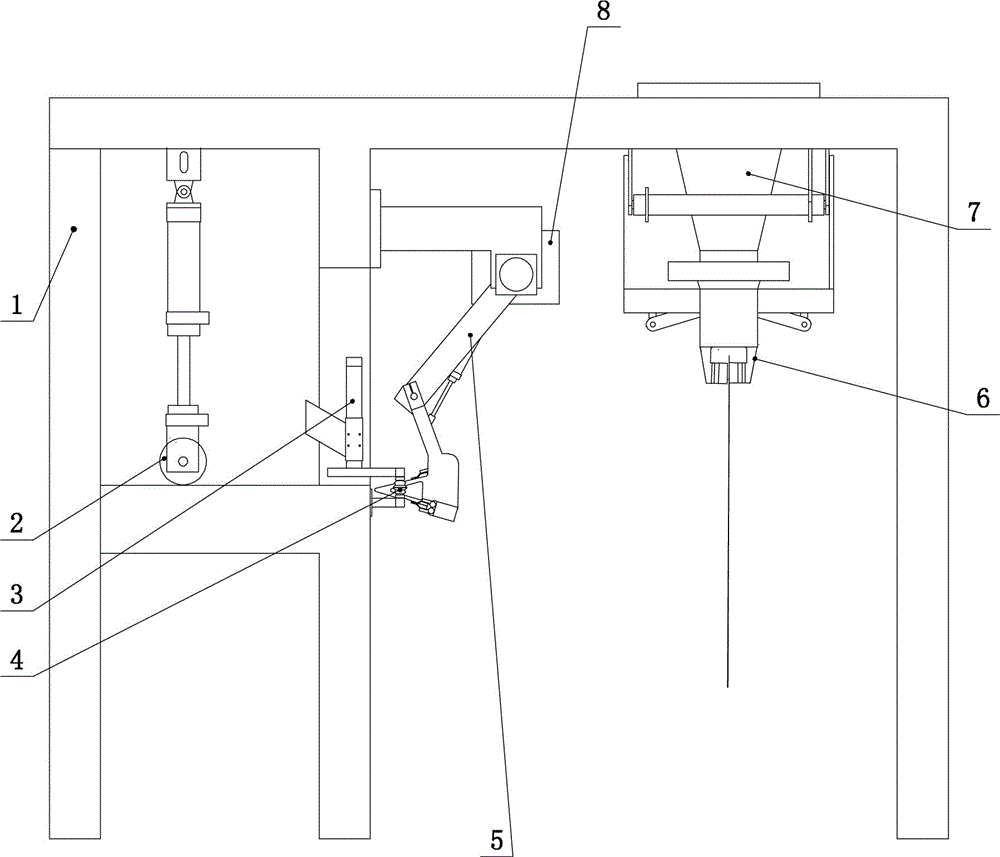

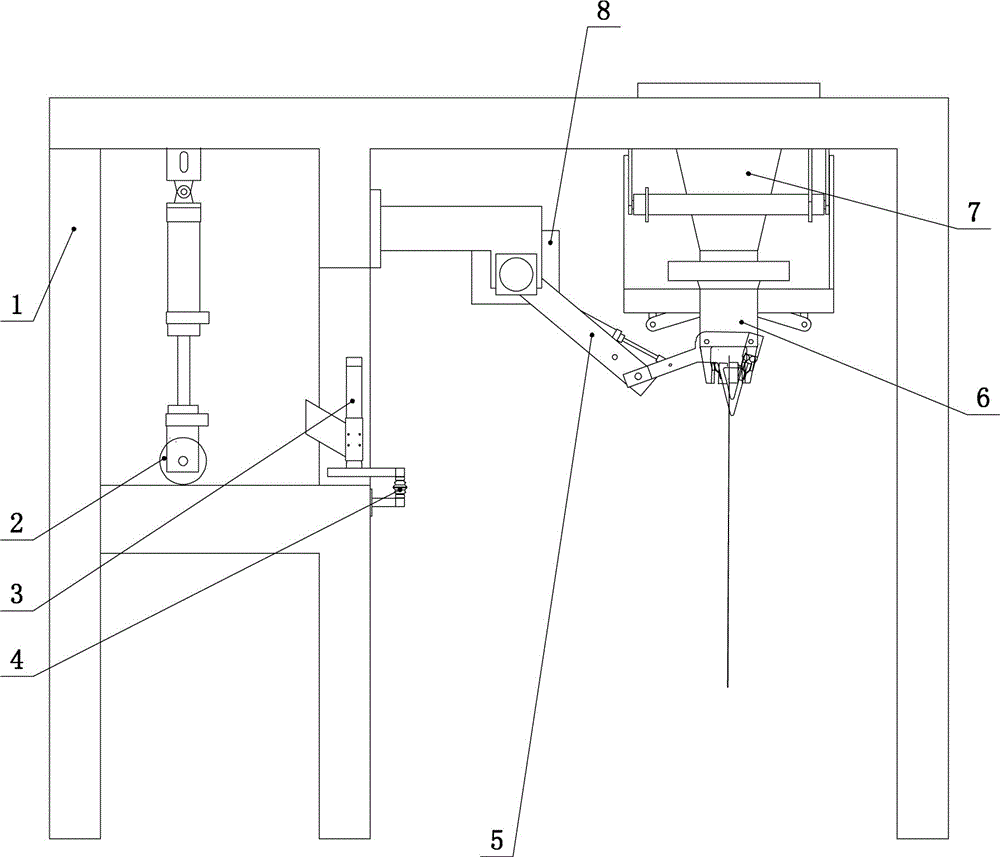

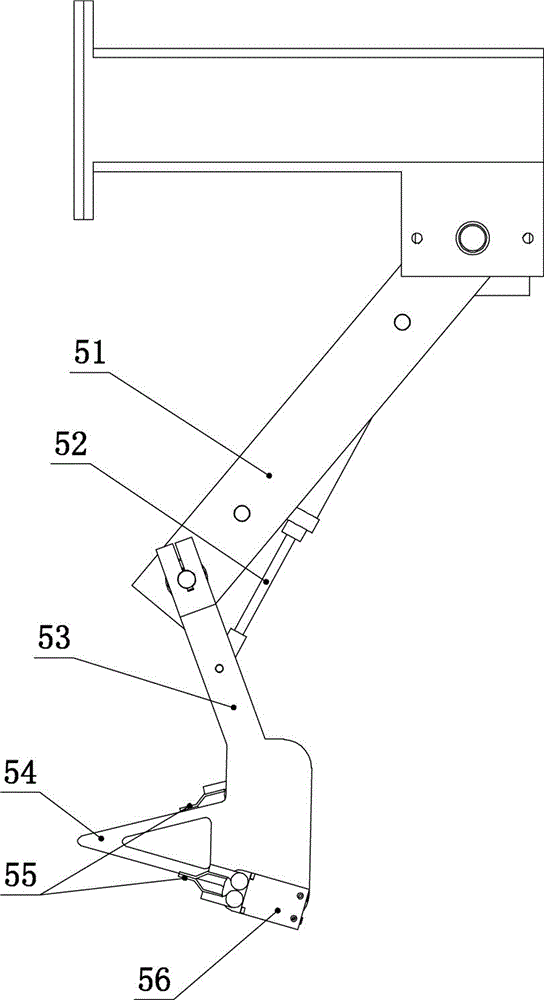

[0027] An automatic bagging machine, such as Figure 1 to Figure 6 As shown, it includes a frame 1, on which a roller 2, a brace cylinder 3 and a brace suction cup 4 are installed, the brace suction cup 4 is connected to the brace cylinder 3 in transmission, the roller 2 is arranged horizontally, and the roller 2 and the brace suction cup Corresponding to 4, a servo motor 8 is also fixedly installed on the frame 1, and the servo motor 8 is connected with a manipulator 5 through transmission. The manipulator 5 includes an upper arm 51, and the upper arm 51 is connected with the servo motor 8 through transmission. A sharp nozzle cylinder 52 is fixedly connected between the upper arm 51 and the lower arm 53, and the other end of the lower arm 53 is fixedly connected with a pocket mouth holding nozzle 54, which corresponds to the support mouth sucker 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com