A kind of transparent electromagnetic shielding film and preparation method thereof

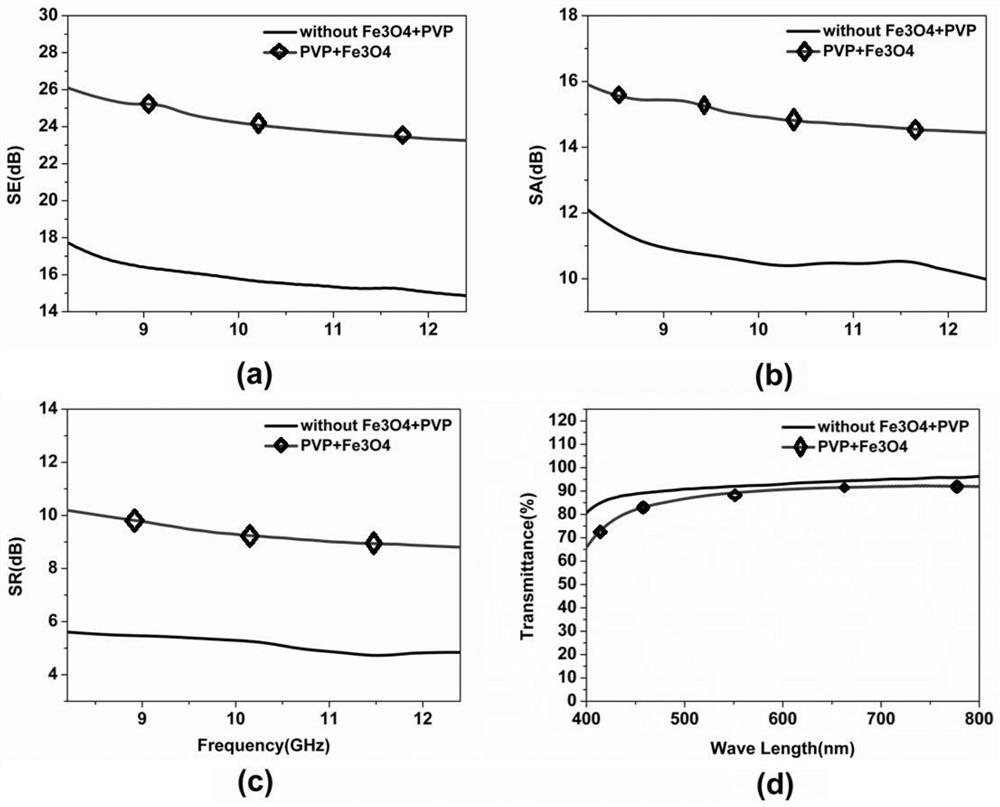

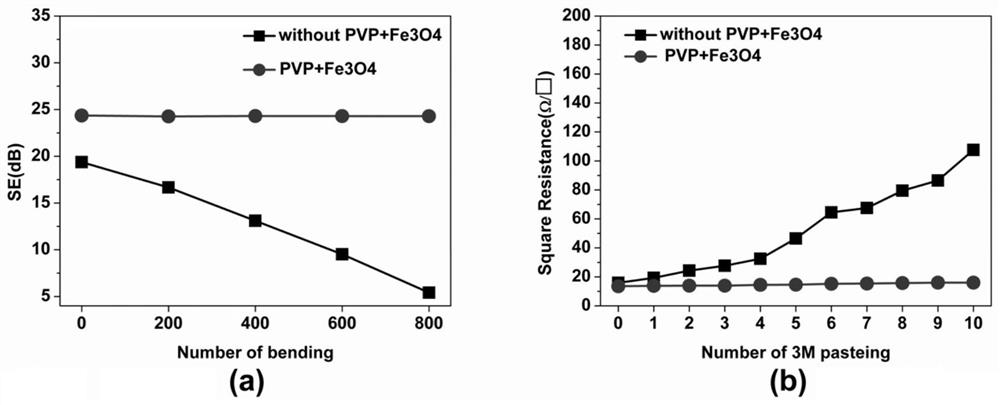

An electromagnetic shielding and film technology, applied in the field of transparent electromagnetic shielding film and its preparation, can solve the problems of reduced electromagnetic wave reflection ability, weak interaction force, poor film connectivity, etc., and achieve the effect of increasing shielding ability and increasing absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Substrate 1 is glass, polyethylene terephthalate (PET) film, polyimide PI film, polyvinyl alcohol PVA film, polystyrene (PS) film or polydimethylsiloxane (PDMS) ) any of the films. A kind of preparation method of transparent electromagnetic shielding film of the present invention comprises the following steps:

[0045] S1, using acetone, ethanol and deionized water to clean the substrate;

[0046] S2, coating the silver nanowire dispersion with a concentration of 0.5-10 mg / ml on the surface of the substrate;

[0047] S3, annealing the substrate prepared in step S2 within a temperature range of 50-100° C. for 0.2-1 hour to make a semi-finished product;

[0048] S4, coating the dispersion composed of iron ferric oxide nanoparticles and polyvinylpyrrolidone on the surface of the semi-finished product prepared in step S3;

[0049] S5, annealing the semi-finished product prepared in step S4 at a temperature range of 50-100° C. for 0.2-1 hour to prepare a transparent elect...

Embodiment 1

[0053] A kind of transparent conductive film prepared by spin-coating method

[0054] Preparation of ferric oxide metal oxide nanoparticles and polyvinylpyrrolidone dispersion:

[0055] First, 100mg of Fe 3 o 4 Nanoparticles were added to 20ml of ethanol, 300mg of polyvinylpyrrolidone was added after sonication at room temperature for 15 minutes, and then the mixture was sonicated at 600kw for 1 hour, and then a stable Fe 3 o 4 Metal oxide nanoparticles and polyvinylpyrrolidone suspension.

[0056] Substrate preparation:

[0057] The glass substrate was sonicated in an acetone-ethanol blend solution with a volume ratio of 1:1 for 5 minutes, then in deionized water for 10 minutes, then taken out and dried with nitrogen, and then treated in a UV-ozone equipment for 10 minutes for use.

[0058] Preparation of transparent conductive film:

[0059] Silver nanowires dispersed in IPA at a concentration of 3.5 mg / ml were dropped onto the substrate, spin-coated at 4000 rpm for 60...

Embodiment 2

[0064] Embodiment 2 A kind of transparent electromagnetic shielding film prepared by ultrasonic spraying method

[0065] Preparation of ferric oxide metal oxide nanoparticles and polyvinylpyrrolidone dispersion: first 50mg of Fe3O4 nanoparticles were added to 20ml of ethanol, and 200mg of polyvinylpyrrolidone was added after ultrasonication at room temperature for 15 minutes, and then the mixture was heated at 600kw Ultrasonic crushing was carried out for 1 hour, and then a stable suspension of iron ferric oxide metal oxide nanoparticles and polyvinylpyrrolidone was obtained.

[0066] Preparation of the substrate: The polyimide (PI) film substrate was sonicated in an acetone-ethanol blend solution with a volume ratio of 1:1 for 5 minutes, then in deionized water for 10 minutes, then taken out and dried with nitrogen, and then Treat in ultraviolet ozone equipment for 10 minutes for standby;

[0067] Preparation of transparent conductive film: adding silver nanowires dispersed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com