Ball-and-socket joint with sensor system and wear measurement method

A sensor device, ball-and-socket joint technology, applied in bearing assembly, transportation and packaging, traction connectors, etc., can solve the problems of high manufacturing overhead, failure threat, and high cost of ball-and-socket joints, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

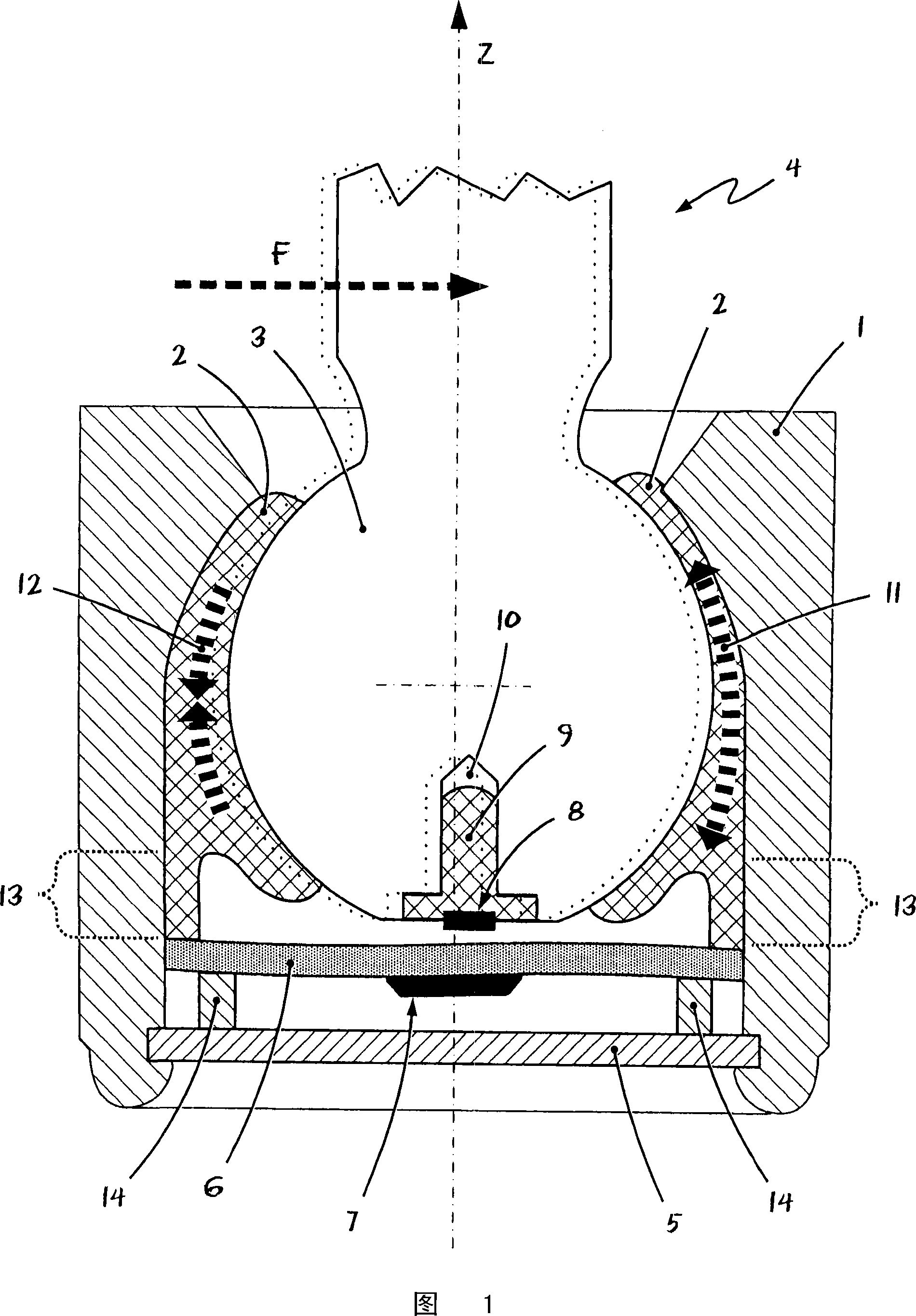

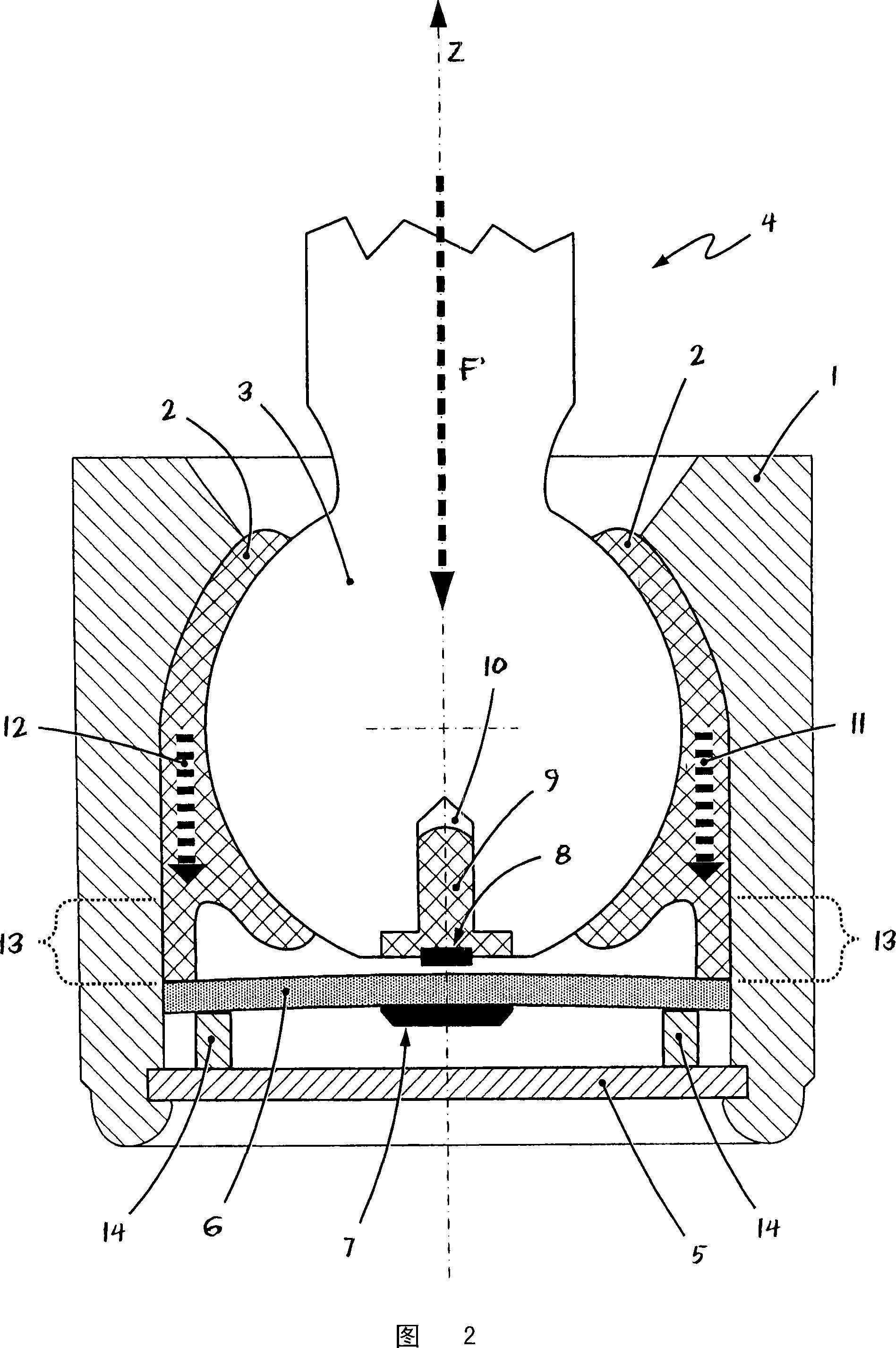

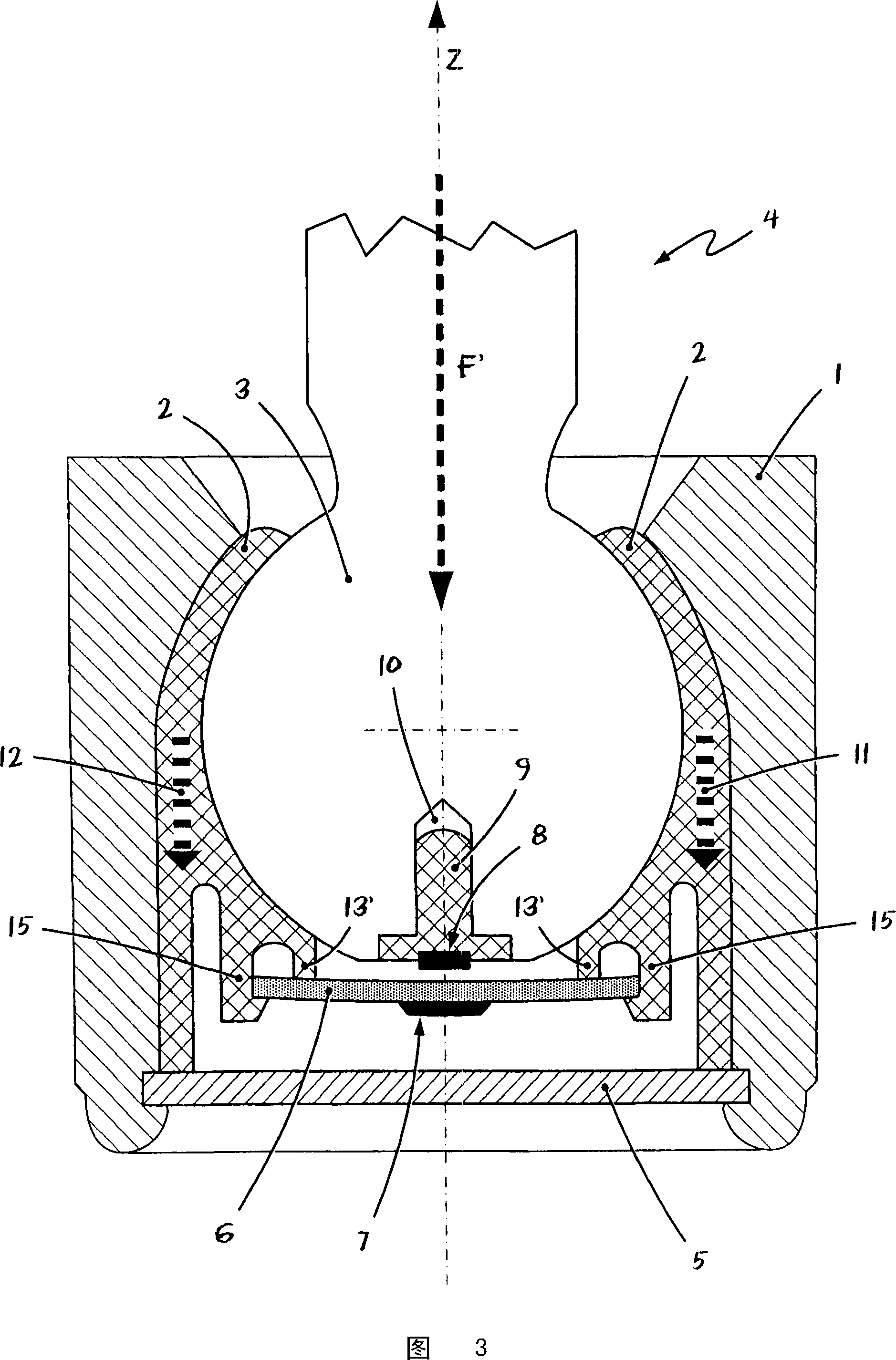

[0042] FIG. 1 shows a schematic longitudinal section through an embodiment of a ball joint according to the invention. Here, a substantially pot-shaped joint housing 1 can be seen, which has a bearing shell or spherical bush 2 arranged therein. The ball 3 of the spherical pin 4 is again arranged in the interior of the spherical bush 2 .

[0043] Furthermore, the ball joint according to FIG. 1 has a sensor printed circuit board 6 arranged between the joint ball 3 and the housing cover 5 . A sensor device 7 , shown only schematically, is arranged on the sensor printed circuit board 6 . The sensor device 7 is located in the vicinity of a magnetic field emitter 8 designed as a permanent magnet, which is arranged in a bore 10 of the joint ball 3 by means of a plastic plug 9 .

[0044] In this case, the sensor device 7 is designed in such a way that it can detect the magnetic field of the permanent magnet 8 in all three directions in space, in other words, it can detect the magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com