Culture substrate

A technology for cultivating substrates and cultures, which is applied in the direction of tissue cell/virus culture devices, biochemical instruments, biochemical equipment and methods, etc., which can solve the problems of uneven size and achieve the effect of effective spheroid culture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

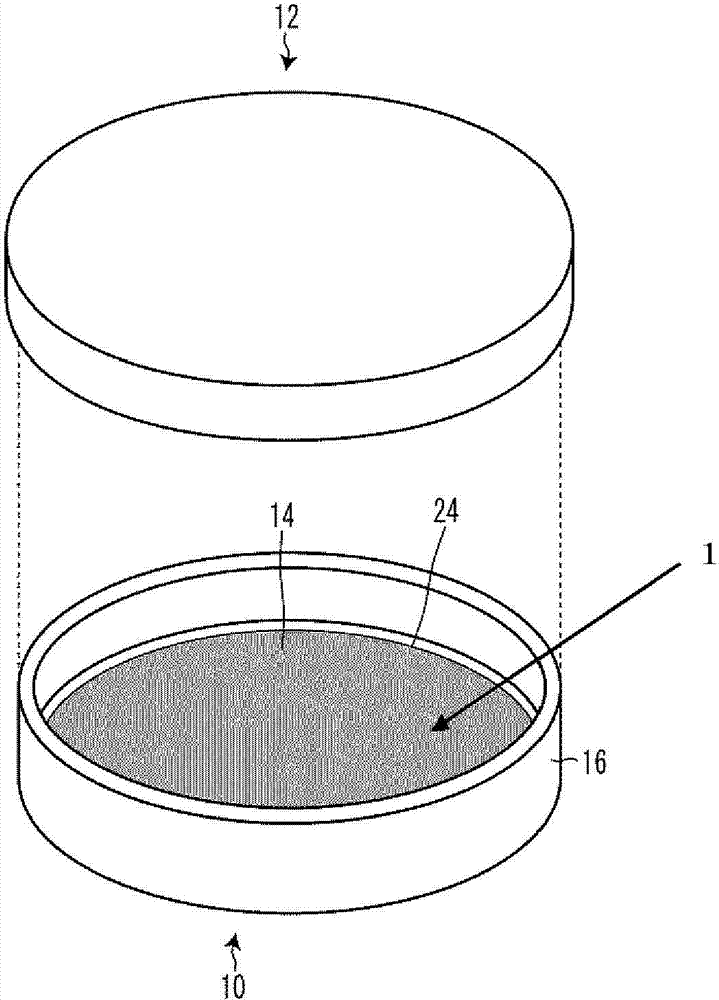

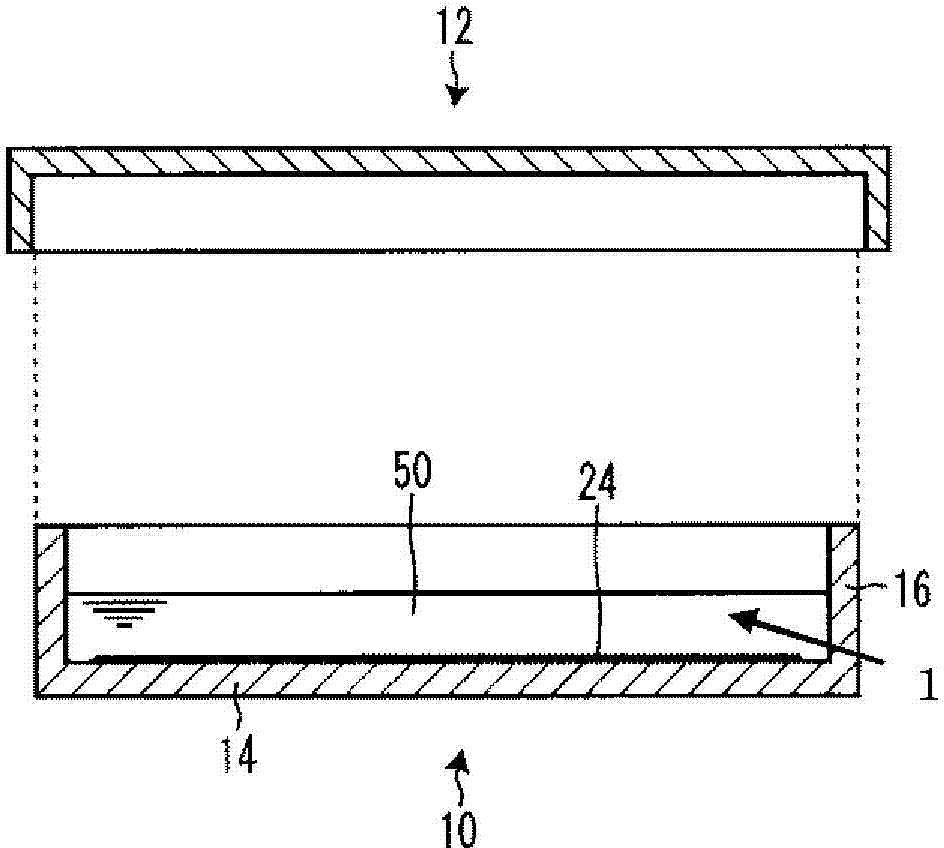

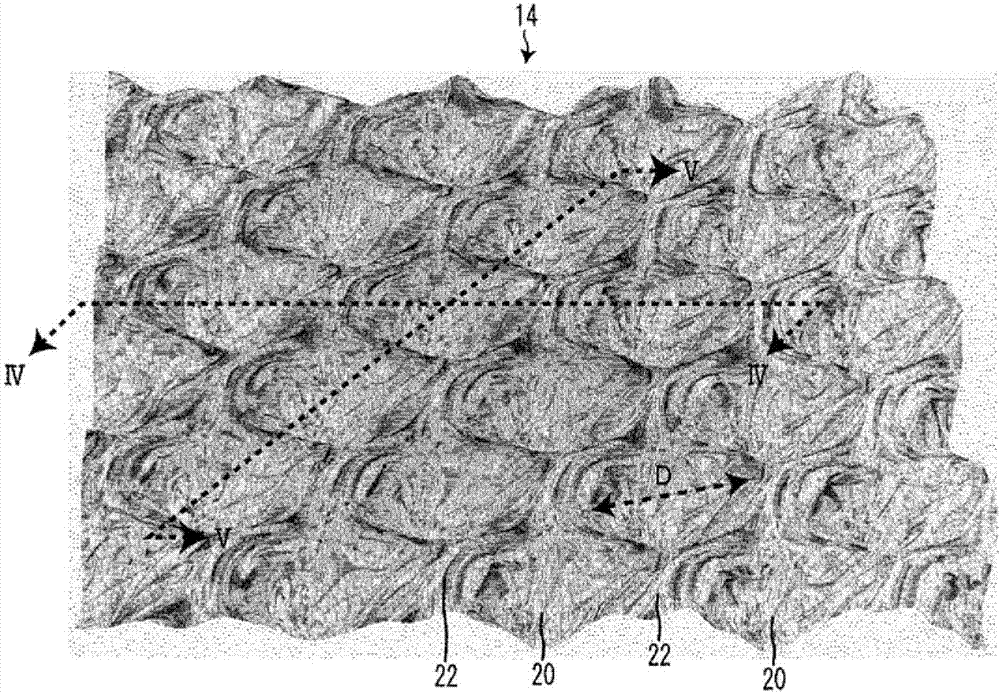

[0028] use Figure 1 to Figure 6 The culture substrate of the first embodiment of the present invention will be described.

[0029] figure 1 It is a perspective view of a culture container having the culture substrate of the present invention. figure 2 It is a longitudinal sectional view of a culture container. image 3 It is a partial perspective view of the pore formation region of the culture substrate. Figure 4 Yes image 3 Section view of IV-IV direction. Figure 5 Yes image 3 The V-V direction view sectional view. Image 6 It is a plan view showing the irradiation spot of the irradiated laser light on the surface of the culture substrate.

[0030] The culture substrate 1 of the present embodiment is a main part of a culture vessel for producing a spheroid (cell aggregate) formed by culturing cells and three-dimensionally aggregating them.

[0031] First, the characteristics of the culture substrate 1 of the present embodiment will be described.

[0032] like...

no. 2 Embodiment approach

[0056] use Figure 7 The culture substrate of the first embodiment of the present invention will be described. Figure 7 It is a partial sectional view of the pore formation region of the culture substrate. It should be noted that the present embodiment is a modified example of the first embodiment, and the same or similar parts as those of the first embodiment are assigned the same reference numerals, and repeated description thereof will be omitted.

[0057] In the first embodiment, the plurality of dimples 20 and banks 22 are formed by irradiating the surface of the culture substrate with laser light. On the other hand, in the present embodiment, the culture substrate 1 is obtained by injection-molding a synthetic resin material using a mold having a convex portion for forming the plurality of dimples 20 and a concave portion for forming the bank portion 22 . The plurality of dimples 20 and dams 22 are formed simultaneously with the molding of the culture substrate 1 .

...

no. 3 Embodiment approach

[0060] use Figure 8 The culture substrate of the first embodiment of the present invention will be described. Figure 8 It is a longitudinal sectional view of a state in which a culture substrate is set in a petri dish. It should be noted that the present embodiment is a modified example of the first embodiment, and the same or similar parts as those of the first embodiment are assigned the same reference numerals, and repeated description thereof will be omitted.

[0061] In the culture substrate 1 of the first embodiment, a plurality of wells 20 are formed on the inner bottom surface (the upper surface of the bottom plate 14 ) of the culture container. On the other hand, the culture substrate 1 of the present embodiment is formed of a disc-shaped synthetic resin material. In the culture substrate 1 , a plurality of dimples 20 are formed on one surface of the culture substrate 1 by injecting a synthetic resin material into a disk-shaped substrate and then irradiating one s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com