Combined type sensor devices and quantitative degassing apparatus

A sensor device and degassing device technology, applied in the field of sensors, can solve the problems affecting the accuracy of measuring the density of mud, easy to damage, inconvenient installation, use and maintenance, etc., to avoid unstable degassing efficiency, easy to use and install. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

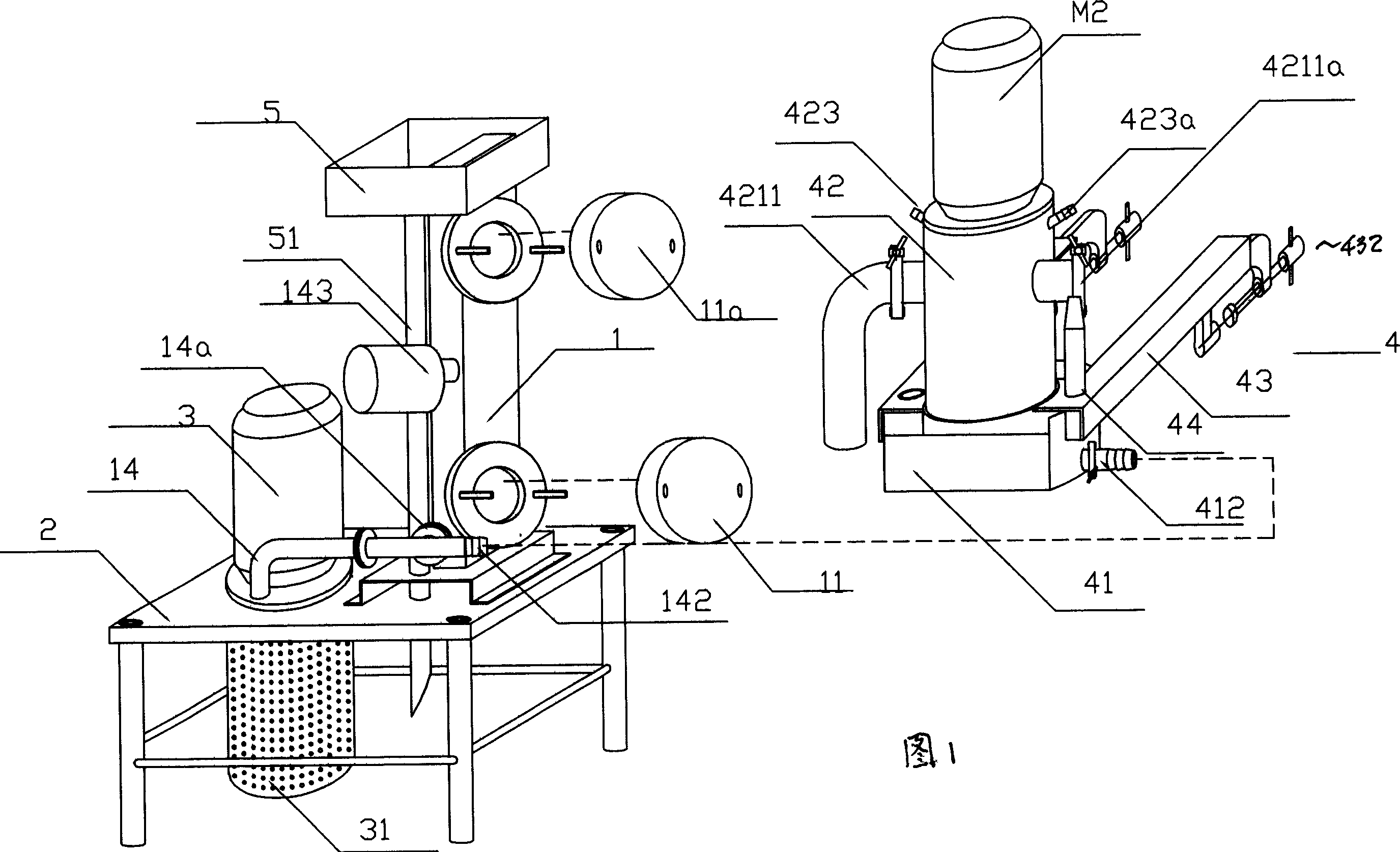

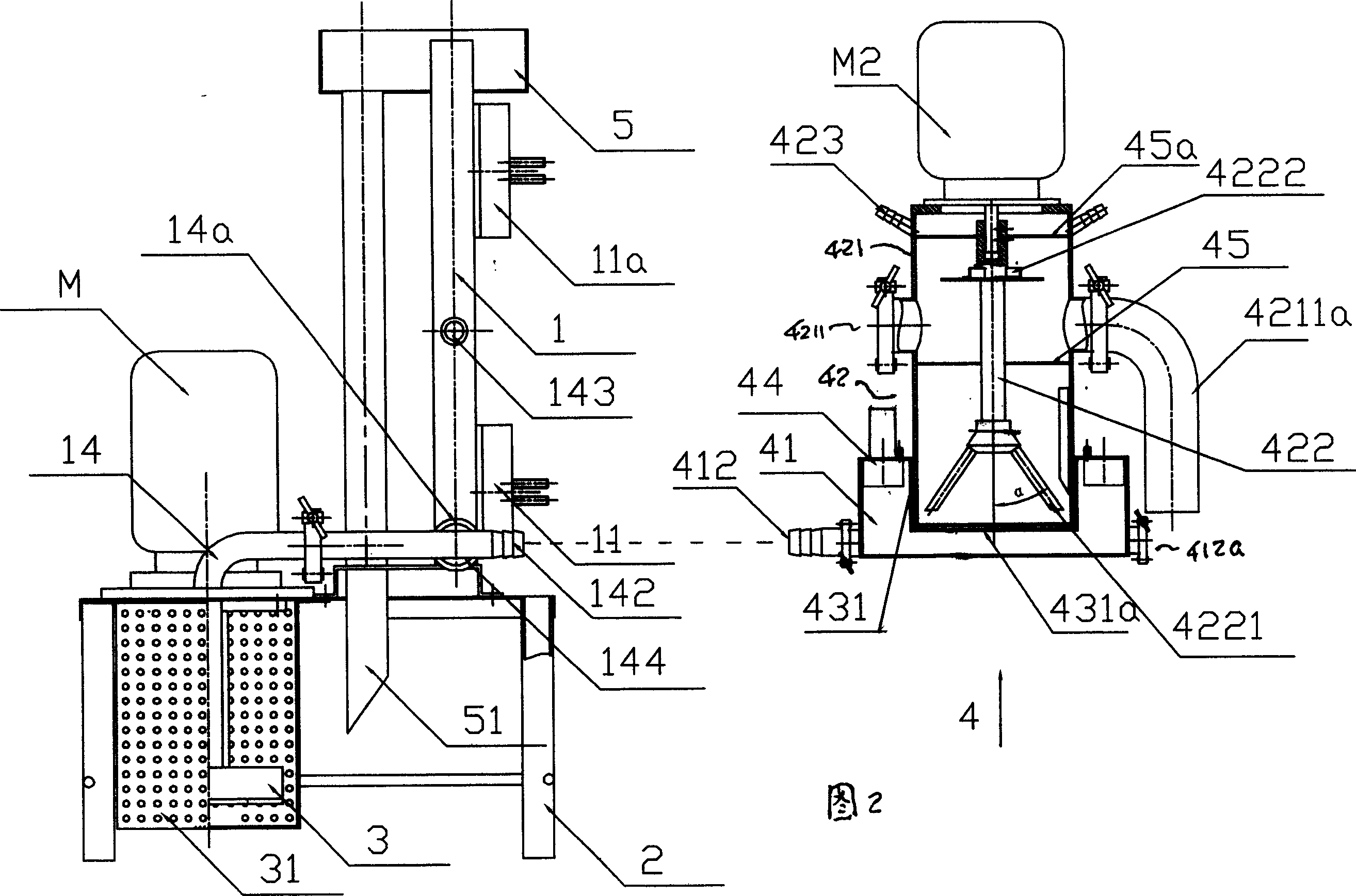

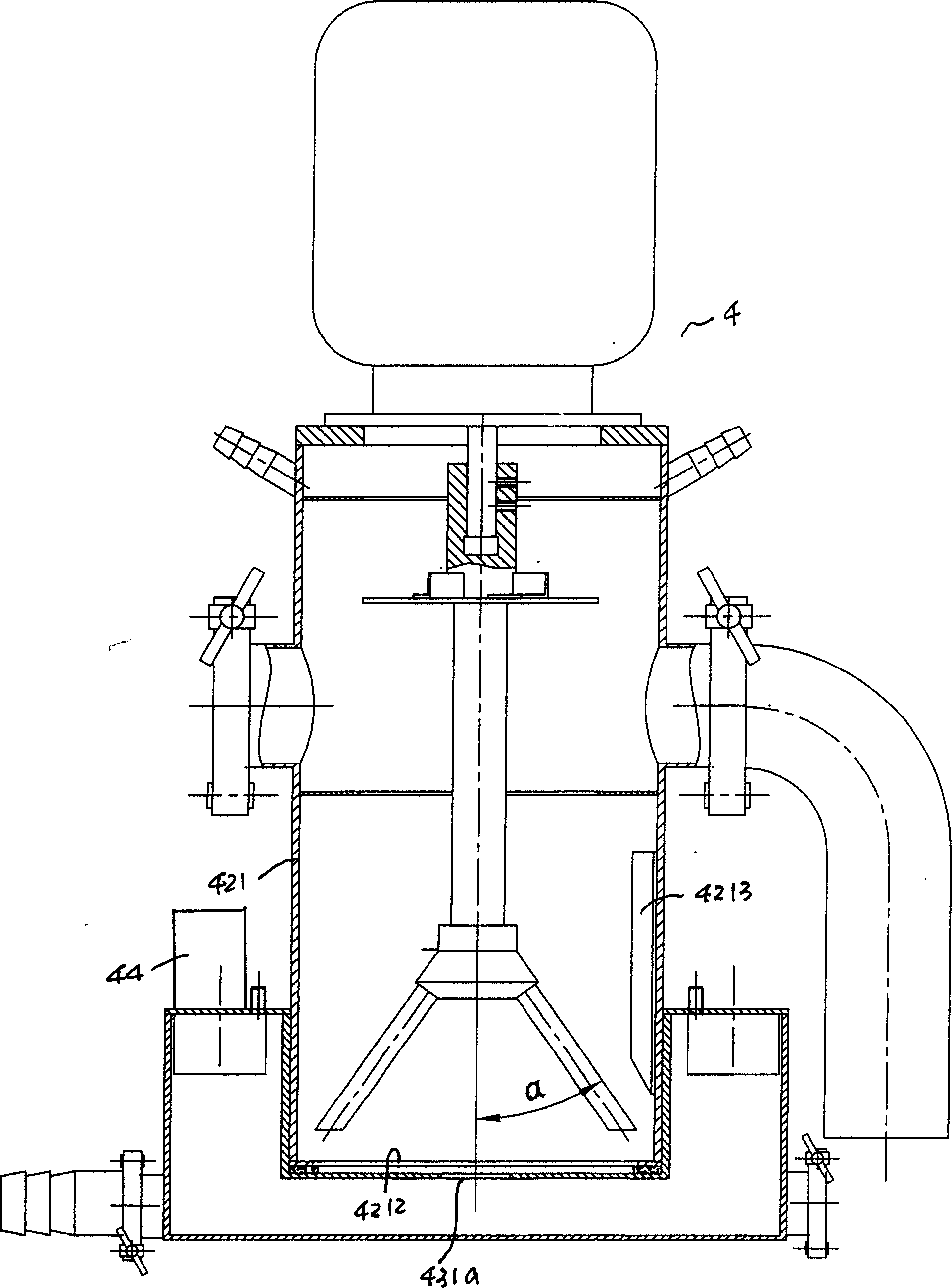

[0032] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

[0033] Please see Figure 1-3, a combined sensor device, including a detection container 1, wherein,

[0034] The detection container 1 is arranged on the support body 2;

[0035] A mud pump 3 is driven by the first motor M, installed through the bracket 2, and installed with the pump body at the bottom and the motor at the top;

[0036] A filter cover 31 is installed on the outside of the mud pump 3 to filter the sand debris mud from downhole;

[0037] A conveying pipe 14 protrudes from the filter cover 31 to convey the filtered downhole raw slurry liquid pumped out by the mud pump 3; Connected to deliver the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com