On-line degasser for transformer oil gas

A technology of transformer oil and degassing device, which is applied in the directions of liquid degassing, chemical instruments and methods, separation methods, etc., can solve the problems of high system cost and great influence of the degree of collection of degassing gas, and achieves optimized control strategy and satisfied repeatability. and stability requirements, the effect of reducing the dead volume of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples. Those skilled in the art can make various changes or modifications to the present invention, and these equivalent forms are also within the scope of the claims listed in this application.

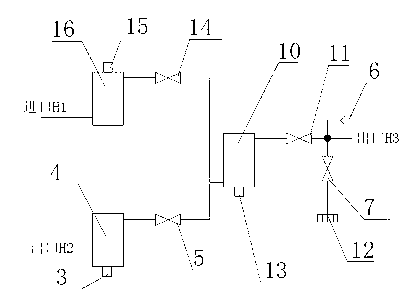

[0023] Explanation of symbols in the accompanying drawings: 4-oil discharge chamber, 6-exhaust outlet, 7-pressure sensor, 10-degassing chamber, 16-quantitative chamber, 3, 13, 15-liquid level sensor, 5, 11, 14 -Solenoid valve, H1-oil inlet, H2-oil outlet, H3-sample gas outlet.

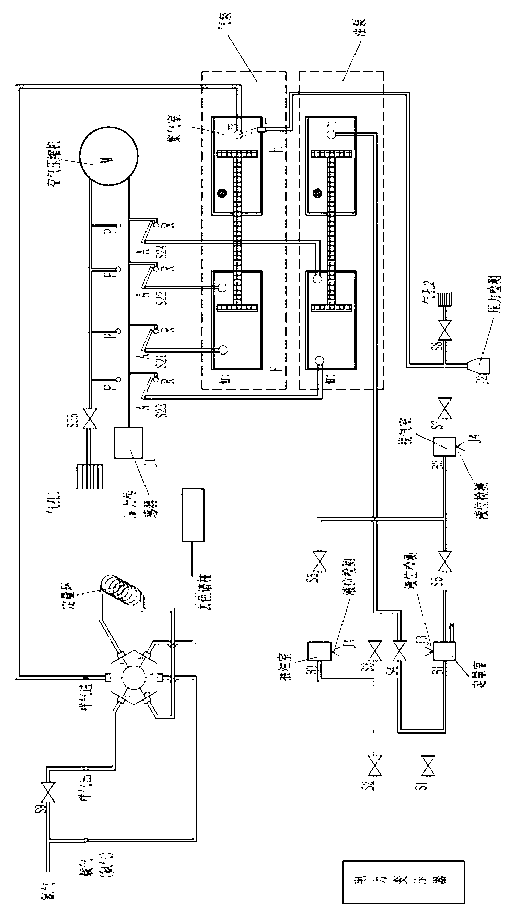

[0024] like figure 1 As shown, this embodiment includes: an oil pump, an air pump, an air compressor, a quantitative chamber, a degassing chamber, an oil discharge chamber, a pressure sensor, a liquid level sensor, a pipeline, a solenoid valve and an electric control device, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com