Device for coating heat-conducting silicone grease on radiation surface of insulated gate bipolar translator (IGBT) module and related coating method

A heat-conducting silicone grease and heat-dissipating surface technology, which is applied to the device and coating of the surface coating liquid, can solve the problem of affecting the heat dissipation quality of the IGBT module, the thickness and uniformity of the coating cannot be guaranteed, and the change of the bolt tightening torque value, etc. problems, to achieve the effect of ingenious design, simple structure and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

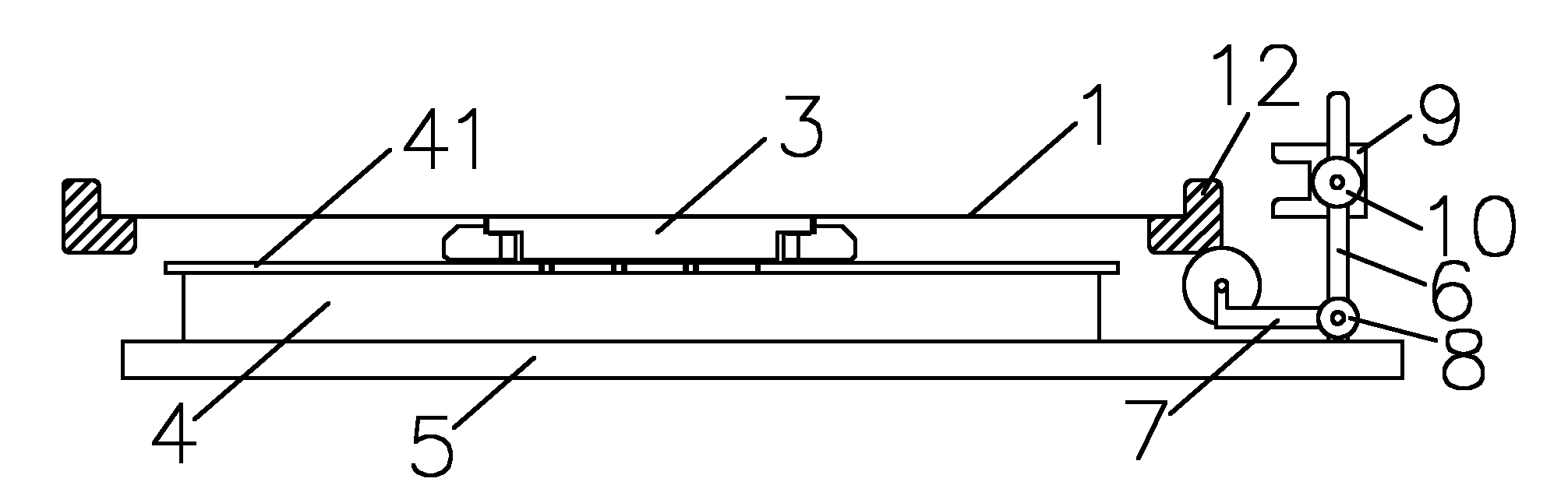

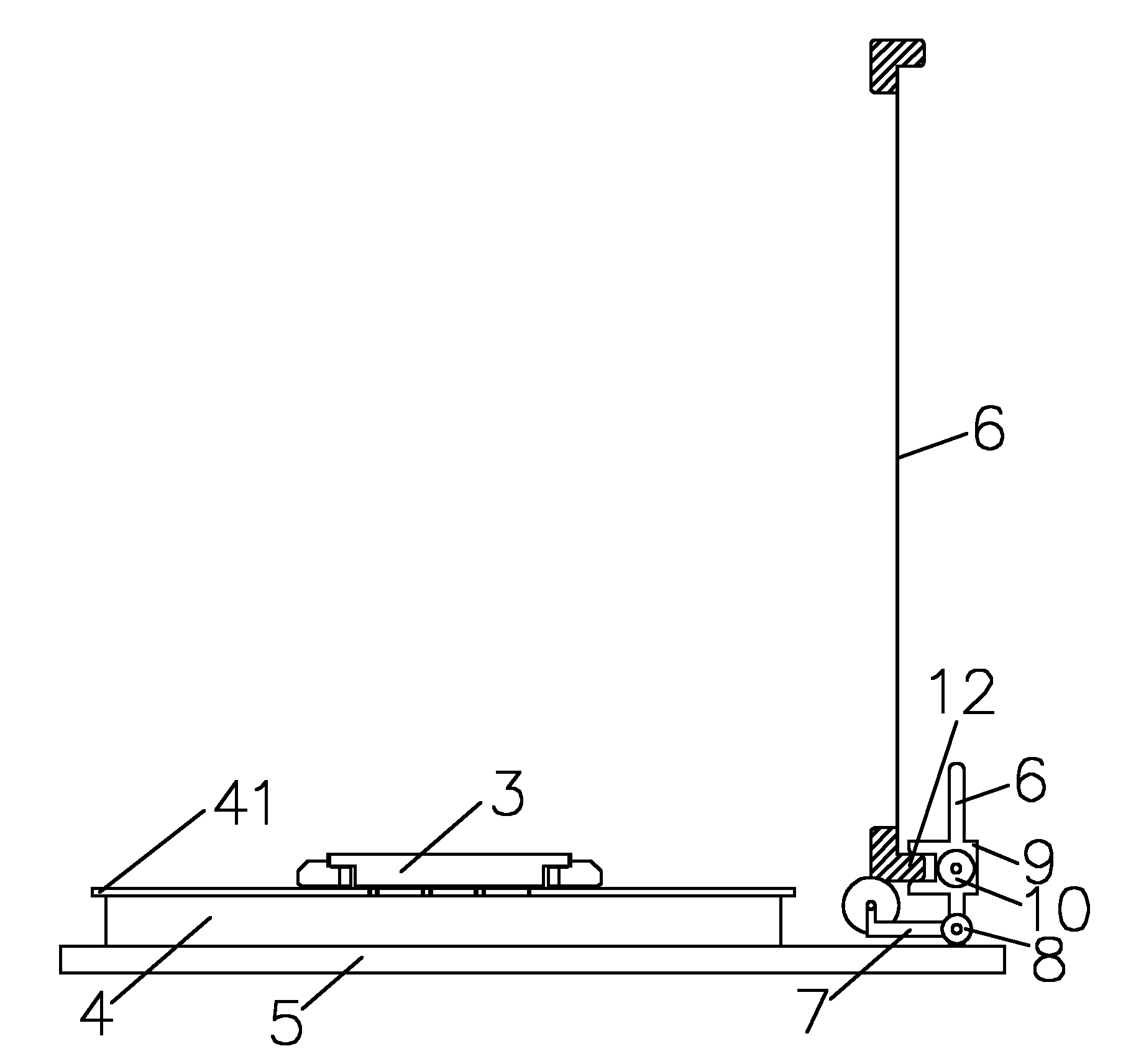

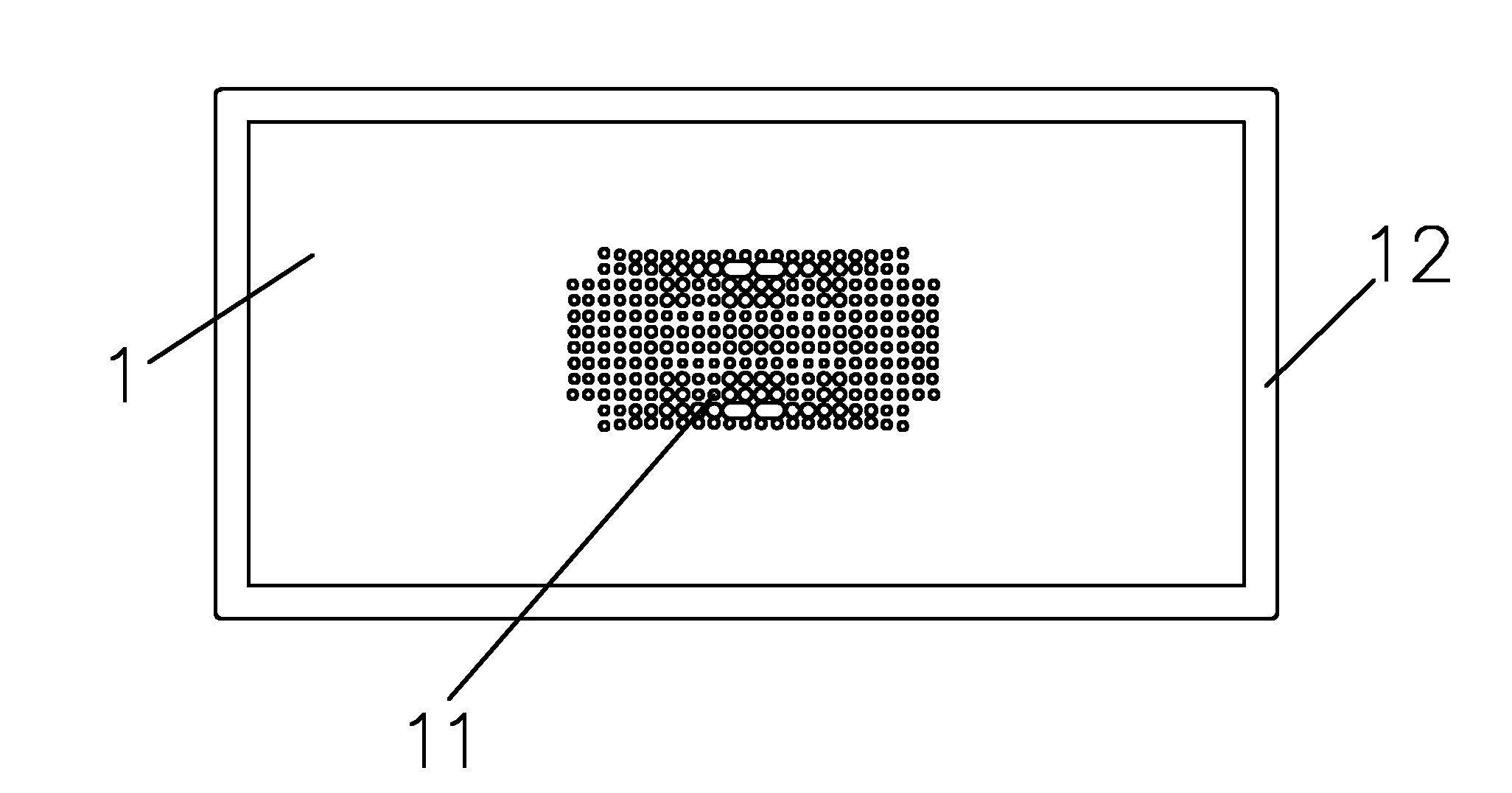

[0037] See Figure 1-3 As shown, the device of the present invention for coating thermally conductive silicone grease on the heat dissipation surface of an IGBT module includes a mesh plate 1 and a mesh filling tool 2, and the mesh plate 1 is provided with a 3 the mesh area 11 on the heat dissipation surface, the mesh filling tool 2 is used in conjunction with the mesh area 11 to fill the mesh area with the thermal conductive silicone grease when applying the thermal conductive silicone grease 11 meshes.

[0038] The thickness H of the mesh area 11 2 The coating thickness H of thermal conductive silicone grease can be customized according to the needs 1 Sure. In a specific embodiment of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com