A new type of rotating drive system for mixing drum of concrete mixer truck

A mixer truck, rotary drive technology, applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve the problems of destroying the quality of commercial concrete, excessive exhaust gas, and large energy consumption, and avoid inefficiencies. The effect of long-term work, not too expensive, and improved economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

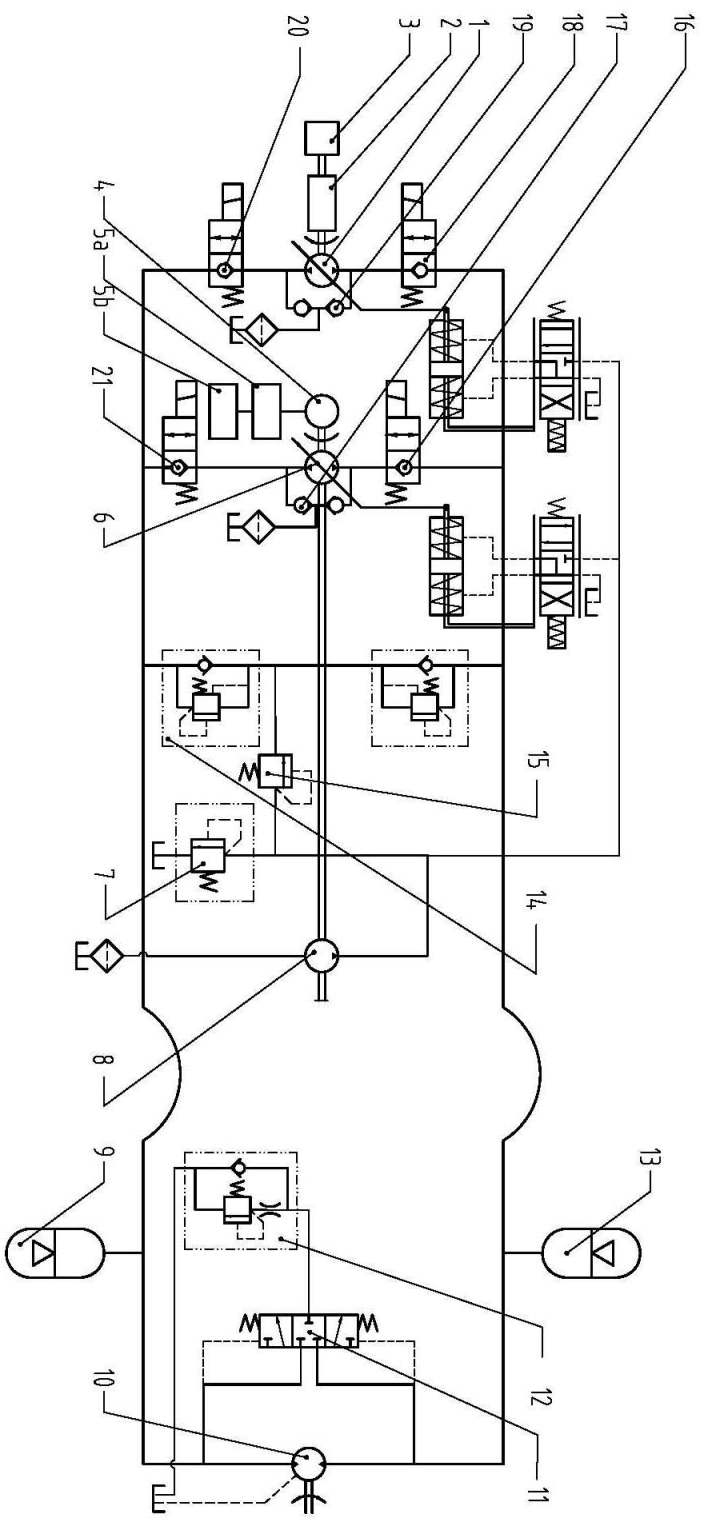

[0087] Such as figure 1 As shown, a new type of concrete mixer truck mixing drum rotation drive system. This scheme is based on the traditional single pump-motor closed circuit acceleration and deceleration scheme, adding a small displacement hydraulic main pump to form a double pump parallel closed circuit to drive the hydraulic motor and transmit power through the hydraulic motor to the reducer, and then the reducer drives the mixing drum. The small-displacement hydraulic main pump is driven by a small-power independent prime mover power system, and the high-power prime mover power system drives a large-displacement hydraulic main pump. The oil inlet and outlet of the large and small-displacement hydraulic main pumps are connected in parallel. The high-power prime mover power system mainly includes: the chassis engine 3 is connected to the servo variable pump 1 through the power take-off 2 (or the servo variable pump 1 is directly driven by an independent high-power engine...

specific Embodiment approach 2

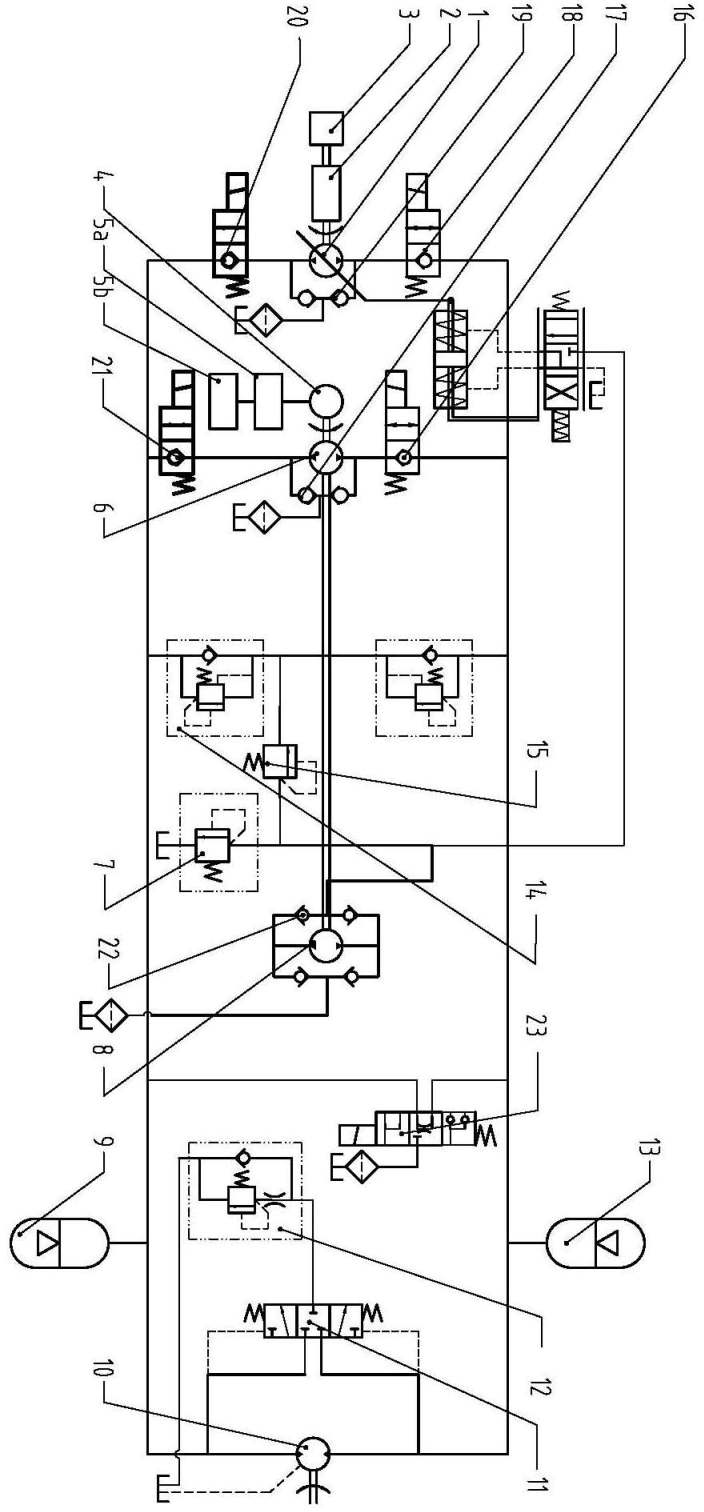

[0094] Such as figure 2 As shown, the main components and connections of the high-power prime mover power system are the same as the first scheme; the high-power prime mover can be a chassis engine, an independent high-power electric motor or an independent high-power engine. The low-power prime mover power system here is the electric motor power system, mainly including: battery 5b, motor controller 5a, independent small-power motor 4, two-way quantitative pump 6, oil charge pump 8, two-position two-way electromagnetic or electro-hydraulic reversing valve 16, 21 and the bridge circuit 22 composed of one-way valves drive the two-way quantitative hydraulic motor 10; the battery 5b controls the independent small-power motor 4, the two-way quantitative pump 6 and the charge pump through the motor controller such as the frequency converter 5a 8 can be selected to be connected with the same axis. Also in order to reduce the influence of the system pressure on the two-way quantitat...

specific Embodiment approach 3

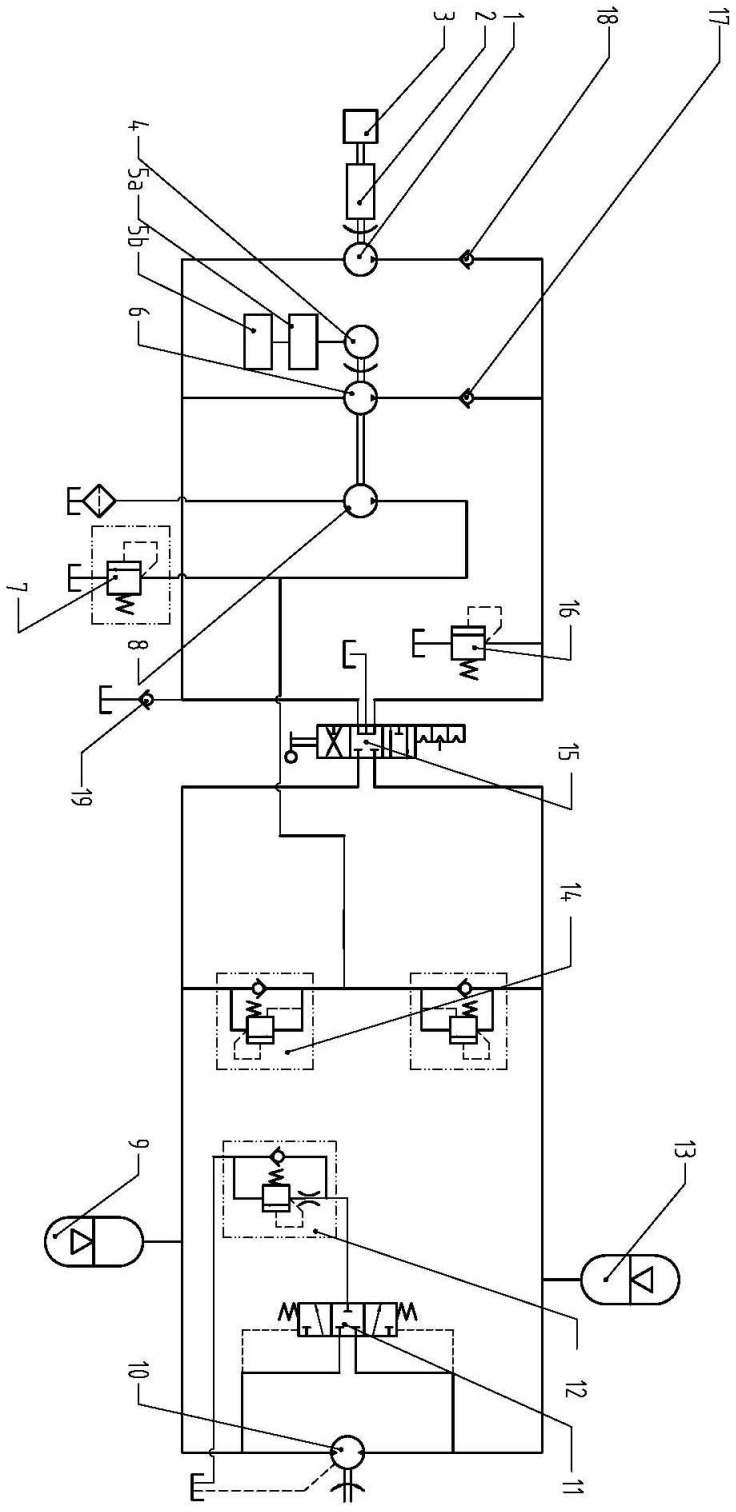

[0100] Such as image 3 As shown, the high-power prime mover power system refers to the chassis engine power system or a high-power independent prime mover power system such as a high-power independent engine or a high-power independent electric motor drive system. When the high-power prime mover is a chassis engine, the chassis engine power system mainly includes: chassis engine 3, power take-off 2, one-way quantitative pump 1, one-way valve 18, chassis engine 3 is connected to quantitative pump 1 through power take-off 2 , in order to reduce the influence of system pressure on the large-displacement main pump 1, a check valve 18 is installed at the outlet of the large-displacement quantitative pump 1; when the high-power prime mover is an independent high-power engine, the independent high-power engine power system It mainly includes: an independent high-power engine, a quantitative pump 1, and a check valve 18. The independent high-power engine is connected to the quantitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com