Automatic coating machine for shoe industry and automatic coating production line

A kind of coating machine and automatic technology, which is applied in the direction of shoemaking machinery, devices for coating liquid on the surface, footwear, etc., can solve the problems of enterprise hidden dangers, high labor costs, low production efficiency, etc., and improve production efficiency , avoiding occupational diseases, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

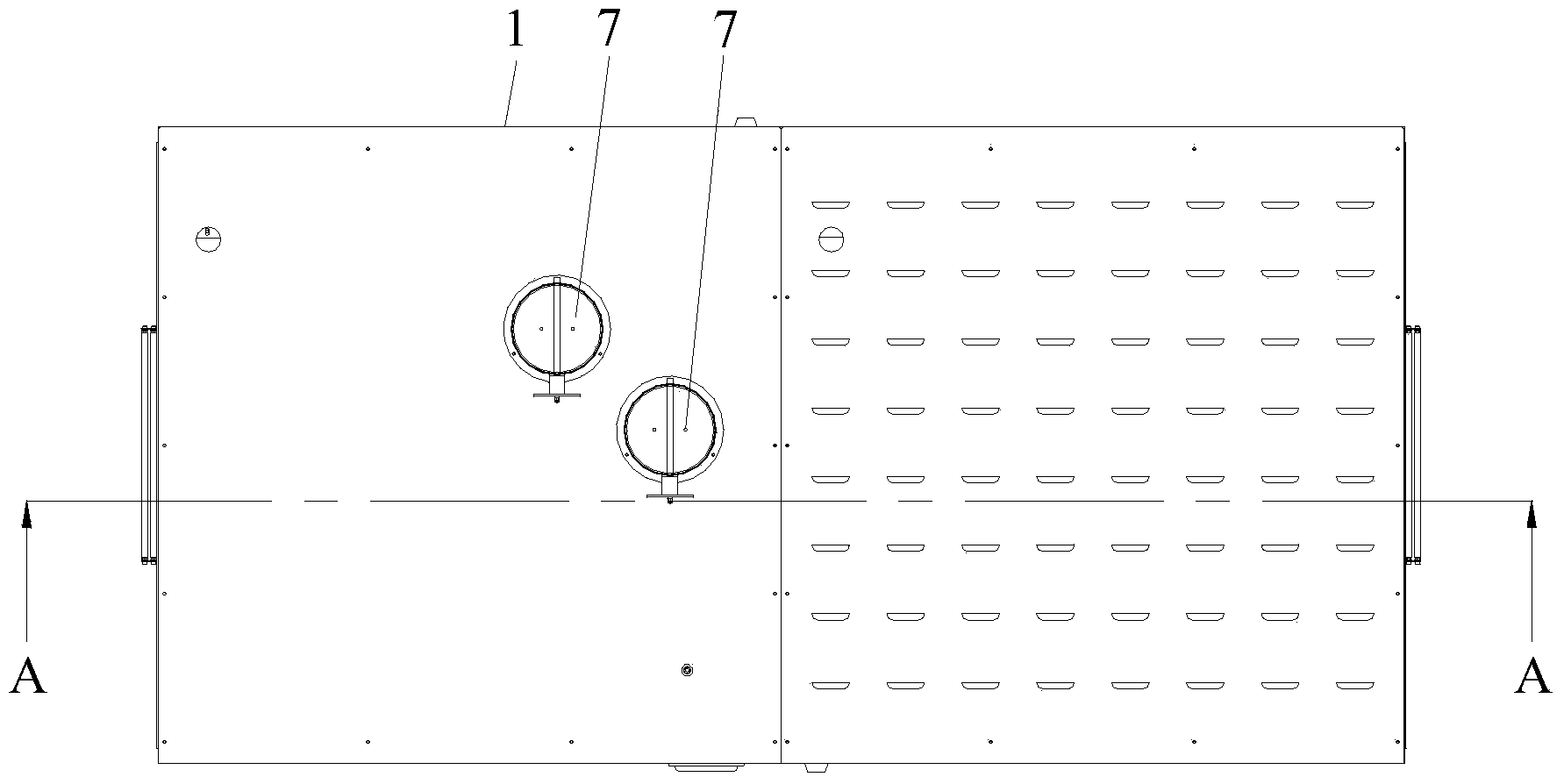

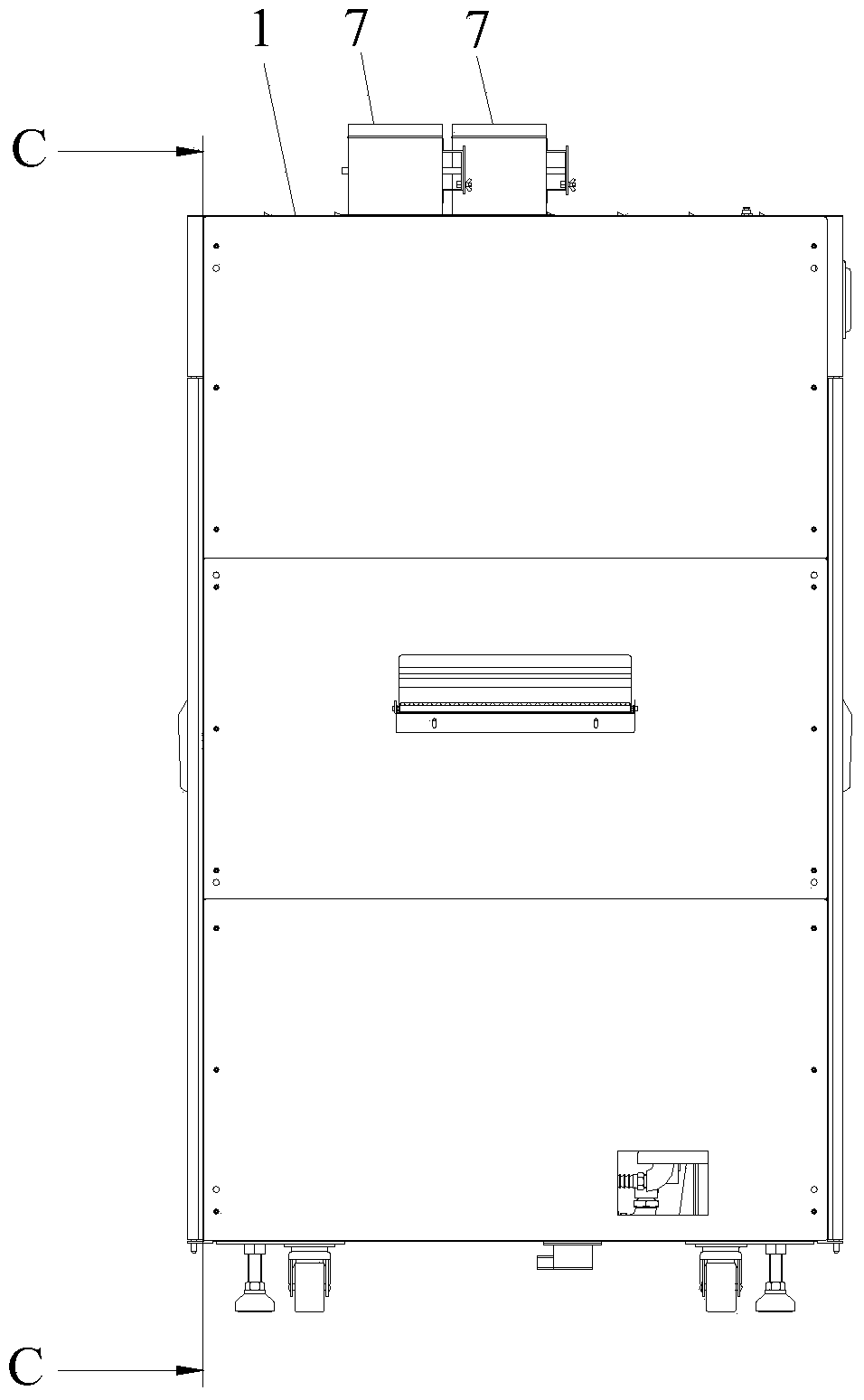

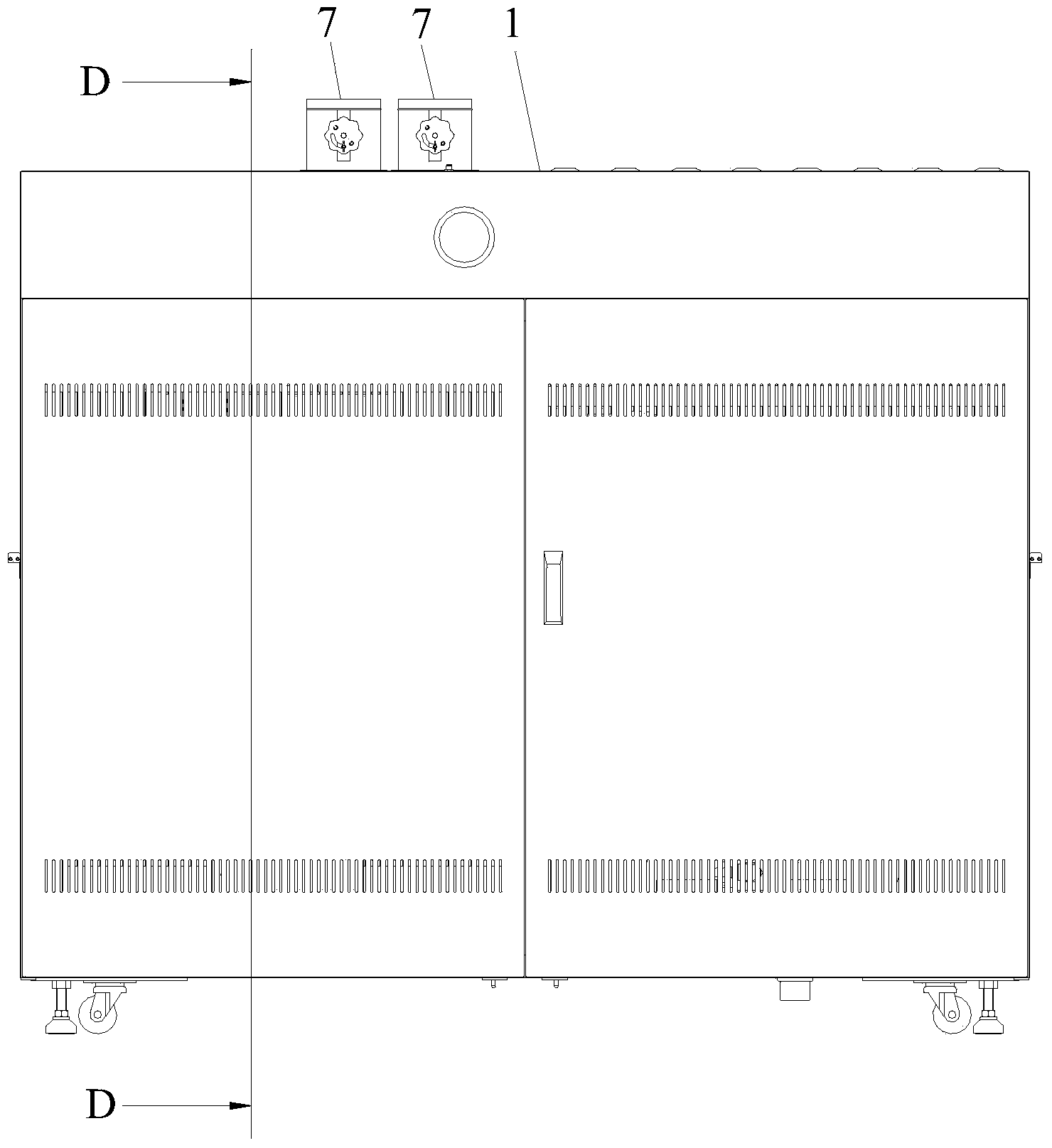

[0024] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0025] Please refer to Figure 1-6 , the automatic coating machine 100 for the shoe industry includes a casing 1, a horizontal conveying path is arranged in the casing 1, an automatic coating part 2, a conveying part 3, and a control automatic coating part are also arranged in the casing 1 The flow control part 4, the air knife part 5 and the net washing part 6 of the treatment agent supply amount of 2. The outer top of the housing 1 is provided with an exhaust part 7, and the exhaust part 7 is connected to the area where the automatic coating part 2 is located through a pipe.

[0026] The automatic coating part 2 is located at the front of the horizontal conveying path and distributed on the upper and lower sides of the horizontal conveying path, and forms a coating area 21 coincident with the horizontal conveying path....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com