Vibrating spear with modularized front-mounted power low-vibration vibrating head

A front-mounted power and vibrating head technology, which is applied to the processing of electromechanical devices, electric components, and building materials, can solve problems such as troublesome disassembly and maintenance, increased purchase costs, and operator injuries, so as to reduce manufacturing costs and shorten The effect of transmission distance and reduction of vibration intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

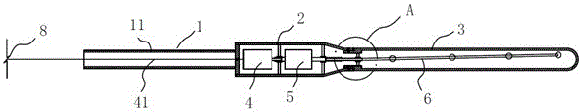

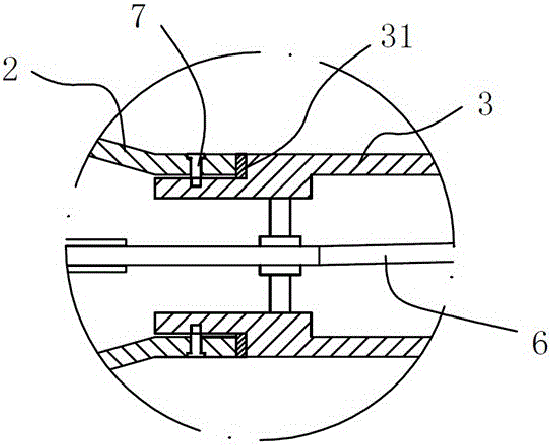

[0021] like figure 2 and 3 As shown, a modular vibrating rod with front power and low vibration vibrating head is composed of a hand-held part 1 , an intermediate body 2 and a vibrating head 3 connected in sequence. The handle 1 is covered with a leather sheath 11 for increasing the comfort of operation. The intermediate body 2 is provided with a driving small motor 4 and a speed change gear set 5, and the output shaft of the small motor 4 is connected with a steel cable 6 extending into the vibrating head through the speed change gear set 5.

[0022] The present invention breaks the drawbacks of the existing motor back-end drive, and it is a front-end drive structure of the motor. The small motor 4 is directly connected with the steel cable 6 in the vibrating head 3 through the speed change gear set 5 . This structural arrangement makes the entire transmission of the vibrating rod not need to pass through the hand-held part 1, which can effectively reduce the vibration int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com