Pneumatic hoisting and emptying device of finished product cabin

A technology of pneumatic lifting and discharging devices, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the external environmental threats to the physical and mental health of post personnel, increase the steps of manual cleaning, increase the labor load of post workers, etc., and achieve improvement on the spot Sanitation, avoidance of occupational diseases, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

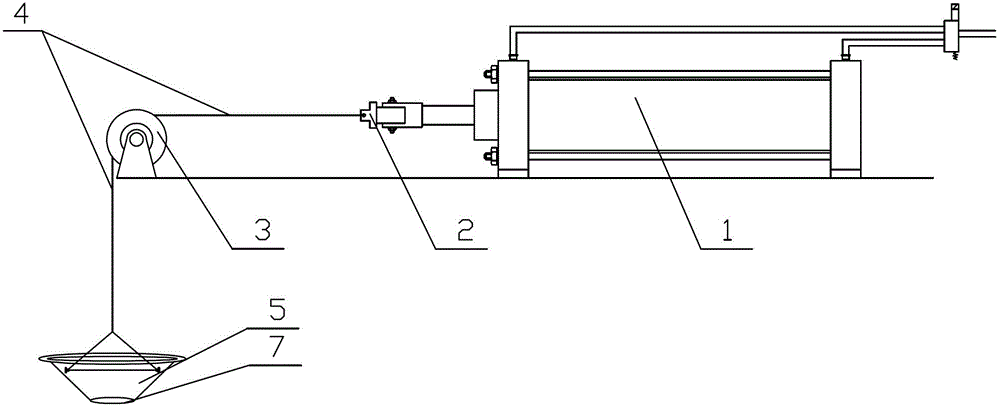

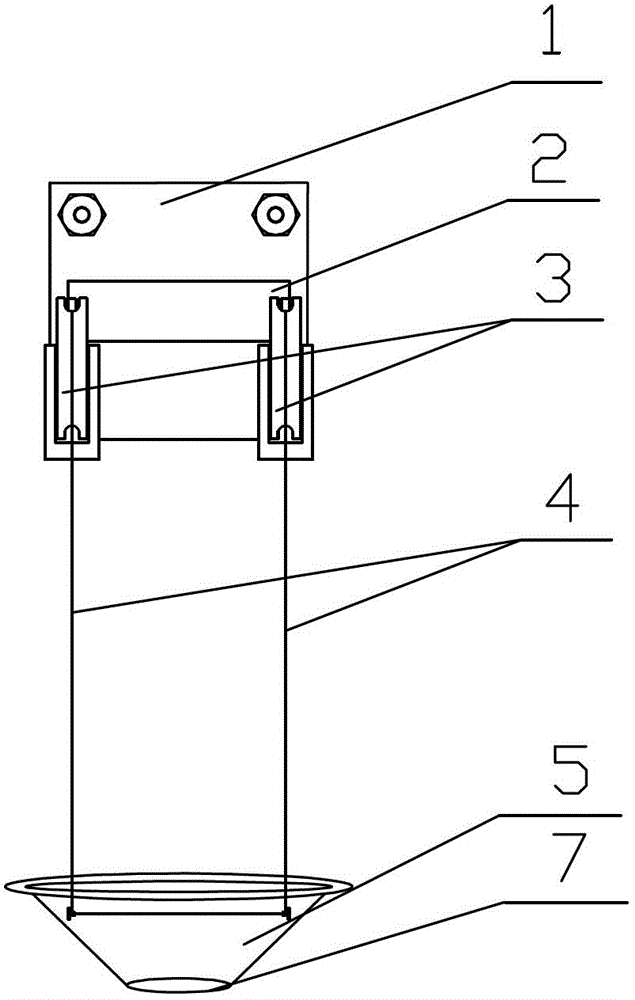

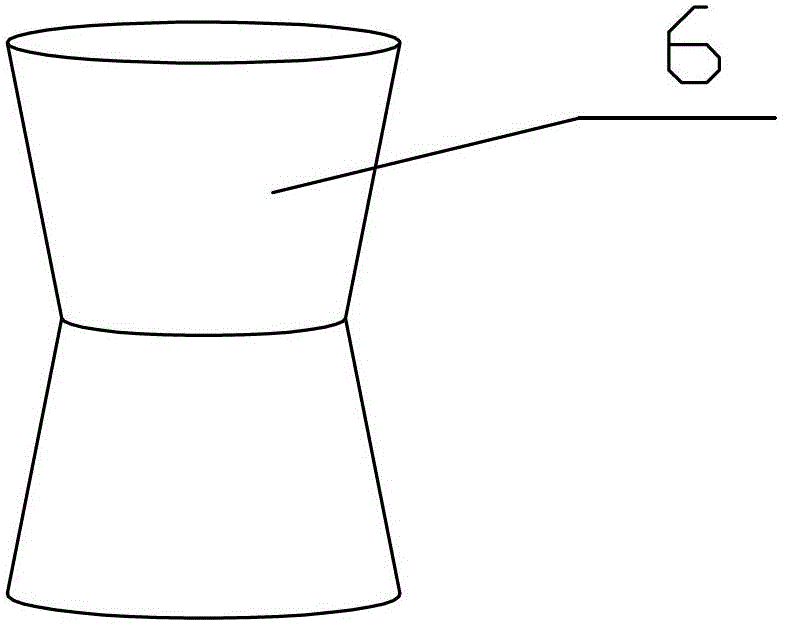

[0012] The finished product warehouse pneumatic lifting and discharging device provided in this embodiment has a structure as shown in the figure, including a cylinder 1 and two sets of pulley devices, wherein the front end of the cylinder is provided with an external plastic-coated wire rope gripper 2, and two sets of pulley devices The gripper is connected with the cylinder through the wire rope. Each set of pulley devices includes a steel wire rope 4 with a diameter of 6mm and a pulley 3, wherein the steel wire rope is installed on the pulley, and the pulley block is installed in the middle of the lower hopper to ensure balance during the lifting process, so that the lower hopper and the filling The car docks perfectly. The two sets of pulley devices have the same structure and are installed in parallel to ensure that the discharging device can work smoothly during use. Simultaneously, the front ends of the two wire ropes are connected with the wire rope grippers, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com