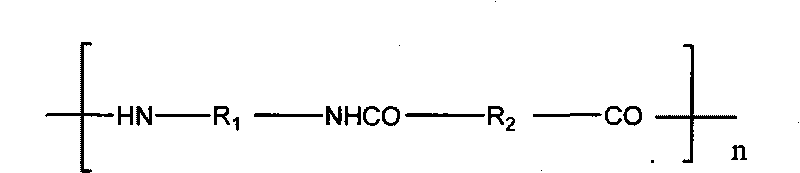

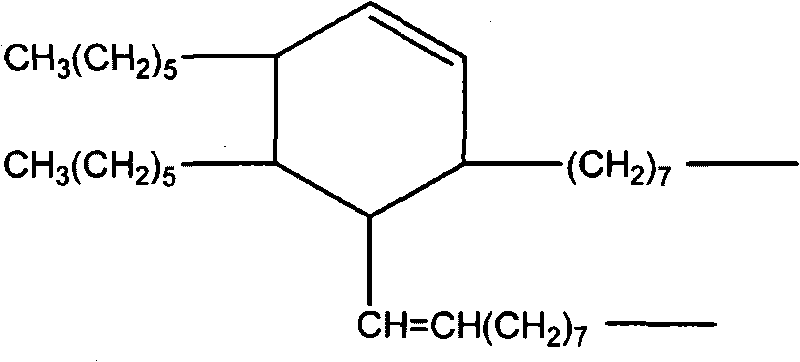

Soybean oil-based dimeric acid type polyamide hot melt adhesive and preparation method thereof

A technology of polyamide hot-melt adhesive and base dimer acid type, which is applied in the direction of adhesives, etc., can solve the problems of high crystallinity, unfavorable processing and molding, difficulty of semi-aromatic polyamide, poor low temperature resistance, etc., and achieve environmental protection , Good dimensional stability, and the effect of reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0044] 112g soy-based dimer acid (97%), 87.6g adipic acid, 65.8g azelaic acid, 11.9g acetic acid, 103.2g decanediamine, 69.3g 4,4'-diaminodiphenylmethane, 45.2g caprolactam , 29.7g water, 0.25g triphenyl phosphite, join in the polycondensation reactor, pass into the air in the nitrogen replacement still. The temperature is raised to 180°C, the pressure is raised to 1.0MPa, and the reaction is kept for 2.0 hours; the pressure continues to rise to 1.7MPa, the temperature is raised to 200°C, and the reaction is made for 1 hour; the pressure is reduced to normal pressure, the temperature is raised to 260°C, and the reaction is continued for 30 minutes ; The temperature was lowered to normal temperature, vacuumized for 10 minutes, and the dimer acid type polyamide hot melt adhesive was obtained from the discharge. The measured melting point was 117.5° C. and the relative viscosity was 1.8 dL / g.

Embodiment example 2

[0046] 112g soybean oil-based dimer acid (97%), 24g 2-methyl adipic acid, 54g undecanedioic acid, 7.8g propionic acid, 39.5g2,4,4-trimethylhexamethylenediamine, 31.8g 2 , 2'-dimethylbenzidinediamine, 56.4g 8-capryllactam, 17.9g water, and 0.4g hypophosphoric acid were added to the polycondensation reactor, and the air in the reactor was replaced by nitrogen gas. The temperature is raised to 190°C, the pressure is raised to 1.2MPa, and the reaction is kept for 2.5 hours; the pressure continues to rise to 1.7MPa, the temperature is raised to 210°C, and the reaction is 1.2 hours; the pressure is reduced to normal pressure, the temperature is raised to 260°C, and the reaction is continued for 40 Minutes; the temperature was lowered to normal temperature, vacuumized for 12 minutes, and the dimer acid type polyamide hot melt adhesive was obtained from the discharge, the measured melting point was 98°C, and the relative viscosity was 1.3dL / g.

Embodiment example 3

[0048] 112g soy-based dimer acid (97%), 54.4g pimelic acid, 75.6g undecanedioic acid, 10.4g lauric acid, 41g hexamethylenediamine, 72.1g 2,2'-dimethyl-4,4 '-Diaminodiphenylmethane, 45.2g of caprolactam, 31.2g of water, and 0.5g of phosphoric acid were added to the polycondensation reactor, and nitrogen was introduced to replace the air in the reactor. The temperature is raised to 200°C, the pressure is raised to 1.3MPa, and the reaction is kept for 3 hours; the pressure is continued to rise to 1.7MPa, the temperature is raised to 220°C, and the reaction is continued for 1.3 hours; the temperature is lowered to normal pressure, and the temperature is raised to 260°C, and the reaction is continued for 50 Minutes; the temperature was lowered to normal temperature, vacuumized for 15 minutes, and the dimer acid type polyamide hot melt adhesive was obtained from the discharge. The measured melting point was 113°C and the relative viscosity was 1.6dL / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com