Coating brushing machine

A glue brushing machine and machine head technology, which is applied to shoe-making machinery, clothing, and shoe bonding parts, etc., can solve problems such as difficulty in controlling the thickness of the glue surface and the size of the brush edge, affecting the appearance quality of the product, and large loss of glue. , to achieve the effect of stable appearance quality, compact structure and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

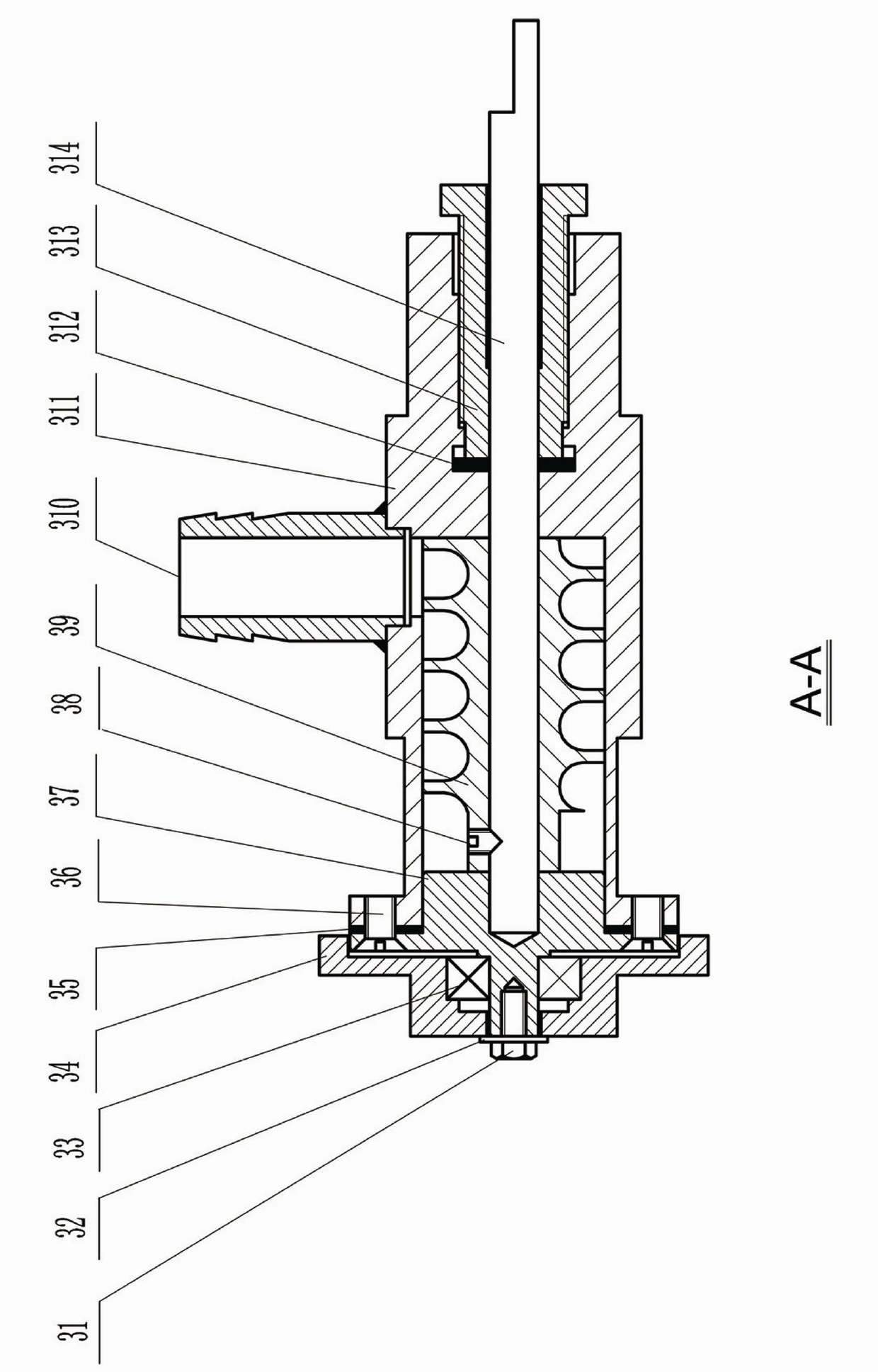

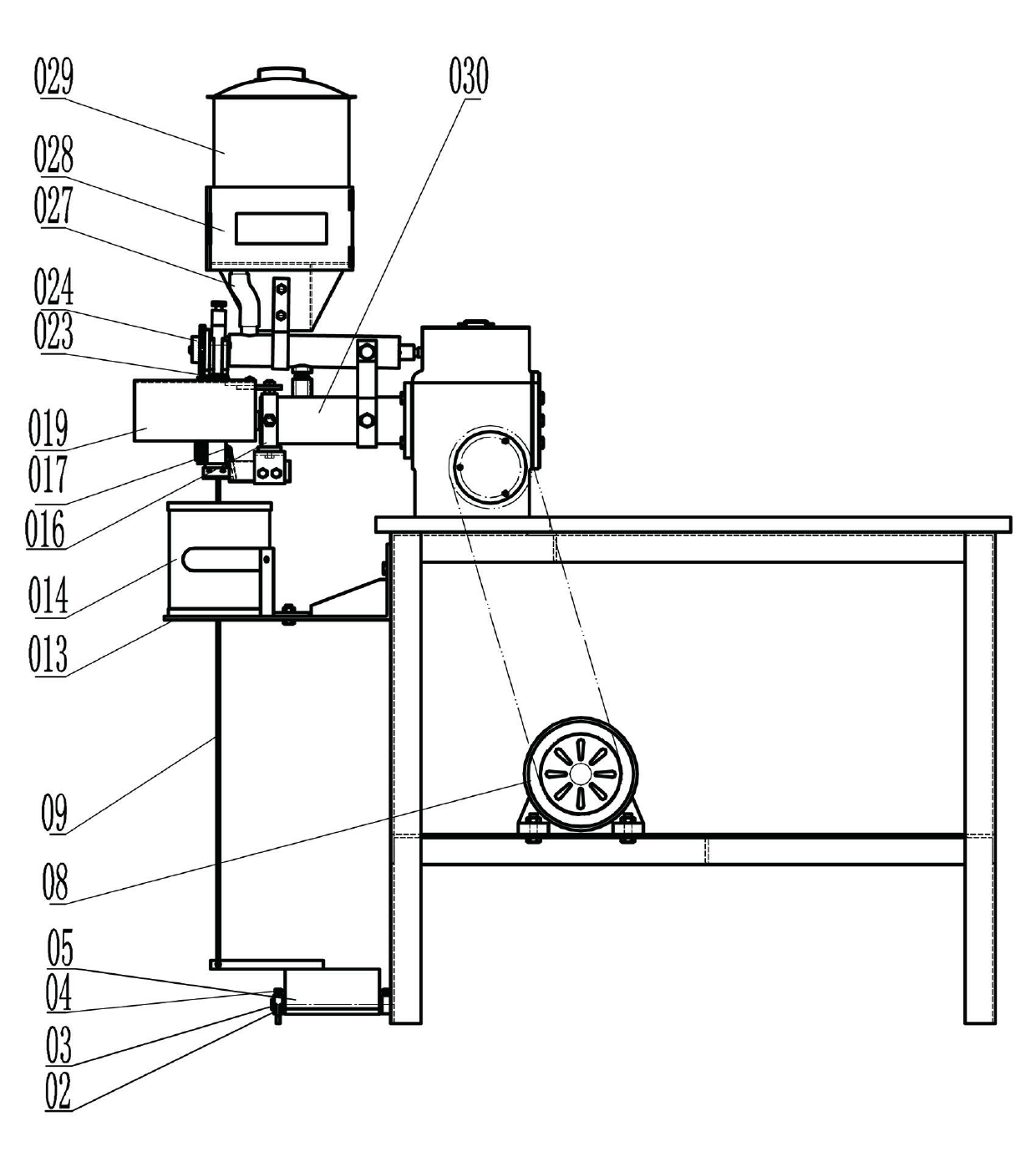

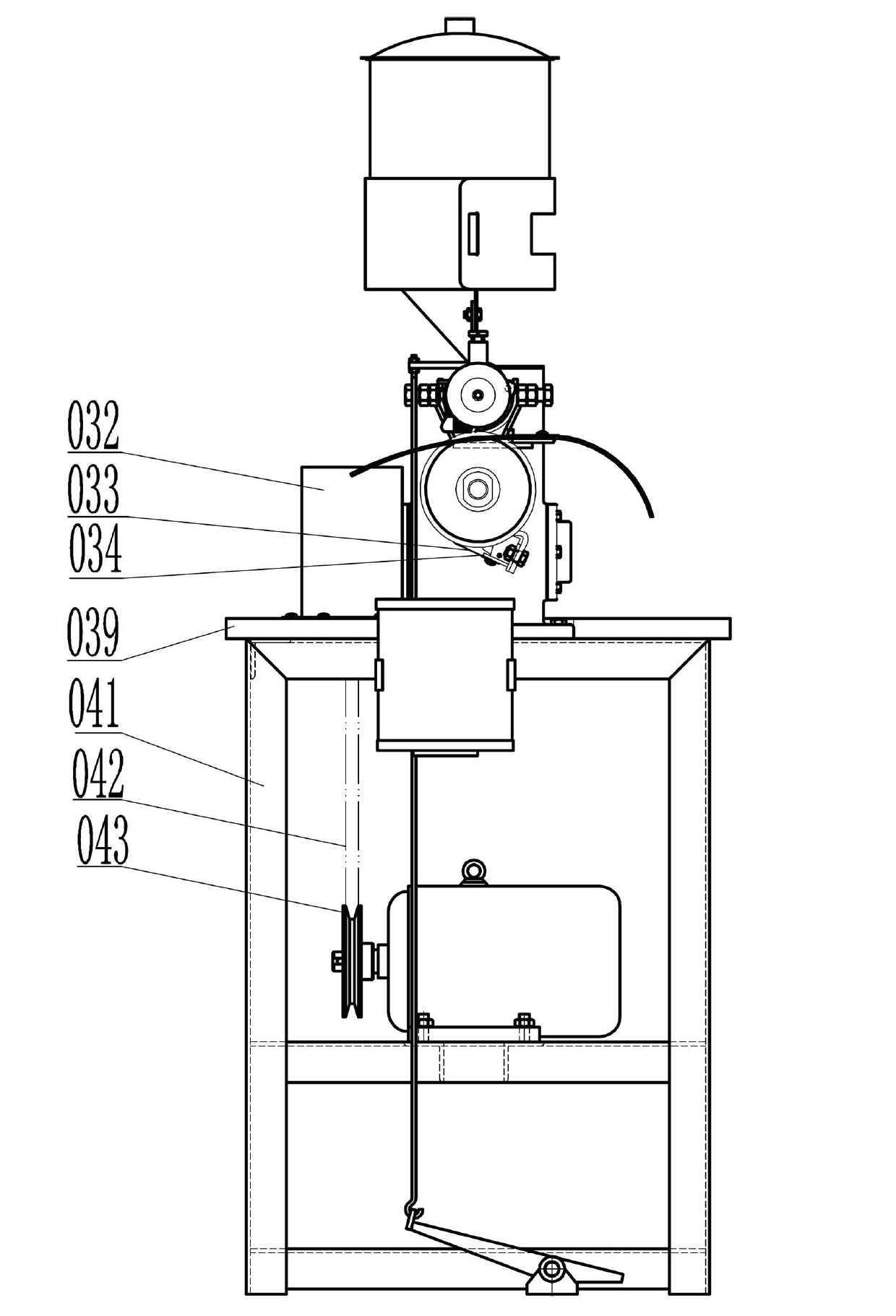

[0029] Depend on Figures 1 to 8 It can be seen that the present invention includes: frame 041, head device 030, electric transmission device, rubber storage device, manual transmission device, rubber head device 024, wherein:

[0030] The frame 041 is set on the ground, and the frame 041 is divided into two layers of support plates, the upper layer is equipped with a head device 030, the lower layer is equipped with an electric transmission device, and the side is fixedly equipped with a rubber bucket bracket 013;

[0031] The machine head device 030 is fixed on the support plate on the frame 041 through the machine head seat 224. The machine head device 030 includes the electric transmission mechanism of the machine head, the manual transmission mechanism of the machine head and the active rolling part, and the machine head device 030 is driven by the electric transmission device. The transmission part of the machine head and the active rolling part work;

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com