Production method for a hot-melt film recycling air-bag scraps for shoes, and a hot-melt film produced using the method

A production method and technology of hot melt, applied in recycling technology, plastic recycling, application, etc., can solve the problem of not producing a three-layer structure hot melt film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

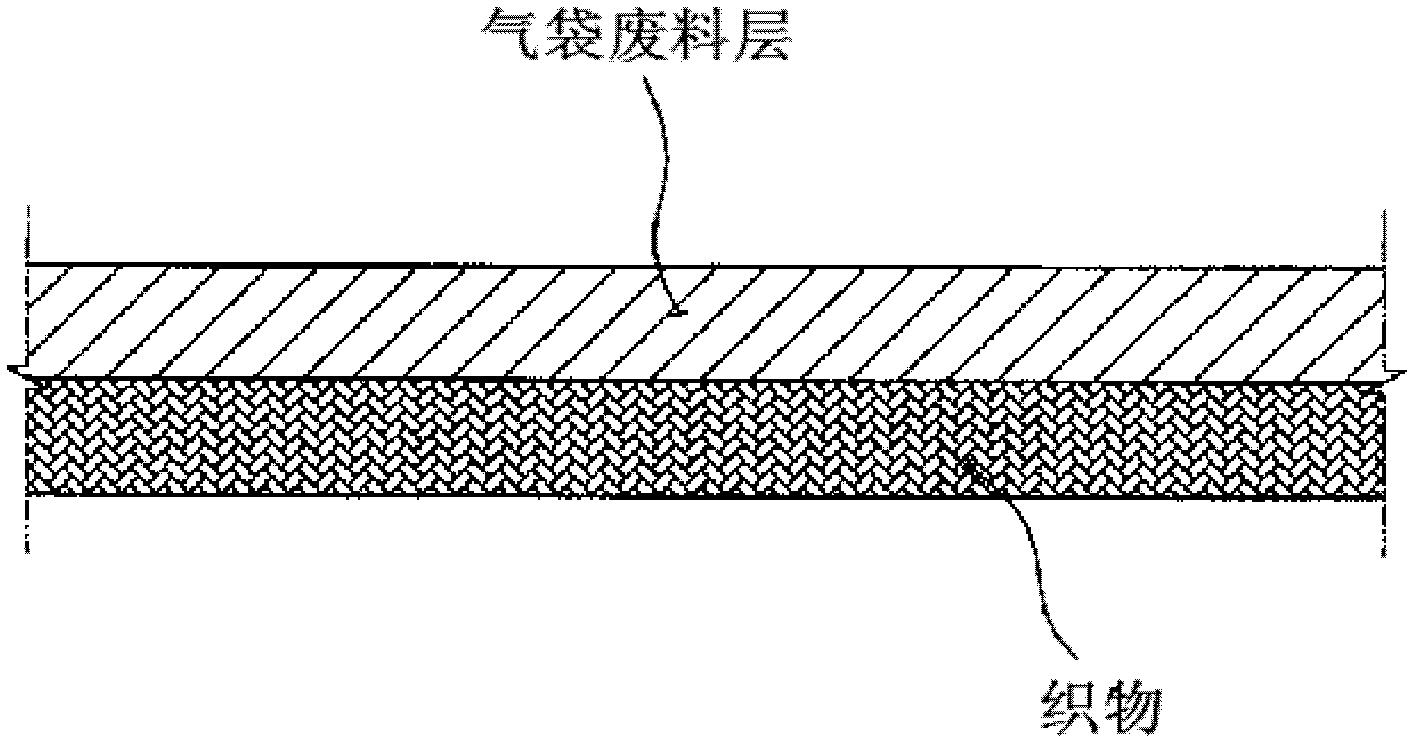

[0032] refer to figure 1 , describes in detail the production method of the hot melt film of the single-layer structure of the first preferred embodiment of the present invention, and the hot melt film is used as a label mark pasted on the shoe.

[0033]Typically, each shoe will have a separate label attached to the inside of the shoe to display various information, such as the size of the shoe, the country of manufacture, and so on. Such a label is called a size label, and the film used for the above purpose is called a label tag film. After the required information is printed on the surface of the membrane, this membrane is heat-fused and pasted on the surface of the fabric located inside the shoe. There is no example where recycled TPU is used as such a film, therefore, in the present invention, the properties of the air bag waste are adjusted so that the air bag waste has a form suitable for the application purpose.

[0034] To tailor the properties to suit the applicati...

specific Embodiment approach 2

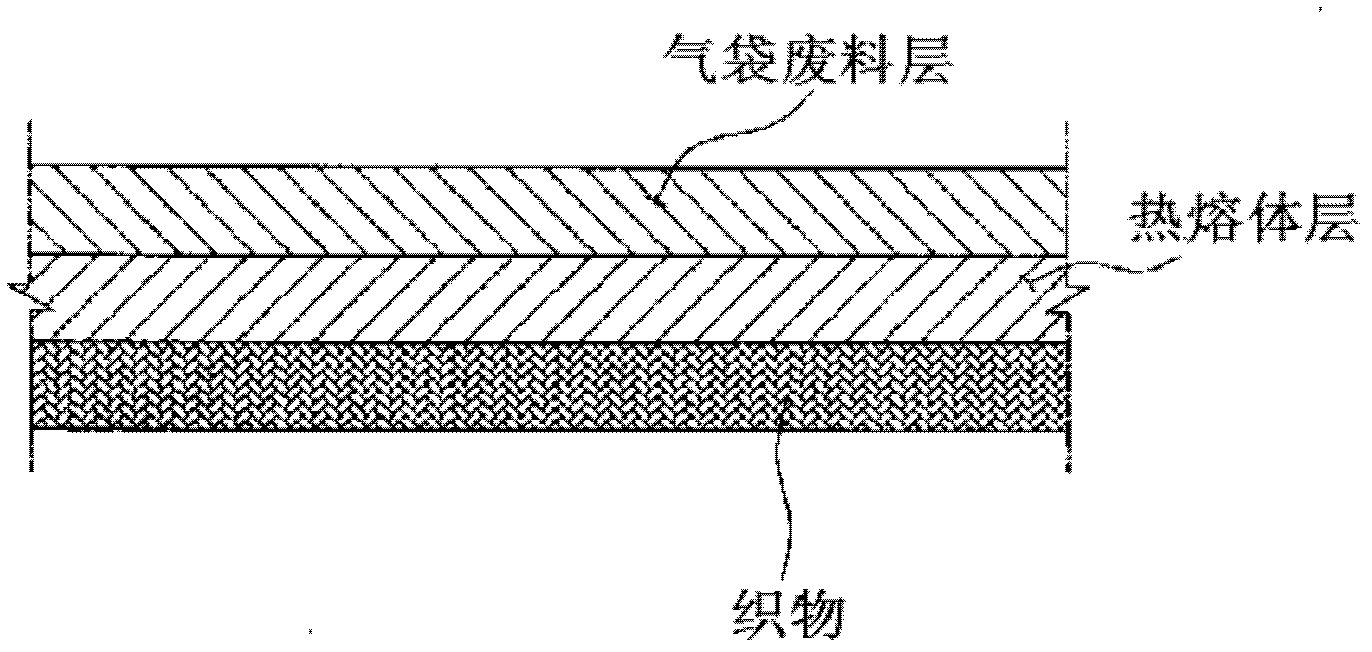

[0041] Such as figure 2 As shown, in the second preferred embodiment, the regenerated hot melt film having a double-layer structure has an air bag waste layer and a hot melt layer, which will be described in detail below.

[0042] The hot-melt film having a double-layer structure passes through a step of extruding a high-density TPU film on an upper layer, and simultaneously extrudes a hot melt on a lower layer by a co-extrusion method so as to provide a hot-melt property. In particular, a large amount of air bag waste is used as an upper layer of a hot-melt film without any attempt to enhance the environmental friendliness of the hot-melt film product until now. Table 3 shows the mixing ratios of the ingredients when producing the hot-melt film of the double-layer structure.

[0043] table 3

[0044]

[0045] In the hot melt mixing ratio of the lower layer (hot melt layer), the viscosity of the entire mixed resin is very important. Melt Flow Index (MI) - the most commo...

specific Embodiment approach 3

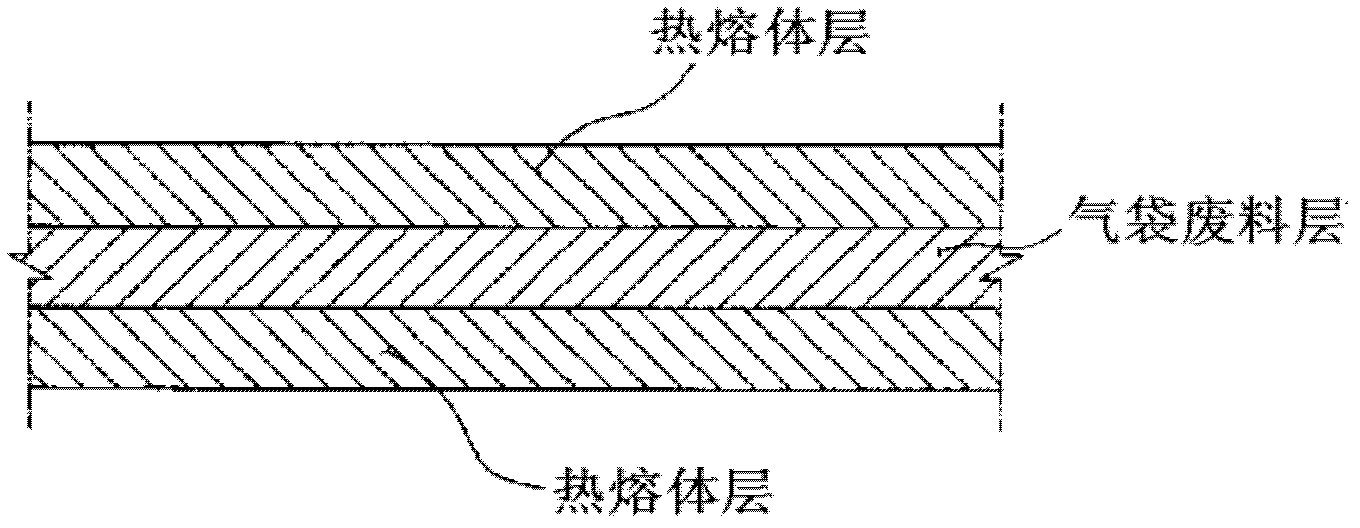

[0067] Such as Figures 3a to 3c As shown, in the third preferred embodiment, the hot melt film of the regenerated three-layer structure will be described in detail as follows. In the three-layer structure, the hot melt layer is arranged on the upper layer and the lower layer respectively, and the air bag A scrap layer or a TPU layer is arranged in the middle layer.

[0068] Conventional single-layer hot-melt films can cause problems when the two fabrics have different weaves. For example, when a low-density fabric and a high-density fabric are bonded together by a hot-melt method using a hot-melt film, the hot-melt melted by heating tends to attract the low-density fabric easily. Therefore, the hot melt concentrates on the fabric on one side, resulting in less adhesion.

[0069] In order to prevent the hot melt from concentrating on one side, such as Figure 3a with Figure 3b As shown, a hot-melt film with a double-layer structure was produced, with an air bag waste laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com