Biodegradable adhesive and preparation method thereof

A biodegradable, adhesive technology, applied in the directions of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problem of no obvious change in molecular weight, achieve simple and easy preparation methods, improve residual adhesive properties, and synthesize Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

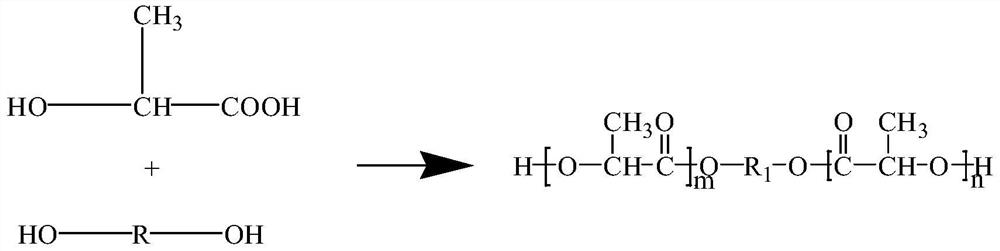

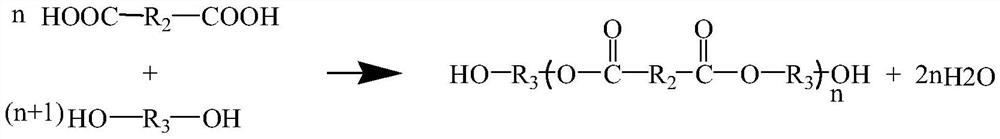

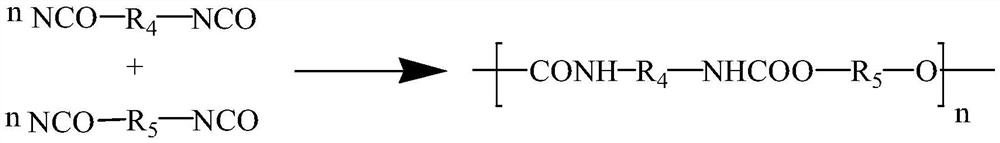

[0042] A biodegradable adhesive and a preparation method thereof, comprising the following steps:

[0043] Step 1: Under the action of a catalyst, carry out esterification and polycondensation reaction between lactic acid and its mixture and polyol compound at 140-220°C, and under the protection of nitrogen, evaporate most of the by-product water formed under normal pressure, and then Remove traces of water and excess polyol compounds under reduced pressure under vacuum until the acid value of the synthesized product is lower than 5mgKOH / g to obtain a polylactic acid copolymer polyol; the reaction time is 4-12h;

[0044] Step 2: Under the action of a catalyst, conduct esterification and polycondensation reactions between the polyacid compound and the polyol compound at 140-220°C, under the protection of nitrogen, evaporate most of the by-product water generated at normal pressure, and then vacuum Remove traces of water and excess polyol compounds under reduced pressure until t...

Embodiment 1

[0089] Step 1: 168.7g (1.5mol) mass concentration is 80% lactic acid, 15.2g (0.1mol) mass concentration is 50% glycolic acid, 10.4g (0.1mol) 3-hydroxybutyric acid, 6.8g (0.09mol ) 1,3-propanediol and 0.7g of stannous octoate were added to the reactor, and under the protection of nitrogen, the oil bath was heated to 170°C for 3 hours of reaction, then vacuumed, and the vacuum degree was gradually increased, and trace water and excess 1 , 3-propanediol, continue to react at 170°C for 2 hours to obtain a viscous polylactic acid copolymer polyol, and its molecular weight is 2178 according to GPC;

[0090] Step 2: 177g (1.5mol) of succinic acid, 120.8g (1.59mol) of 1,3-propanediol and 0.7g of stannous octoate were added to the reactor. Under the protection of nitrogen, the oil bath was heated to 175°C for 3 hours, and then pumped Vacuum, and gradually increase the vacuum degree, reduce the pressure to remove trace water and excess 1,3-propanediol, continue the reaction at 175 ° C f...

Embodiment 2

[0093] Step 1: 202.5g (1.8mol) mass concentration is 80% lactic acid, 15.2g (0.1mol) mass concentration is 50% glycolic acid, 31.2g (0.3mol) 3-hydroxybutyric acid, 6.8g (0.09mol) ) 1,3-propanediol, 4g polypropylene glycol 400 (0.01mol) and 0.8g stannous octoate were added to the reactor, and under the protection of nitrogen, the oil bath was heated to 180°C for 4 hours, and then vacuumed, and the vacuum degree was gradually increased. Remove traces of water and excess 1,3-propanediol under reduced pressure, and continue the reaction at 180°C for 3 hours to obtain a viscous polylactic acid copolymer polyol with a molecular weight of 2938 as measured by GPC;

[0094] Step 2: Add 118g (1mol) of succinic acid, 80.5g (1.06mol) of 1,3-propanediol and 0.6g of stannous octoate into the reactor. Vacuum, and gradually increase the degree of vacuum, decompress to remove traces of water and excess 1,3 propylene glycol, continue to react at 180°C for 2 hours, and obtain a viscous polyester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com