Agitator tool

a technology of agitator and tool, which is applied in the field of tools, can solve the problems of blockage of the pump ability, failure of the progressive cavity pump or other failure of the ability to produce fluid, and failure of the conventional pumping means, and achieve the effect of effective agitation of the production fluid, cost-effective production, and energized production fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

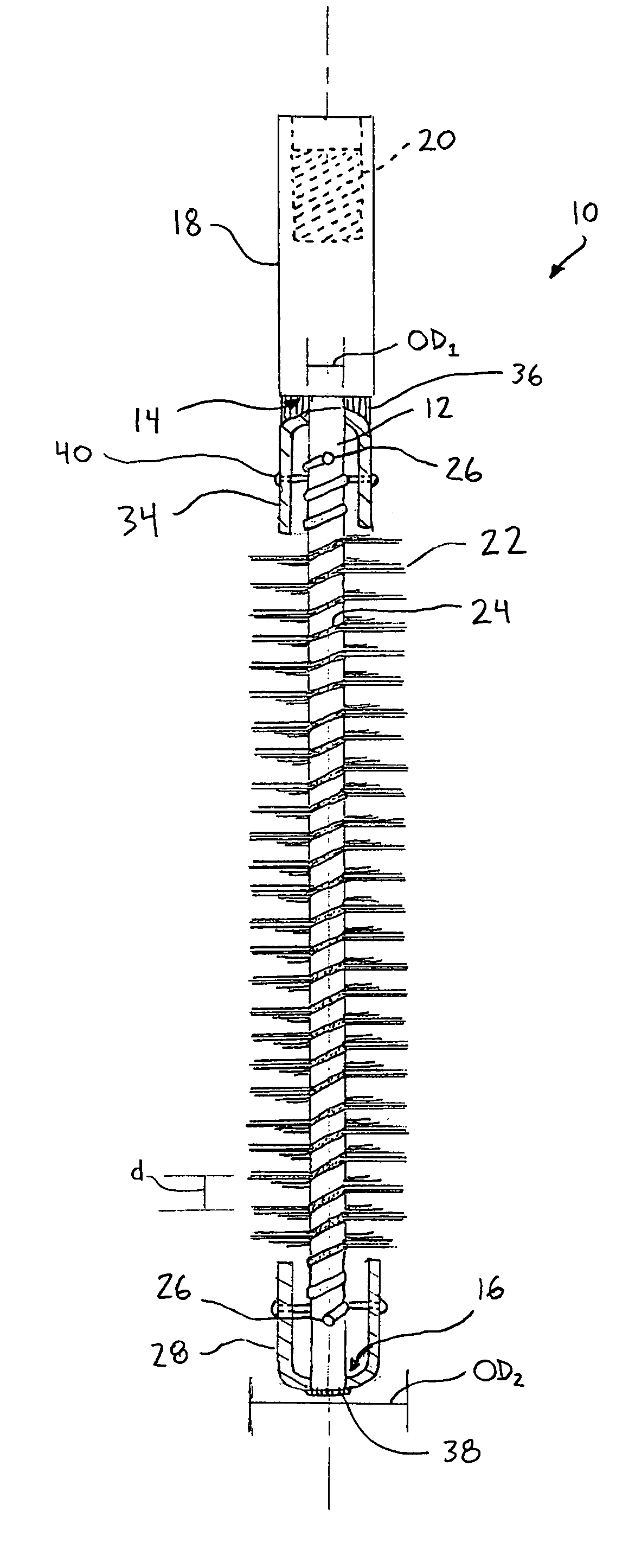

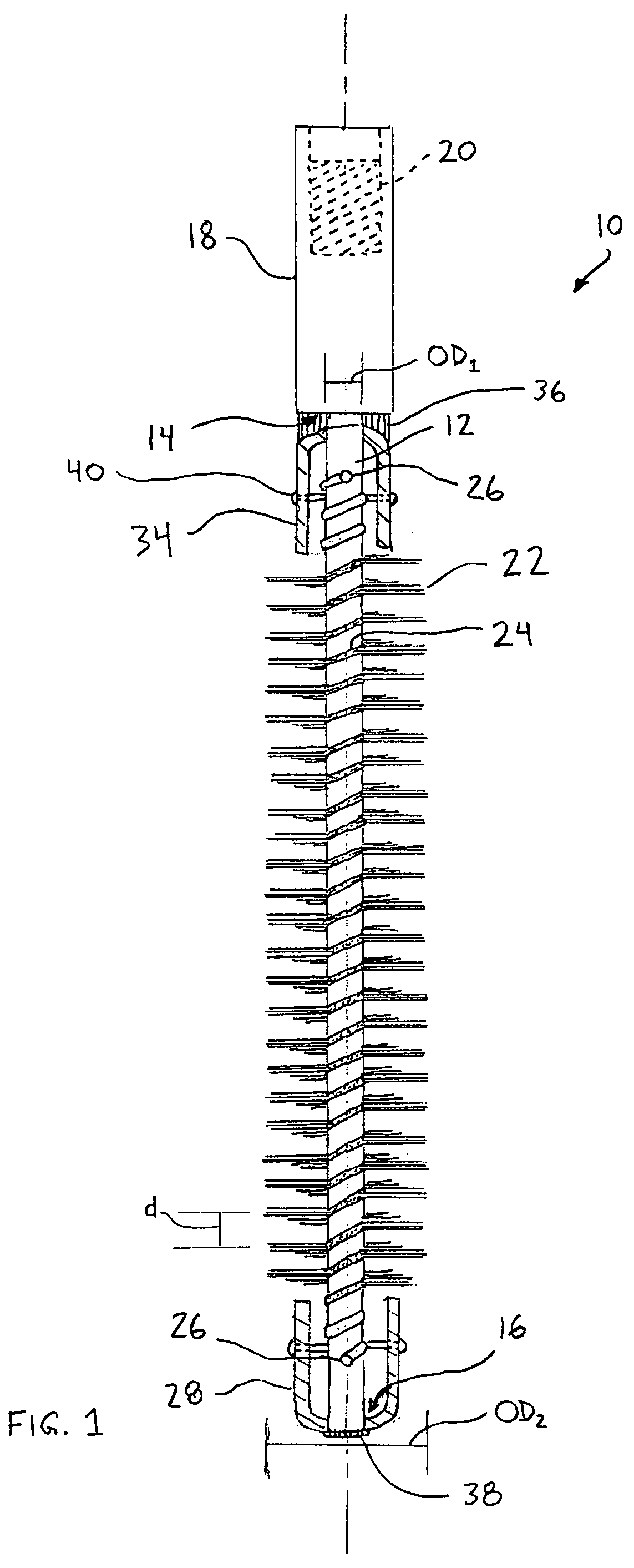

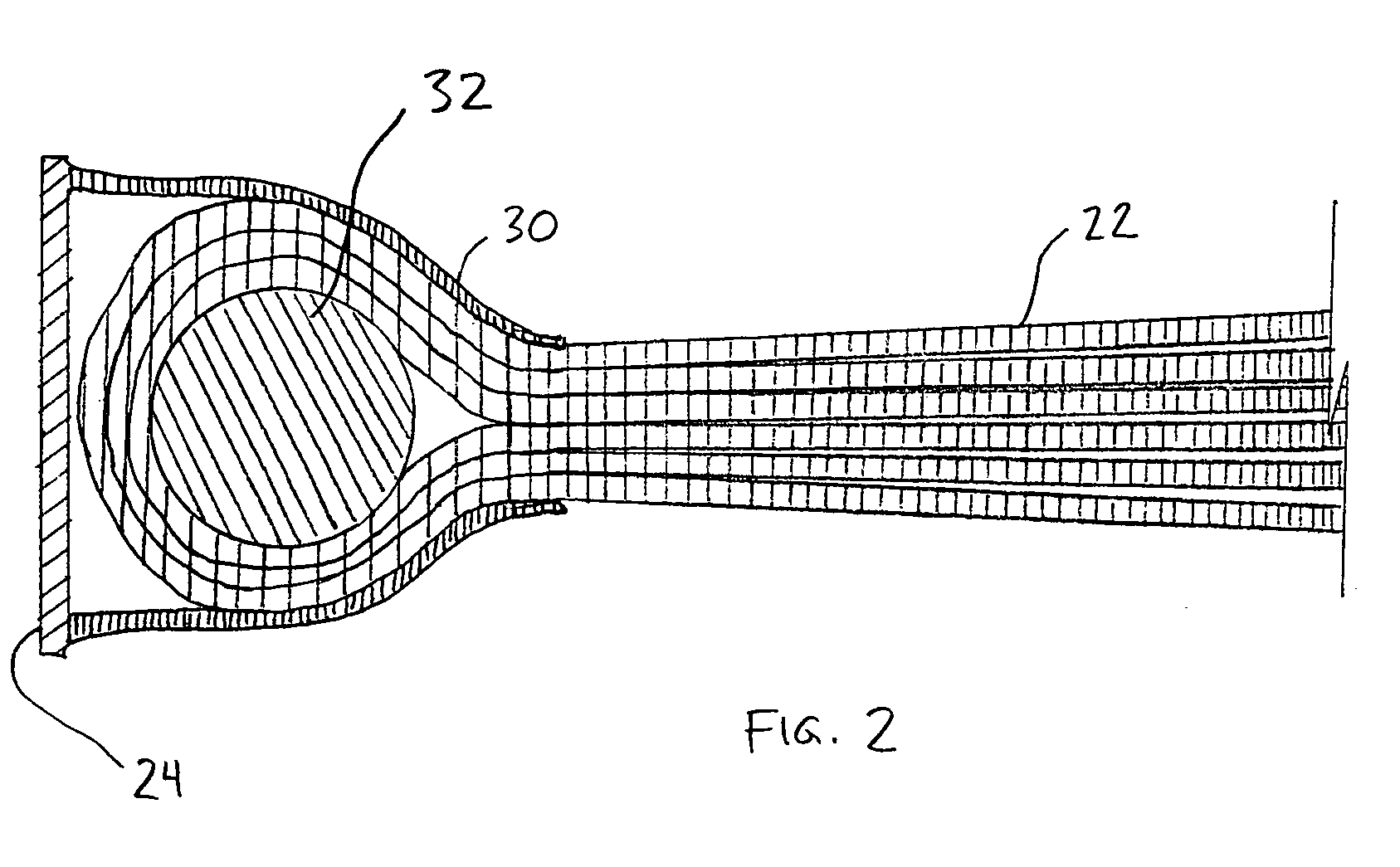

[0019] Referring now in detail to the accompanying drawings, there is illustrated an exemplary embodiment of the agitator tool according to the present invention, generally referred to by the numeral 10. The agitator tool 10, for use in surface flowlines or downhole casings (not shown), comprises an elongate shaft 12 having a downstream end 14 and an upstream end 16. The elongate shaft 12 is a 16″ 4140 steel shaft having an outer diameter OD1 of ½″. The length of the elongate shaft 12 depends on how much sump is required or desired in a given context, and the outer diameter OD1 and shaft geometry (for example, having a bend in the elongate shaft 12, or some other irregular form) can also be adjusted to address specific needs (the outer diameter OD1 will depend to a large degree on the stator / rotor dimensions). Other materials can also be used to manufacture the elongate shaft 12. The elongate shaft 12 is welded to a slim-hole coupling 18 at the downstream end 14, the slim-hole coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com