Lignin carbon nanofiber and preparation method thereof

A nano-carbon fiber and lignin technology, applied in the field of materials, can solve the problems of easy clogging, poor lignin fibrillation, complex spinneret structure, etc., and achieve the effect of not being easy to clog and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Lignin pretreatment: Weigh 10g of wheatgrass lignin and dissolve it in 200mL of water whose pH value is adjusted to 8 with NaOH. Filter the solution successively with the filter membrane, take fractions with a relative molecular mass between 5000 and 50000, adjust the pH value to 5 with hydrochloric acid, concentrate and dry, and then use 100 mL of lignin with a volume ratio of 2:1 to Dissolve the 2-dichloroethane-ethanol mixture, separate the insoluble matter, add the supernatant to diethyl ether to precipitate the lignin, centrifuge the precipitate and wash it 5 times with diethyl ether, dry it in vacuum, and pulverize it;

[0036] 2. Preparation of spinning solution: Add 5g of lignin obtained in step 1 into 25mL of dimethyl sulfoxide, stir to make it completely dissolve, and become a solution;

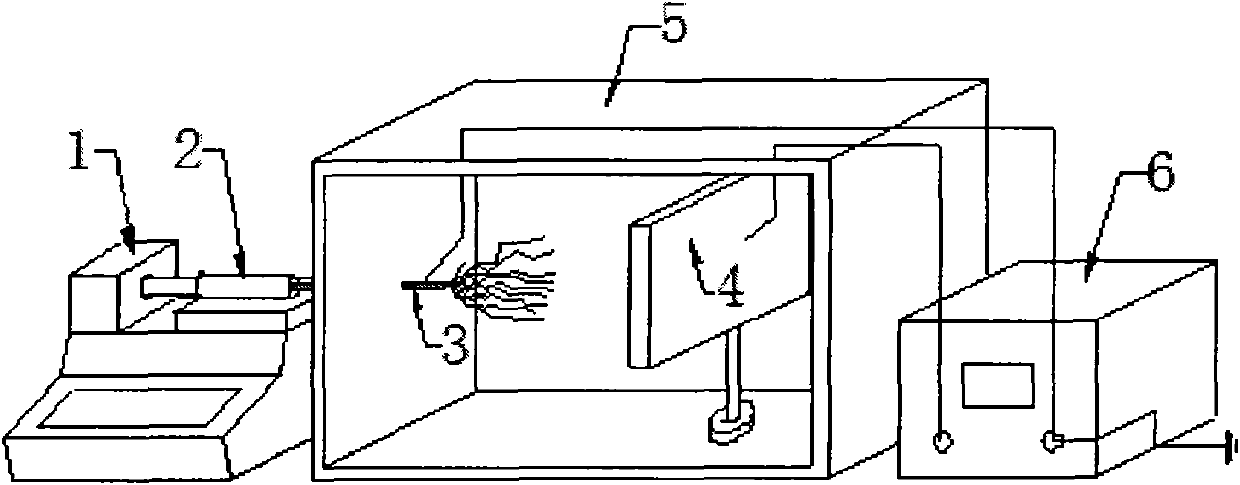

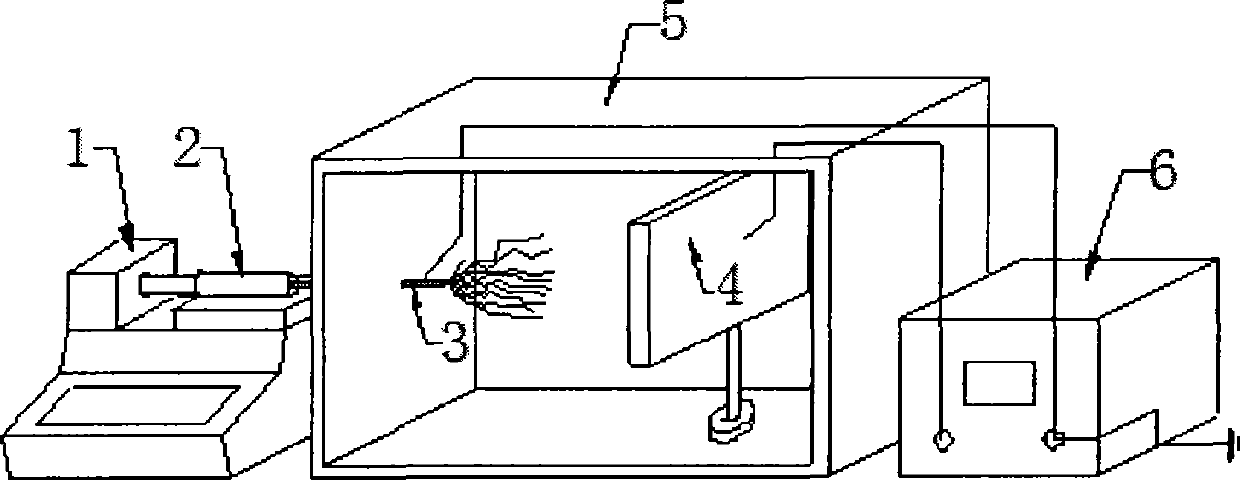

[0037] 3. Electrospinning: use as figure 1 In the high-voltage electrospinning device shown, the positive and negative poles are connected to the spinneret 3 and the coll...

Embodiment 2

[0041] 1. Lignin pretreatment: Weigh 10g of bagasse alkali lignin and dissolve it in 200mL of water whose pH value is adjusted to 12 with NaOH. Filter the solution successively with the filter membrane, take fractions with a relative molecular mass between 5,000 and 50,000, adjust the pH value to 7 with hydrochloric acid, concentrate and dry, and then use 200 mL of lignin with a volume ratio of 1:1 to Dissolve the 2-dichloroethane-ethanol mixture, separate the insoluble matter, add the supernatant to diethyl ether to precipitate the lignin, centrifuge the precipitate and wash it 4 times with diethyl ether, dry it in vacuum, and pulverize it;

[0042] 2. Preparation of spinning solution: add 5g of lignin obtained in step 1 to 100mL of N,N-dimethylformamide, stir to make it completely dissolve, and become a solution;

[0043] 3. Electrospinning: use as figure 1 In the high-voltage electrospinning device shown, the positive and negative poles are connected to the spinneret 3 and...

Embodiment 3

[0047] 1. Lignin pretreatment: Weigh 10g of masson pine base lignin and dissolve it in 200mL of water with NaOH to adjust the pH value to 9. Ultrafiltration membranes filter the solution in sequence, take fractions with a relative molecular mass between 5000 and 50000, adjust the pH value to 7 with sulfuric acid, concentrate and dry, and then use 1 with a volume ratio of 2:1 for the dried lignin, Dissolve the 2-dichloroethane-ethanol mixture, separate the insoluble matter, add the supernatant to diethyl ether to precipitate lignin, centrifuge the precipitate and wash it 3 times with diethyl ether, dry it in vacuum, and pulverize it;

[0048] 2. Preparation of spinning solution: add 5g of lignin obtained in step 1 to 100mL of 1,4-dioxane, stir to make it completely dissolve, and become a solution;

[0049] 3. Electrospinning: use as figure 1 In the high-voltage electrospinning device shown, the positive and negative poles are connected to the spinneret 3 and the collecting pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com