Tobacco charging process

A process and tobacco technology, applied in the field of tobacco feeding process, can solve the problems of increased process material loss, long process flow, insufficient uniformity of feeding, etc., and achieve the effect of saving feeding cost, shortening process flow, and good feeding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

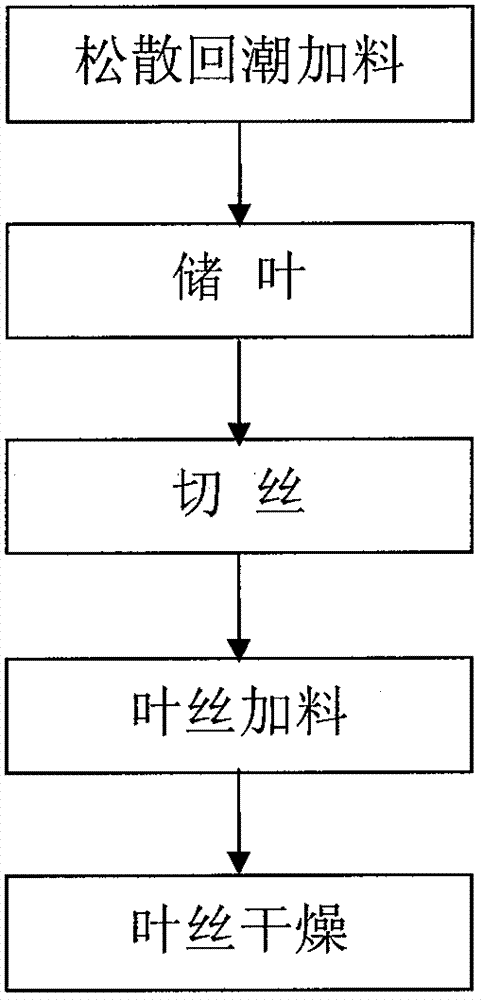

[0012] Specific examples are given below in conjunction with the accompanying drawings to further illustrate how a tobacco feeding process of the present invention is realized.

[0013] Such as figure 1 Shown, a kind of tobacco feeding process of the present invention comprises following processing steps:

[0014] (1) processing the cigarette block into a loose re-moisture feeding process of applying a feed liquid to the loose tobacco sheet;

[0015] The described loose moisture resurgence feeding process is to send the tobacco sheets into the loose moisture resurgence feeding equipment, apply the feed liquid, and use steam to increase the temperature and moisture content to make uniformly fed blades. The process parameter level range: the outlet temperature of the tobacco sheet is 55 ℃~75℃, moisture content 17.0%~22.0%.

[0016] (2) The leaf storage process that makes the tobacco sheet fully absorb the feed liquid;

[0017] The leaf storage process is to send the loosely f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com