Bridge structure intelligent reinforcing assembly and fiber grating sensor combining and bonding method

A technology of fiber grating and reinforcement components, which is applied in the direction of force measurement, instrument, measurement force, etc. by measuring the change of optical properties of materials when they are stressed, which can solve the problem of decreased accuracy of fiber grating sensors, reduction of carbon fiber volume content, and fiber hopping. Wire tension and shear failure, etc., to achieve the effects of long-term health monitoring, high material utilization, and large tension control stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

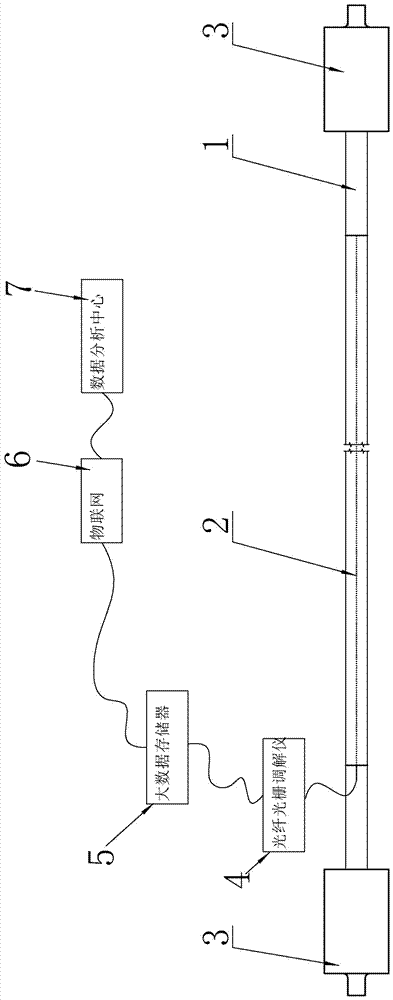

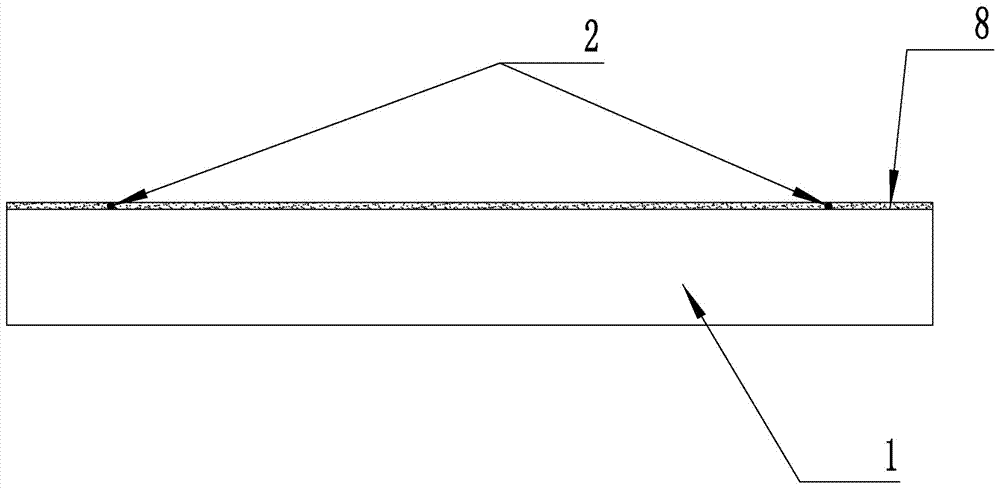

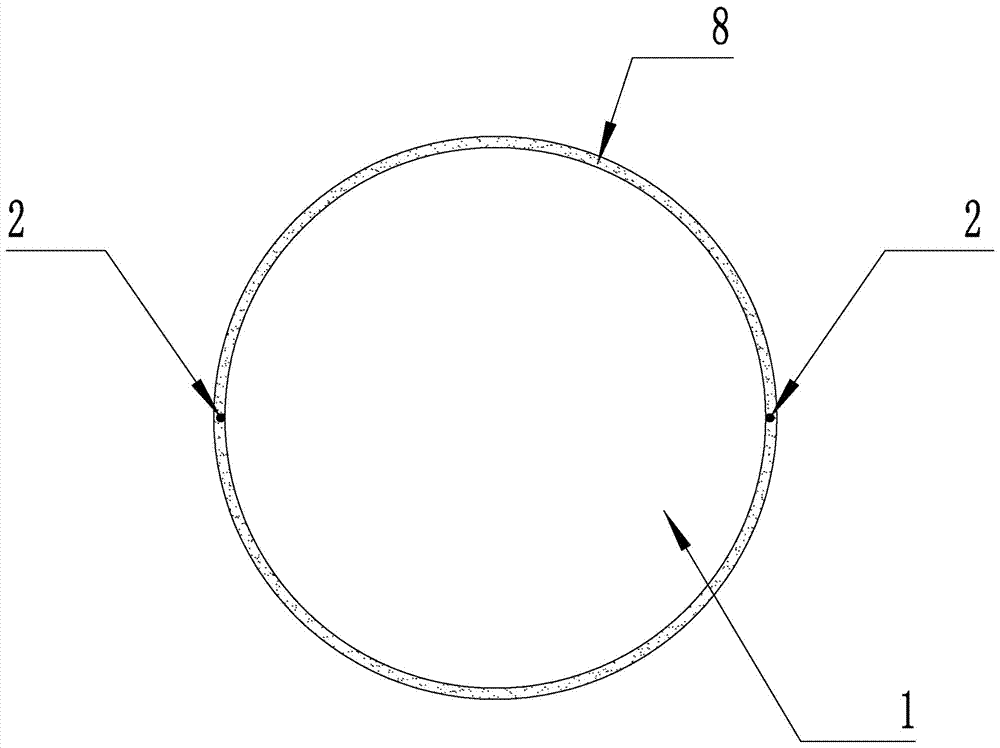

[0030] like figure 1 As shown, the stressed reinforcement of the bridge intelligent structure reinforcement assembly proposed by the present invention adopts carbon fiber reinforcement 1, and the fiber grating sensor 2 is laid on the The surface of the carbon fiber reinforcement 1 is bonded together with the carbon fiber reinforcement 1 through the covering part. The anchor structure 3 will fix the two ends of the carbon fiber reinforcement 1 to the beam body, the fiber grating mediator 4 is connected to the fiber grating sensor 2, and the memory 5 with ultra-high storage capacity (also called a big data memory) will receive and store each The data of the stressed use state of the carbon fiber reinforcement 1 collected by the fiber grating mediator, and then the data analysis center 6 obtains the data of the stressed use state of the carbon fiber reinforcement 1 from the memory through the Internet of Things 7 and analyzes it, so that both the installation site The data quant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com