Patents

Literature

50results about How to "Fiber soft" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing terylene fibre with pearly lustre

InactiveCN101381903AImprove performanceAdd lessFilament/thread formingPigment addition to spinning solutionPolyesterLight extinction

The invention relates to a method for preparing polyester fibers with pearly luster. The method comprises the following steps: (1) pearlescent pigment agglomerate and full-dull PET fiber forming resin slice are blended according to the weight ratio of 5-20 to 80-95; and after drying, the water content is less than 100PPM, and the slice is delivered to a feeding port of an extruder and enters an screw extruder for heat fusing and compression; (2) the temperature is controlled to between 290 and 305 DEG C, fusant extruded out by the rotary screw rod enters a metering pump through a distributing pipe and a static mixer, delivered to a spinning component, filtered by a sea sand layer and pressed into a spinning plate to form fusant current which is cooed to form in a spinning cabinet, and the surface of a filament bundle is covered by a spinning finish; and 3. the spinning speed pre-extension is between 2, 500 and 3, 500m / min, the winding carry rate is between 5 and 15 percent for wind-forming, and the full-dull pearlescent polyester fiber POY is obtained. The manufacturing process is easily realized, and is convenient to improve the pearlescent fiber spinning effect and simultaneously provides the fibers with light extinction performance, and the pearlescent pigment has excellent performance and little feed rate.

Owner:DONGHUA UNIV

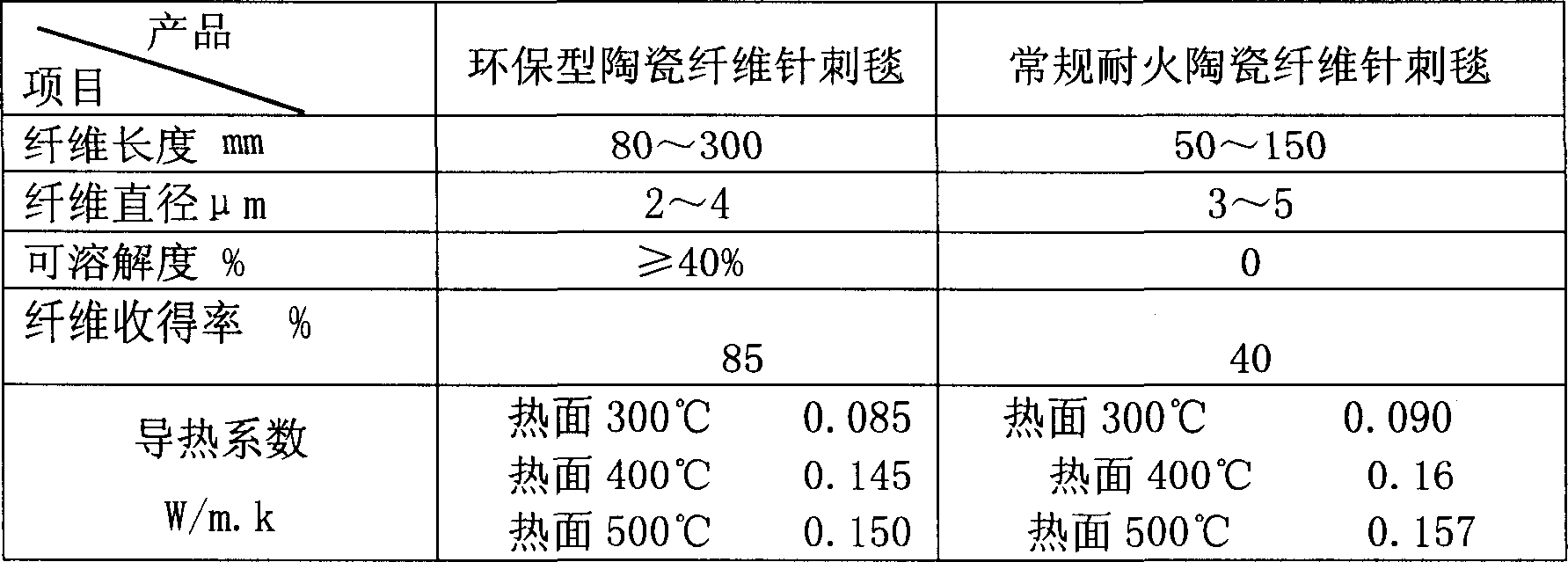

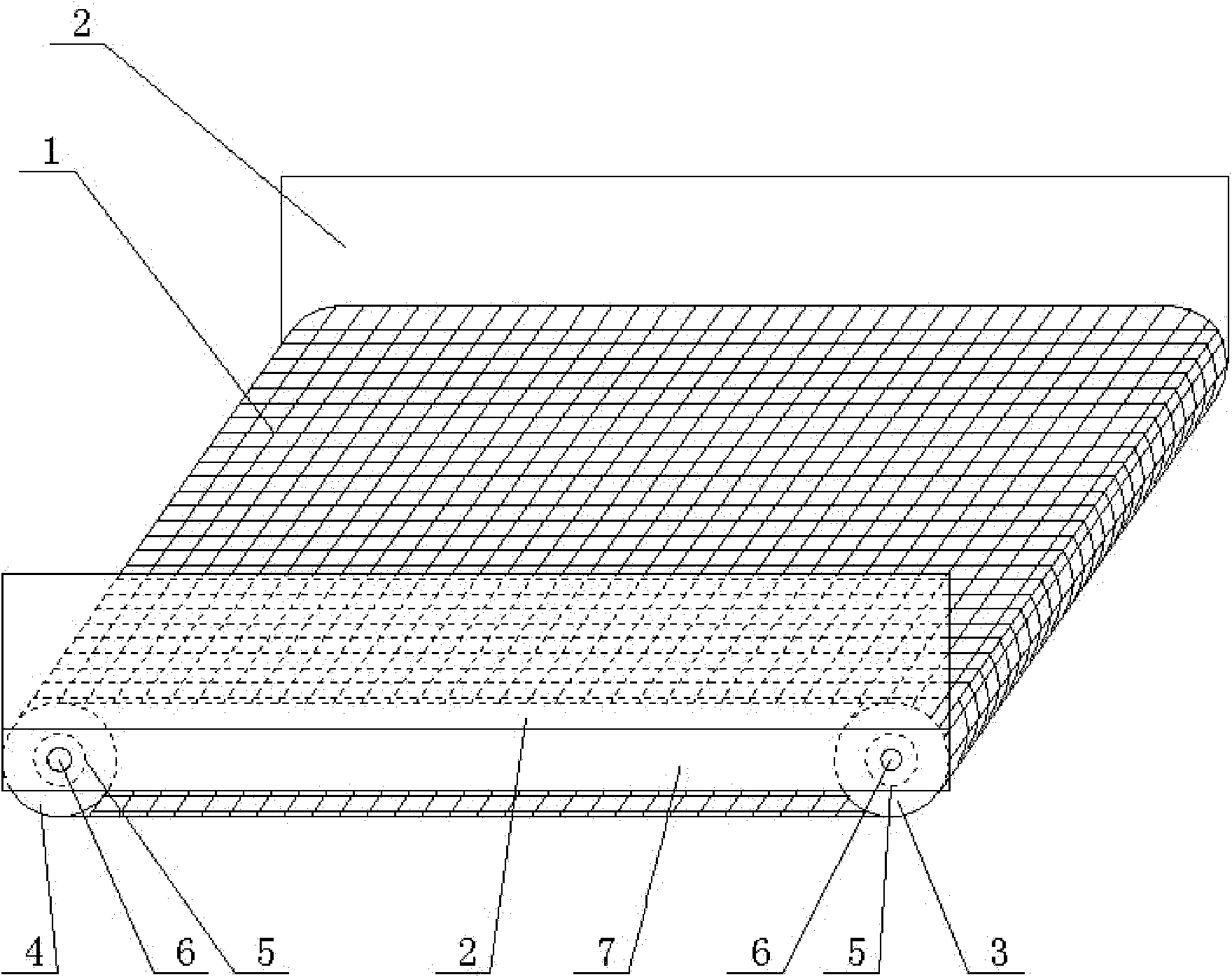

Environment protection type ceramic fibre needling blanket

The present invention belongs to a refractory heat-insulating material, and relates to an environment-protecting ceramic fibre needle-punched carpet and its preparation method. Its raw material silicon dioxide and aluminium oxide are undergone the processes of melting and fibre formation to obtain ceramic fibre, said ceramic fibre is undergone the processes of collecting, needling, heat treatmentand cutting so as to obtain the invented ceramic fibre needle-punched carpet. It is characterized by that its composition also contains 4-6 portions of magnesium oxide and / or calcium oxide, and its fibre-forming process adopts the blowing or centrifugal spinning process. Said fibre is stable in quality and high in yield rate.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Licorice root chewing gum, and prepn. method therefor

A chewing gum is prepared from the block, fibers of particles of liquorice root, coating or filler, functional material, and additive. Its preparing process is also disclosed. It features that its dreg can be easily removed from ground.

Owner:陈光

Anti-ultraviolet antibacterial aloe fiber fabric and preparation method thereof

ActiveCN103966694AHas the effect of promoting blood circulationPromote blood circulationConjugated cellulose/protein artificial filamentsArtifical filament manufacturePolymer scienceVitamin C

The invention discloses an anti-ultraviolet antibacterial aloe fiber fabric. The anti-ultraviolet antibacterial aloe fiber fabric is prepared from the following raw materials in parts by weight: 12-14 parts of plastic starch, 70-80 parts of aloe fiber, 70-80 parts of 1-ethyl-3-methylimidazolium acetate, 40-50 parts of 1-ethyl-3-methylimidazolium chloride, 1-2 parts of nano calcium carbonate, 8-12 parts of Chinese yew fiber, 5-7 parts of virgin silk, 0.3-0.5 part of vitamin C, 3-5 parts of titanium dioxide, 2-4 parts of aloe liquid, 3-5 parts of safflower, and 0.4-0.6 part of a spinning auxiliary. The anti-ultraviolet antibacterial aloe fiber fabric is good in moisture permeability, has the disease-resistant function, has good antibacterial and antiphlogistic effect through the addition of aloe liquid, is high in fiber strength through the addition of nano calcium carbonate, has uvioresistant efficacy thereby being helpful to sunscreen and skin protection, and has the function of promoting blood circulation through the addition of safflower; spinning auxiliary is antistatic and is good in lubrication effect; the manufactured yarn does not break easily, and the fiber is flexible and elastic.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Staple fibre and filament of microcapsule-type aloe blending regenerated cellulose fibre and preparation method thereof

ActiveCN102691132AGood hygroscopicityFiber softConjugated cellulose/protein artificial filamentsRegenerated celluloseFilament yarn

The invention discloses a staple fibre and a filament of a microcapsule-type aloe blending regenerated cellulose fibre and preparation methods thereof. The invention comprises the following technical steps: (1) preparing a nanometer level aloe micropowder; (2) preparing an aloe liquid powder; (3) preparing an aloe spinning stock solution; (4) mixing the aloe spinning stock solution and the cellulose fiber stock solution, stirring uniformly and deaerating for 3-5 h; (5) filtering and spinning to obtain the aloe blending cellulose fiber. The aloe blending regenerated cellulose fibre prepared by the invention has characteristics of chemical and physical properties similar to cotton, good hygroscopicity, moisture releasability, soft and slipper fiber and silk-like luster; and fabric processed from the fiber is quite comfortable for wearing.

Owner:湖州珠力纳米材料科技开发有限公司

Laundry liquid and preparation method thereof

ActiveCN101906356AAvoid the disadvantagesStrong cleaning and decontamination abilityAmpholytes/electroneutral surface-active compoundsDetergent compounding agentsChemistryTextile fiber

The invention discloses laundry liquid and a preparation method thereof. Mild surfactants with mild washing property, high decontamination capacity, no pollution on the environment, such as fatty alcohol-polyoxyethylene ether (AEO9), dodecyl dimethylaminoacetate (BS-12), dodecyl dimethyl benzyl ammonium chloride (1227), distearyl dimethyl ammonium chloride (D1821), polyethylene glycol 6000DS diester, coconut oil diethanolamine (6501) and the like are prepared into the laundry liquid according to a certain proportion and a process; clothes washed by the laundry liquid have soft textile fibers and comfortable wear; and the laundry liquid is mainly used for washing personal clothes, sheets and bedding bags of households, sheets and bedding bags of hotels and the like.

Owner:JIANGSU AITEFU 84

Preparation method of long raw bamboo fiber

ActiveCN107937993AAchieve softeningEasy to soakMechanical fibre separationFibre treatment to obtain bast fibreChemical treatmentWastewater

The invention discloses a preparation method of long raw bamboo fiber, which belongs to the technical field of vegetable fiber production, and solves the problems of low production efficiency, low yield and serious waste water pollution of the current preparation methods. The method comprises the following steps: bamboo wood slicing, high-temperature high-pressure treatment, tearing processing, enzyme processing, chemical treatment, drying, and carding processing. The obtained long raw bamboo fiber has the following characteristics that an average fiber length is 4-5 cm, fineness is no less than 100 Nm, and the yield is no less than 60%. In addition, the long raw bamboo fiber has the beneficial effects that high production efficiency (annual output of a production line is no less than 50,000 tons), waste water pollution is light, and fiber is soft.

Owner:FUJIAN AGRI & FORESTRY UNIV

Ramee degumming process

InactiveCN101012575AEasy to separateLoose separationFibre treatment to obtain bast fibreOxalateBoiling process

The invention relates to a degumming technology for ramie, comprising unpacking and untying braches, loading cage, boiling, softening, bleaching and washing by acid, supplying oil, deoiling and drying. The boiling process is that the original fiber is put into the mixed solution, of which the weight is nine to twelve times of the weight of original fiber; the pressure is maintained in 0.1-0.2MPa and the maintaining time is for 1-1.5 hours. The mixed solution comprises sodium hydroxide, oxidant, oxalate and scouring agent. Thereinto, the content of sodium hydroxide is 5-8g / l, the content of oxidant is 5-10g / l, the content of oxalate is 3-8g / l and the content of scouring agent is 3-5g / l. By adopting the degumming technology for ramie, the scouring time for ramie is decreased, the manufacturing efficiency is improved, the circumstance pollution is decreased and the quality of ramie after degumming is improved.

Owner:CHONGQING FULING KINGLONG

Wood and bamboo fiber mercerizing pulp and preparation method thereof

InactiveCN102121205AImprove breathabilityGood flexibilityNatural cellulose pulp/paperCellulose material pulpingFiberFree state

The invention relates to a wood and bamboo fiber mercerizing pulp and a preparation method thereof. The fiber mercerizing pulp is prepared through the following steps: swelling, mercerizing, neutralizing, washing, concentrating, drying a wood pulp or bamboo pulp which is utilized as a raw material in a free state of the fiber without a pressing or clamping state, wherein the obtained mercerized fiber is natural in flexibility. The mercerizing pulp obtained in the invention is good in air permeability, good in intensity, large in fiber length, high in yield and low in cost; and the cotton fiber is saved.

Owner:张金

Core-skin type paper making modeling net filament

InactiveCN101161874AFiber softExtended service lifeFilament/thread formingMachine wet endPolyethylene terephthalatePolytrimethylene terephthalate

The present invention discloses a sheath-core papermaking molding net monofilament, which is sheath-core fiber, wherein, a core layer is polytrimethylene terephthalate or polybutylene terephthalate; a skin layer is polyethylene terephthalate. The present invention is soft in fiber, can prolong the life-span of a molding net by more than 20 percent when compared with the prior common molding net fiber, and is good in the size stability of fiber.

Owner:DONGHUA UNIV

Compound crystal variation modification method of ramie fiber

InactiveCN103437151ALarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsMicrowaveCentrifugation

The invention relates to a compound crystal variation modification method of ramie fiber. The compound crystal variation modification method comprises following steps: the ramie fiber is delivered into a sealed container; a modification medium is added; the pressure of the sealed container is increased to be as large as a modification pressure, and then is decreased instantaneously; the ramie fiber is subjected to vacuumization, high speed centrifugation spinning drafting and microwave radiation; and the modification medium is removed so as to obtain the compound crystal variation modified ramie fiber.

Owner:DONGHUA UNIV +1

Superfine full-dull sheath-core fiber

InactiveCN101760804AFiber softFiber fluffyFilament/thread formingConjugated synthetic polymer artificial filamentsFiberPolyester

The invention provides superfine full-dull sheath-core fiber which is prepared through the following steps: firstly, adding nano-grade silica and pearl powder as dulling agent to chemical fiber polyester; spinning the blended chemical fiber polyester, nano-grade zinc oxide and water-soluble polyester by a spinneret plate at the same time, wherein the cross section of the silk thread takes the shape of an ocean island, i.e., the chemical fiber polyester, the nano-grade zinc oxide is at the center of each island, and the water-soluble polyester constitutes the ocean; and then, dissolving the water-soluble polyester to obtain the superfine full-dull sheath-core fiber.

Owner:SUZHOU SHUANGLUN CHEM FIBER

Crystal lattice change modification method of ramie fiber

InactiveCN103437097ALarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsCrystal structureCrystallinity

The invention relates to a crystal lattice change modification method of ramie fiber. The method is characterized in that the ramie fiber is placed in a sealed container, modifying media are filled, the pressure is boosted to the modification pressure, then, the pressure is instantaneously released, the modifying media are removed, and the ramie fiber modified crystal lattice change is obtained. Through adopting the technical scheme, the crystal change modification method has the following advantages that 1, the modification goal is reached through changing the crystal lattice structure, the modified fiber overcomes the original defects, the pores are enlarged, the crystallinity degree is reduced, the fiber is soft, and the size stability, the softness and the dyeing performance of products are improved; 2, the method of instantaneously releasing the pressure is adopted, the modified fiber expands to the greatest degree, and the bulkiness and the softness of the fiber are greatly improved, so the spinning, weaving and dyeing performance of the fiber is greatly improved.

Owner:DONGHUA UNIV +1

Ultrahigh molecular weight polyethylene fiber and preparation method thereof

ActiveCN106757467AReduce coefficient of frictionLow filling speedArtificial filament washing/dryingArtificial filament heat treatmentFiberAntistatic agent

The invention discloses a preparation method of an ultrahigh molecular weight polyethylene fiber. The preparation method comprises the following steps: (1) preparing ultrahigh molecular weight polyethylene frozen collagen fibril by a gel-spinning method; (2) balancing and standing the frozen collagen fibril; (3) pre-drafting, extracting, drying and performing thermal-drafting not lower than level III in sequence on the balanced and stood frozen collagen fibril, and making the ultrahigh molecular weight polyethylene frozen collagen fibril pass through a coating roller carrying an anti-static agent aqueous solution while thermal-drafting is performed; (4) drying to obtain the ultrahigh molecular weight polyethylene fiber. By adopting the preparation method of the ultrahigh molecular weight polyethylene fiber, the strength and modulus are enhanced, and the problem of influence on post-machining since the fiber is electrified is solved; the ultrahigh molecular weight polyethylene fiber has low static electricity.

Owner:SURREY HI TECH INC

Production method of polyester profiled fiber plated with indium tin oxide

InactiveCN102828286ASimple production equipmentShort processVacuum evaporation coatingFilament/thread formingPolyesterFiber

The invention discloses a production method of polyester profiled fiber plated with indium tin oxide, comprising the following steps of: carrying out magnetron sputtering coating on a polyester film, plating indium tin oxide on two faces of the film, carrying out micro-cutting on the plated film, and carrying out winding shaping so as to prepare the polyester fiber plated with indium tin oxide. The thickness of the indium tin oxide thin layer is 10-500 nm. The micro-cutting width of the film is 0.1-1.0 mm. The thickness of the used film is 5-50 microns.

Owner:樊健美

Crystal lattice change modification method for viscose fiber

InactiveCN103437098ALarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsPorosityCrystal structure

The invention relates to a crystal lattice change modification method for a viscose fiber. The crystal lattice change modification method comprises the following steps of placing the viscose fiber in a closed container; filling a modifying medium into the closed container; boosting the closed container to a modifying pressure and then instantaneously releasing the pressure; removing the modifying medium to obtain a crystalloblast modified viscose fiber. The invention adopting the technical scheme has the advantages that firstly, the aim of modifying is achieved by changing a crystal lattice structure, the modified fiber overcomes original defects, is increased in porosity, reduced in crystallinity degree and is soft, and the dimensional stability, the softness, dyeing performances and the like of products are improved; secondly, by adopting a method of instantaneously releasing the pressure, the modified fiber expands to the maximum degree and the bulkiness and the softness of the fiber are greatly improved, and thus the spinning, weaving and dyeing performances of the fiber are greatly improved.

Owner:DONGHUA UNIV +1

Crystal variation modification method

InactiveCN103437149AWide range of applicationsImproved dimensional stabilityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsNatural fiberViscose fiber

The invention relates to a crystal variation modification method, and especially relates to a crystal variation modification method for textile materials. The crystal variation modification method comprises following steps: material to be modified is delivered into a sealed container; a modification medium is added; the pressure of the sealed container is increased to be as large as a modification pressure, and then is decreased instantaneously; and the modification medium is removed, and then the crystal variation modified material is obtained. Advantages of the crystal variation modification method are that: 1) application range is wide, the crystal variation modification method can be used for modification of natural fibers such as cotton fiber and all kinds of bast fibers, and also for modification of viscose fiber; 2) the material is modified by change of crystal lattice shape, original defects of the material are eliminated, pores are enlarged, crystallinity is reduced, fibers are softened, and dimensional stability, softness and dyeing properties of the obtained products are improved; 3) instantaneous pressure release is employed, so that the modified fiber expands to a highest degree, bulkiness and softness of the fiber are increased greatly, and spinning, weaving and dyeing performances of the fiber are improved significantly.

Owner:DONGHUA UNIV +1

Crystal variation modification method of ambari fiber

InactiveCN103437152BLarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsFiberOptoelectronics

Owner:DONGHUA UNIV +1

Hatched chicken feed additive capable of improving disease resistance

InactiveCN106071290AIncrease appetitePromote secretionAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention discloses a hatched chicken feed additive capable of improving disease resistance. The feed additive is prepared from the following raw materials in parts by weight: 10-13 parts of caraway, 5-6 parts of fresh fennel, 30-35 parts of soybeans, 10-13 parts of green bean starch, 7-9 parts of Chinese prickly ash, 20-25 parts of apricot kernels, 30-35 parts of polished glutinous rice, 40-50 parts of asparagus, 15-20 parts of fresh peach leaves, 3-4 parts of white vinegar, 4-5 parts of Baijiu, 5-6 parts of white sugar, an appropriate amount of ethyl maltol, an appropriate quantity of lactic acid bacteria and an appropriate amount of water. The feed additive disclosed by the invention is scientific in formula, can improve the immunity and the diseases resistance of hatched chickens and promote quick growth of chicks, is free from hormones, and facilitates human health.

Owner:HUAINAN SONGWANG HIGH QUALITY GRAIN PLANTING FARMERS SPECIALIZED COOPERAIVE

Incubated chicken feed additive capable of increasing feed conversion rate

InactiveCN105941992AIncrease appetitePromote secretionAnimal feeding stuffAccessory food factorsBiotechnologyDisease

The invention discloses an incubated chicken feed additive capable of increasing the feed conversion rate. The feed additive is prepared from, by weight, 4-5 parts of phoenix tree flowers, 8-10 parts of sticky rice, 20-25 parts of lotus roots, 15-20 parts of ruccola salad, 7-9 parts of peppers, 20-25 parts of apricot kernels, 30-35 parts of sticky rice, 40-50 parts of asparagus, 15-20 parts of fresh peach leaves, 3-4 parts of white vinegar, 4-5 parts of baijiu, 5-6 parts of white sugar, an appropriate amount of ethyl maltol, an appropriate quantity of lactic acid bacteria and an appropriate amount of water. The feed additive can increase the feed conversion and utilization rate, improve the immunity and prevent diseases of a respiratory system and a digestive system and is high in chicken survival rate and development speed.

Owner:HUAINAN SONGWANG HIGH QUALITY GRAIN PLANTING FARMERS SPECIALIZED COOPERAIVE

A kind of compound crystal transformation modification method of cotton fiber

InactiveCN103422274BLarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsMicrowaveCotton fibre

The invention relates to a composite crystal change modification method of cotton fiber. According to the method, the cotton fiber is placed in a closed container, a modification medium is added, pressure is raised to modification pressure, then, the pressure is released instantly, the combined effect of vacuumization, high-speed centrifugal rotation and drafting and microwave is used for removing the modified medium, and therefore composite crystal change and modified cotton fiber can be obtained. According to the crystal change and modified cotton fiber, pores are increased, degree of crystallinity is reduced, the fiber is soft, and size stability, flexibility, dyeing performance and the like of products are improved; the method of pressure instant release is adopted, and the fluffiness and flexibility of the fiber are improved greatly; the combined effect of vacuumization, high-speed centrifugal rotation and drafting and microwave is adopted, therefore, fiber quality is further improved, and modification efficiency is greatly improved.

Owner:DONGHUA UNIV +1

A kind of ultra-high molecular weight polyethylene fiber and its preparation method

ActiveCN106757467BReduce coefficient of frictionLow filling speedArtificial filament washing/dryingArtificial filament heat treatmentFiberPolymer science

The invention discloses a preparation method of ultra-high molecular weight polyethylene fibers, which comprises the following steps: (1) preparing ultra-high molecular weight polyethylene jelly filaments by using a gel spinning method; (3) Pre-stretch, extract, dry and carry out no less than three-stage hot-drawing of the jelly collagen filaments after the equilibrium static treatment, and while hot-drawing, make ultra-high-molecular-weight polyethylene The jelly collagen filaments pass through a coating roller with an antistatic agent aqueous solution; (4) drying to obtain ultra-high molecular weight polyethylene fibers. The ultra-high molecular weight polyethylene fiber prepared by the method of the invention not only improves high strength and high modulus, but also solves the problem that the post-processing of the fiber is affected by charging, and has low static electricity.

Owner:SURREY HI TECH INC

Ramie Degumming Process by Air Explosion at High Temperature

InactiveCN106637430BShort high temperature gas explosion timeIncrease productivityVegetable materialFibre treatment to obtain bast fibreProcess engineeringHigh pressure

Owner:WUHAN TEXTILE UNIV

Method of preparing textile fabric by degumming environment-friendly type crude hemp

InactiveCN100535203CEmissions reachedReduce dosageFibre treatment to obtain bast fibreTextile fiberOrganosolv

The invention discloses a method for preparing textile fibers by degumming environmentally friendly raw hemp, which comprises (1) mixing an organic solvent with a mass ratio of 4:1-2:1 and raw hemp at a temperature of 60-120°C, Scouring for 2-5 hours to extract the lignin in the original hemp; (2) use the organic degumming solution of hydrogen peroxide as pectin and hemicellulose remover for the hemp fiber after delignification, and start from room temperature in half an hour Raise the temperature to 50-100°C and keep it warm for 1-4 hours to obtain hemp fiber for textile. The degumming and bleaching method of the invention is practical and effective, and the obtained hemp fiber can be used in the processing of various textiles, and high-grade lignin can be recovered at the same time, and the waste water can reach the discharge standard after treatment.

Owner:DONGHUA UNIV

Method for producing terylene fibre with pearly lustre

InactiveCN101381903BImprove performanceAdd lessFilament/thread formingPigment addition to spinning solutionPolyesterLight extinction

The invention relates to a method for preparing polyester fibers with pearly luster. The method comprises the following steps: (1) pearlescent pigment agglomerate and full-dull PET fiber forming resin slice are blended according to the weight ratio of 5-20 to 80-95; and after drying, the water content is less than 100PPM, and the slice is delivered to a feeding port of an extruder and enters an screw extruder for heat fusing and compression; (2) the temperature is controlled to between 290 and 305 DEG C, fusant extruded out by the rotary screw rod enters a metering pump through a distributingpipe and a static mixer, delivered to a spinning component, filtered by a sea sand layer and pressed into a spinning plate to form fusant current which is cooed to form in a spinning cabinet, and thesurface of a filament bundle is covered by a spinning finish; and 3. the spinning speed pre-extension is between 2, 500 and 3, 500m / min, the winding carry rate is between 5 and 15 percent for wind-forming, and the full-dull pearlescent polyester fiber POY is obtained. The manufacturing process is easily realized, and is convenient to improve the pearlescent fiber spinning effect and simultaneously provides the fibers with light extinction performance, and the pearlescent pigment has excellent performance and little feed rate.

Owner:DONGHUA UNIV

A kind of processing technology of mantis shrimp meat floss

ActiveCN104432251BHigh economic valueAdd flavorFood ingredient as mouthfeel improving agentFiberShrimp

The invention discloses a processing technology of dried squillid meat floss. The processing technology comprises the following steps: (1) cooking; (2) cooling; (3) getting meat; (4) squeezing; (5) rubbing dried meat floss with hands; (6) frying preliminarily; and (7) frying the dried meat floss. The processing technology of the dried squillid meat floss disclosed by the invention is simple in process step, low in equipment investment, strong in operability, capable of optimizing the seasoner formula and providing a dried squillid meat floss quality improver; the prepared dried squillid meat floss is good in flavor, uniform and consistent in color and luster, soft in mouthfeel, easy to digest and absorb, and extremely suitable for the old and the children to eat, the fibers are soft, fluffy and fleece-like. A novel way for deeply processing the squillid is developed, and therefore, the processing technology is beneficial for increasing the economic value of the squillid.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Compound crystal variation modification method of ramie fiber

InactiveCN103437151BLarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsMicrowaveCentrifugation

The invention relates to a compound crystal variation modification method of ramie fiber. The compound crystal variation modification method comprises following steps: the ramie fiber is delivered into a sealed container; a modification medium is added; the pressure of the sealed container is increased to be as large as a modification pressure, and then is decreased instantaneously; the ramie fiber is subjected to vacuumization, high speed centrifugation spinning drafting and microwave radiation; and the modification medium is removed so as to obtain the compound crystal variation modified ramie fiber.

Owner:DONGHUA UNIV +1

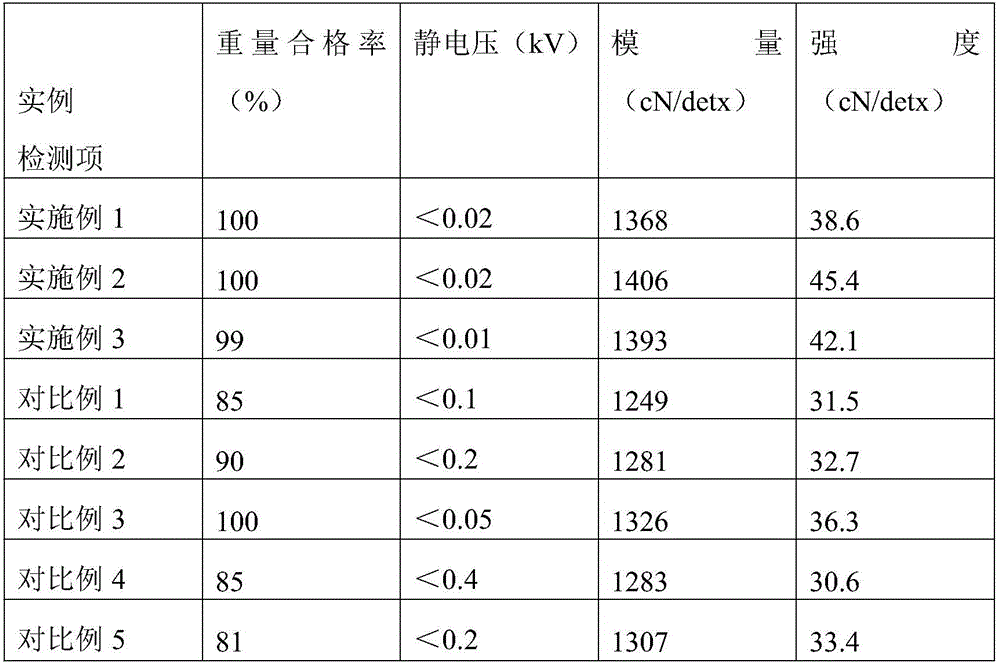

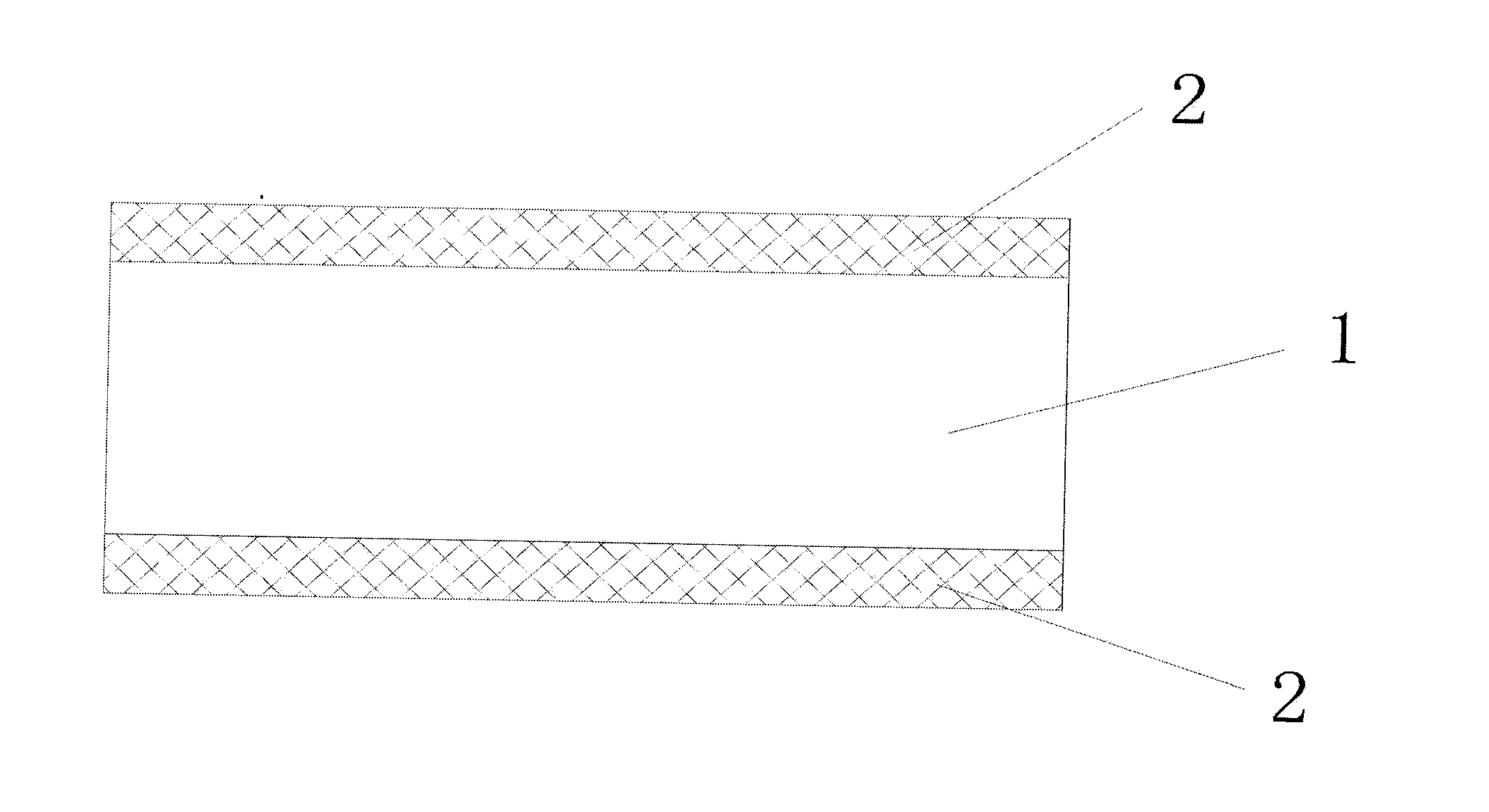

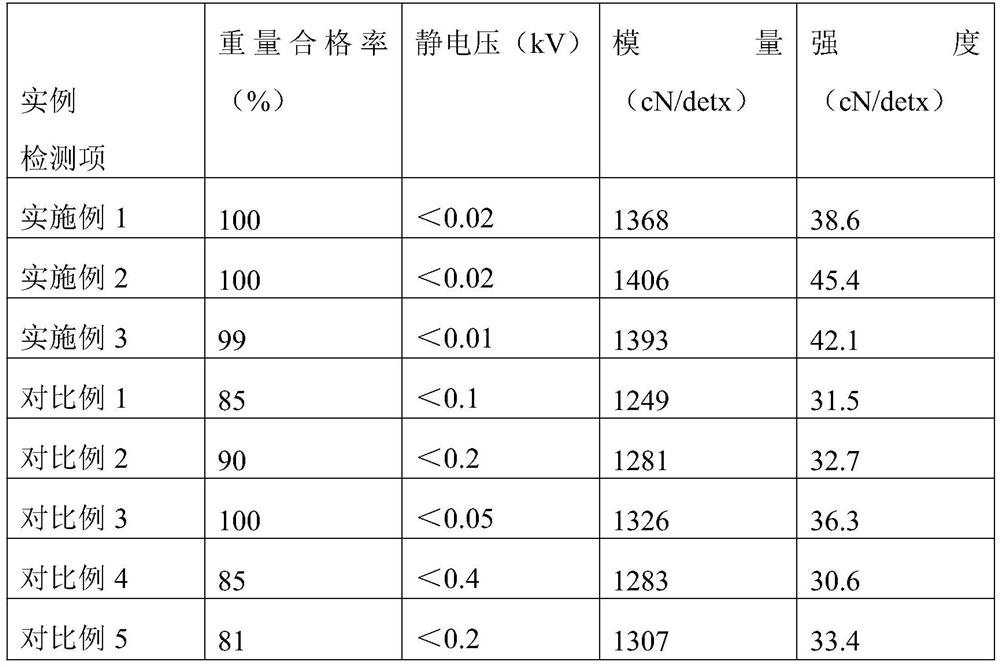

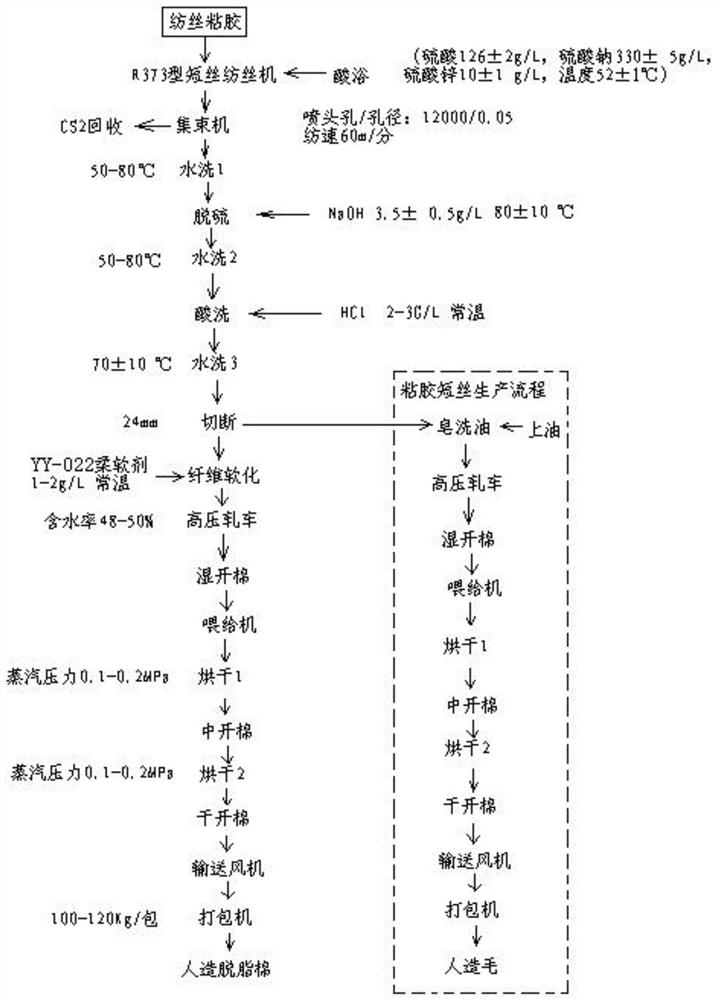

Production method of artificial degreasing cotton

InactiveCN114457581AEasy to openEasy to dryMonocomponent cellulose artificial filamentGrip property fibresChemical treatmentViscose

The invention discloses a production method of artificial degreasing cotton, which comprises the following steps of: spinning and gluing raw material cotton pulp, wood pulp or bamboo pulp, spinning by an R373 type staple fiber spinning machine, and bundling by a bundling machine; carrying out primary water washing on the clustered object in water at 50-80 DEG C, carrying out desulfurization treatment after primary water washing, carrying out secondary water washing in water at 50-80 DEG C, carrying out acid pickling treatment, and carrying out tertiary water washing in water at 70 + / -10 DEG C; cutting an object obtained after three times of water washing into 24mm line segments, adding a softening agent into a water tank, and carrying out fiber softening treatment at normal temperature; and after softening treatment, drying and packaging to obtain the artificial degreasing cotton. The raw materials of the artificial degreasing cotton are from cotton pulp, wood pulp and bamboo pulp, the sources are wide, and the problems that cotton is insufficient and the production cost is high are solved; the artificial degreasing cotton warp prepared through multiple times of physical and chemical treatment is high in fiber purity, adjustable in fiber length and thickness and soft and smooth in fiber.

Owner:邹蒙亮

Marine recycled fabric and preparation method thereof

PendingCN114230858AReduce pollutionSave raw materialsPlastic recyclingMonocomponent polyesters artificial filamentPolyesterYarn

The invention provides a preparation method of a marine recycled fabric, which comprises the following steps: sorting waste marine plastics, decontaminating, crushing, cleaning and dewatering to obtain a waste polyester raw material; the method comprises the following steps: adding a waste polyester raw material into a melting device for melting to obtain molten waste polyester; carrying out a depolymerization reaction on the molten waste polyester, an alcoholysis agent and an alcoholysis catalyst in an alcoholysis kettle to obtain a depolymer after alcoholysis; and carrying out repolymerization reaction on the alcoholysis depolymer to prepare regenerated polyester, spinning, coloring, and weaving to obtain the fabric. According to the preparation method provided by the invention, through multiple times of color screening, large difference of finally obtained yarn raw materials is avoided, and the influence on the weaving effect of the fabric is reduced; and during the repolymerization reaction, polyether polyol is added as an autocatalytic catalyst, so that the polyester crystal region prepared by repolymerization is enlarged, the fiber is softer, and the degree of dyeing is higher.

Owner:NINGBO DAQIAN TEXTILE

A kind of crystal change modification method of flax fiber

InactiveCN103437095BLarge poresReduce crystallinityLiquid/gas/vapor removalLiquid/gas/vapor treatment of definite length materialsPolymer scienceCrystal structure

The invention relates to a method for modifying flax fibers via crystal lattice change. The method comprises the following steps: putting flax fibers into an enclosed container; filling a modification medium; boosting to a modification pressure; releasing pressure momentarily; removing the modification medium to obtain flax fibers modified via crystal lattice change. Due to the adoption of the technical scheme, the method has the advantages that 1, the aim of modifying is fulfilled by changing a crystal lattice structure, the original defects are overcome by adopting the modified fibers, pores are increased, the degree of crystallization is lowered, fibers are soft, and the size stability, softness, dyeing performance and the like of a product are enhanced; 2, a method for releasing pressure momentarily is adopted, so that modified fibers expand to the maximum extent, the bulkiness and softness of the fibers are enhanced greatly, and the spinning, weaving and dyeing performance of the fibers is enhanced greatly.

Owner:DONGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com