Ultrahigh molecular weight polyethylene fiber and preparation method thereof

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber processing, stretch spinning, etc., can solve the problems of affecting post-processing, fiber electrification, etc., to eliminate static electricity, fiber softness , the effect of good social promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

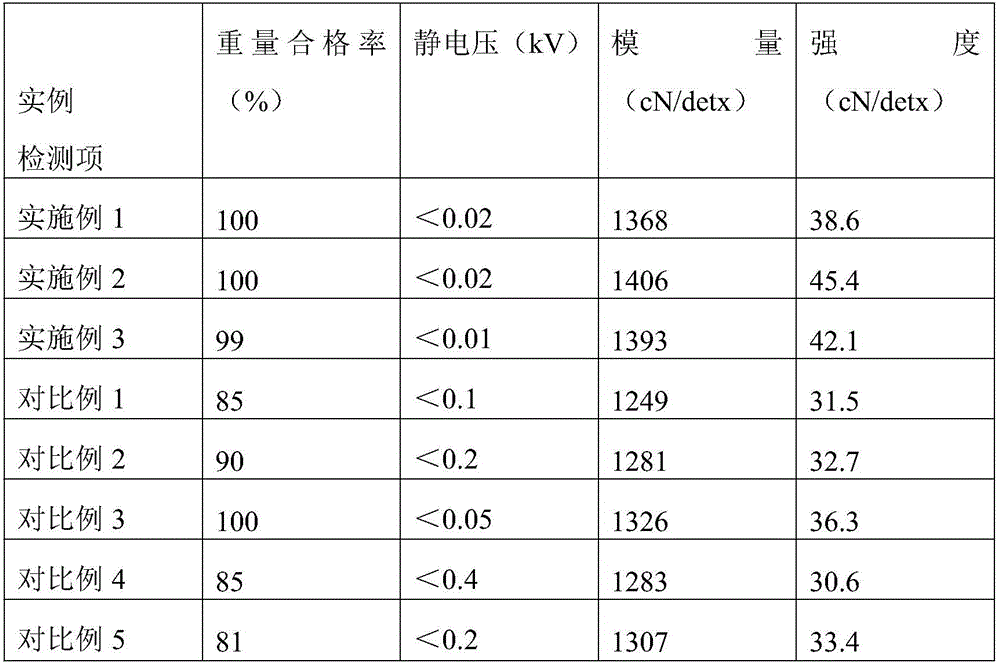

Examples

preparation example Construction

[0031] The present invention provides a method for preparing ultra-high molecular weight polyethylene fiber, which includes the following steps:

[0032] (1) The ultra-high molecular weight polyethylene frozen collagen yarn is prepared by the gel spinning method;

[0033] This process is well known to those skilled in the art, and specifically includes: feeding the ultra-high molecular weight polyethylene spinning dope into a twin-screw extruder for blending and extruding to obtain a first spinning solution, and then adding the first spinning solution. The spinning solution is fed into the spinning box, after being drawn and rapidly cooled to solidify, ultra-high molecular weight polyethylene frozen collagen filaments are obtained; wherein the weight average molecular weight of the ultra-high molecular weight polyethylene used in the present invention is preferably 3 to 5×10 6 In the present invention, it is more preferable to use the first ultra-high molecular weight polyethylene a...

Embodiment 1

[0049] Example 1 Preparation of ultra-high molecular weight polyethylene fiber

[0050] a. The ultra-high molecular weight polyethylene 150D frozen collagen yarn is prepared by the gel spinning method;

[0051] b. After the frozen collagen filament is balanced, it is pre-drawn, extracted, dried, and then hot-drawn at no less than three levels to obtain 150D fiber.

[0052] c. The obtained fiber passes through a coating roller with an antistatic bath liquid, and then passes through a hot box to heat-set while drying to obtain a 150D product of ultra-high molecular weight polyethylene low-static fiber.

[0053] The bath is a mixture of antistatic liquid and water, and the antistatic liquid is a quaternary ammonium salt cationic high-efficiency antistatic agent composed of 30% dodecyldimethylethylammonium bromide, dodecyldimethylhydroxyl 30% ethyl ammonium chloride and 40% didodecyl dimethyl ammonium chloride, the concentration of the upper liquid is 0.3%, the surface of the coating roll...

Embodiment 2

[0054] Example 2 Preparation of ultra-high molecular weight polyethylene fiber

[0055] The processes a and b are the same as in Example 1, to obtain 200D fibers.

[0056] c. The process is the same as in Example 1, but the concentration of the liquid is 0.5%, and the liquid speed of the coating roller is 6m / min; a 200D product of ultra-high molecular weight polyethylene low-static fiber. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com