Production method of artificial degreasing cotton

A production method and technology of absorbent cotton, which is applied in the direction of single-component cellulose rayon, textiles and papermaking, and improved hand-feeling fibers, etc., which can solve the problems of vulnerability to insect pests and climate, high production cost of absorbent cotton, insufficient supply of absorbent cotton, etc. problem, to achieve the effect of making up for the high production cost, making up for the shortage of cotton, and making the fiber soft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

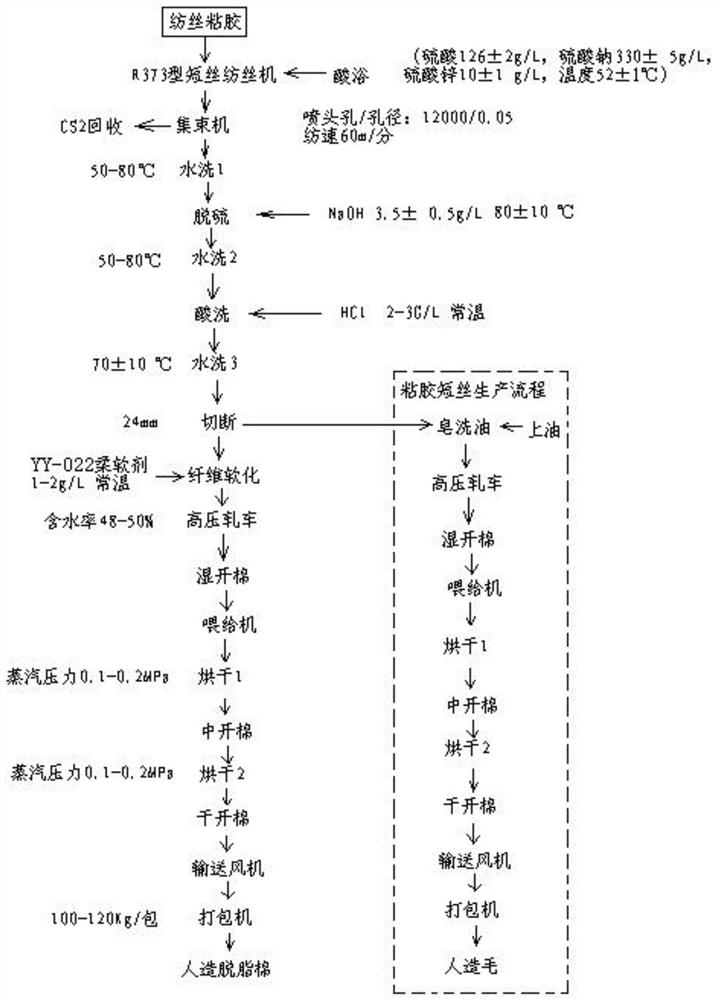

[0031] see figure 1 , the present invention provides a kind of technical scheme: a kind of production method of artificial absorbent cotton, this production method comprises the steps:

[0032] The first step: spinning bundle

[0033] Firstly, the raw material cotton pulp, wood pulp or bamboo pulp is spun into viscose, and after being spun by the R373 short-filament spinning machine, it is bundled by a bundling machine;

[0034] The second step: desulfurization washing

[0035] The bundled product is washed once in water at 50-80°C, desulfurized after washing once, washed twice in water at 50-80°C, pickled after that, and then washed in water at 70±10°C wash three times;

[0036] The third step: cutting and fiber softening

[0037] The gain after washing three times is cut into a line segment of 24mm, and softening agent is added in the water tank to carry out fiber softening treatment at normal temperature;

[0038] Step Four: Drying

[0039] The resultant after the fib...

Embodiment example 2

[0050] The present invention provides a technical solution: using wood pulp as raw material to produce artificial absorbent cotton according to the production method described in Example 1.

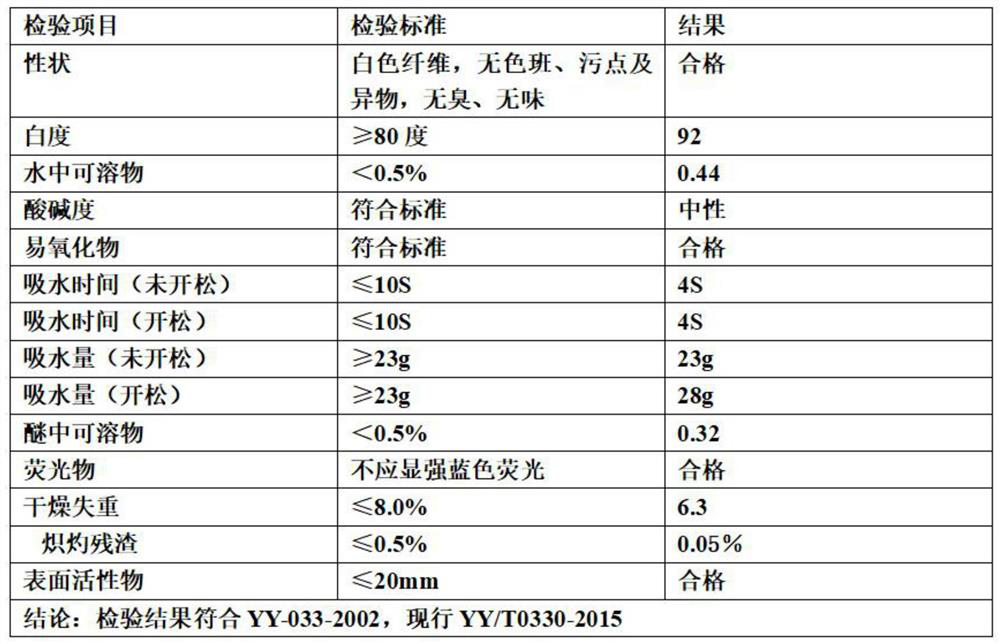

[0051] For the test data of artificial absorbent cotton made of wood pulp, please refer to figure 2 , it can be seen that the test data of wood pulp artificial absorbent cotton has reached the various indicators of absorbent cotton, so wood pulp artificial absorbent cotton can fully supplement the supply of absorbent cotton and make up for the problems of insufficient cotton and high production costs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com