A kind of ultra-high molecular weight polyethylene fiber and its preparation method

An ultra-high molecular weight, polyethylene fiber technology, applied in the direction of single-component polyolefin rayon, fiber treatment, stretch spinning, etc., can solve the problems of fiber charging and affecting post-processing, etc., achieve fiber softness and eliminate static electricity , It is not easy to stick to sticks and roll around sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

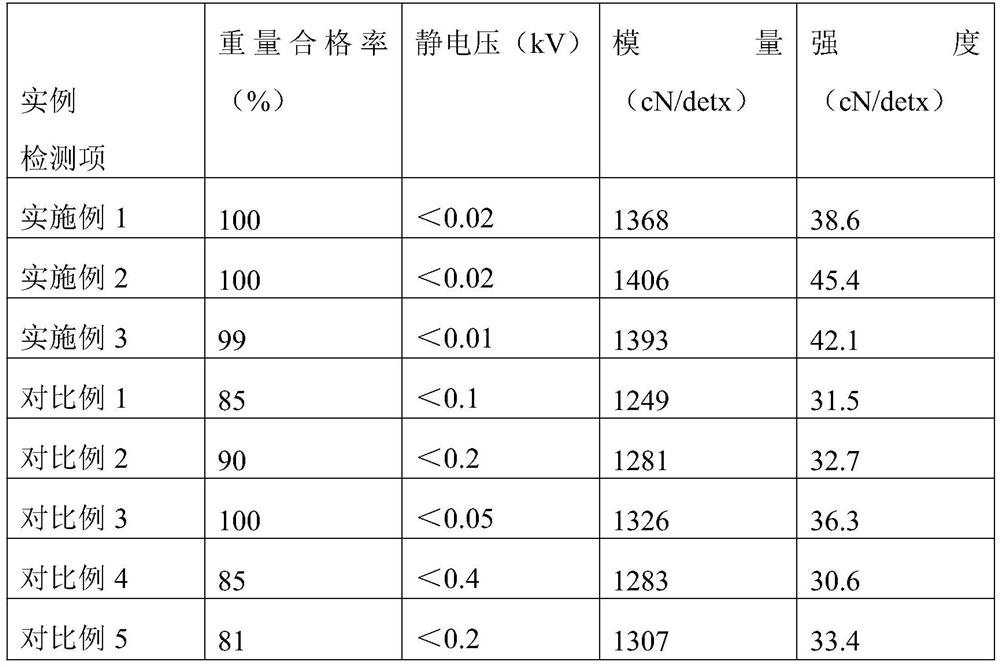

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of ultrahigh molecular weight polyethylene fiber, comprises the following steps:

[0032] (1) UHMWPE jelly collagen filaments are produced by gel spinning;

[0033] This process is well known to those skilled in the art, and specifically includes: sending the ultra-high molecular weight polyethylene spinning stock solution into a twin-screw extruder for blending and extrusion to obtain the first spinning solution, and then the first spinning solution The spinning solution is sent into the spinning box, and after drawing and rapid cooling and solidification, ultra-high molecular weight polyethylene jelly collagen filaments are obtained; wherein the weight-average molecular weight of the ultra-high molecular weight polyethylene used in the present invention is preferably 3 to 5×10 6 , the present invention more preferably adopts the first ultra-high molecular weight polyethylene and the second ultra-high molecular weight...

Embodiment 1

[0049] The preparation of embodiment 1 ultra-high molecular weight polyethylene fiber

[0050] a. UHMWPE 150D jelly collagen filaments are prepared by gel spinning method;

[0051] b. After the jelly collagen filaments are balanced, they are pre-drawn, extracted, and dried in sequence, and then thermally drawn at no less than three levels to obtain 150D fibers.

[0052] c. The obtained fiber passes through a coating roller with an antistatic bath, then passes through a hot box, and heat-sets while drying to obtain a 150D product of ultra-high molecular weight polyethylene low-static fiber.

[0053] The bath liquid is a mixture of antistatic liquid and water. The antistatic liquid is a quaternary ammonium salt cationic high-efficiency antistatic agent consisting of 30% dodecyldimethylethylammonium bromide, dodecyldimethylhydroxyl Ethyl ammonium chloride 30% and didodecyl dimethyl ammonium chloride 40%, the upper solution concentration is 0.3%, the roller surface of the coating...

Embodiment 2

[0054] The preparation of embodiment 2 ultra-high molecular weight polyethylene fibers

[0055] The processes of a and b are the same as those in Example 1 to obtain 200D fibers.

[0056] c. The process is the same as in Example 1, but the concentration of the liquid is 0.5%, and the liquid speed of the coating roller is 6m / min; the 200D product of the ultra-high molecular weight polyethylene low-static fiber. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com