Production method of polyester profiled fiber plated with indium tin oxide

A technology of indium tin oxide plating and production method, which is applied in the field of polyester special-shaped fiber production, can solve the problems that the filaments and short fibers of the film layer of indium tin oxide plating are not seen, and achieve simple production equipment, soft fibers, and smooth process short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Production equipment: roll-to-roll magnetron sputtering coating machine.

[0010] Substrate: polyester film with a thickness of 6 μm.

[0011] Target material: an indium tin oxide target with a purity of 99.99% (sintered from 97wt% In2O3 and 3wt% SnO2).

[0012] Production conditions: the purity of the working air for sputtering is 99.99% argon (AR), the background vacuum degree of the vacuum chamber is 10-3Pa, the distance between the substrate and the target is fixed at 0.12m, the working pressure is 0.3Pa, and the winding speed is 10m / min, the sputtering power is 1500W.

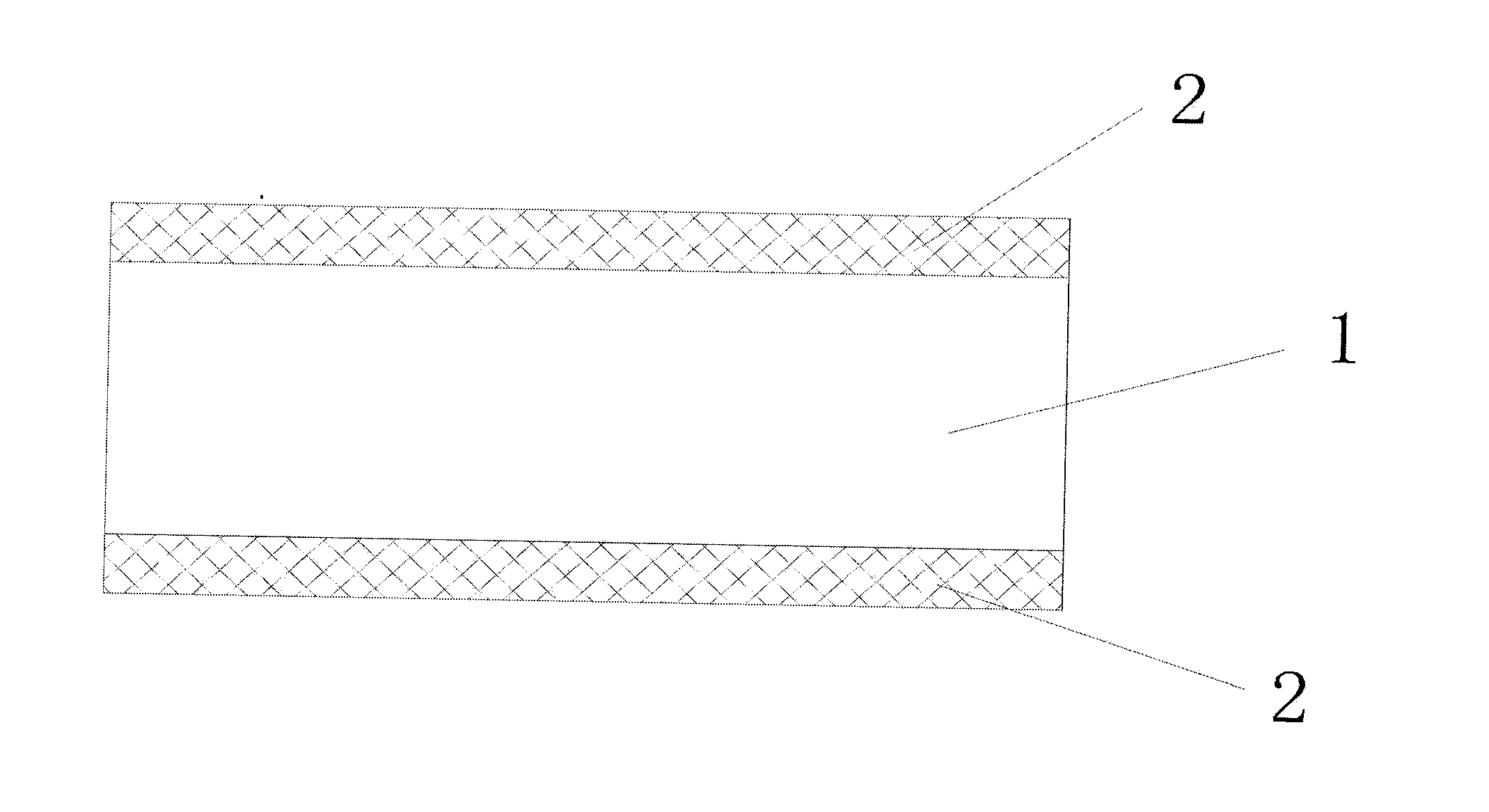

[0013] After coating the polyester film on both sides, it is finely cut, and the cutting width is 0.1mm. Then roll forming is carried out. Since the thickness of the film is only 6μm, the cutting width is only 0.1mm, so the flexibility is good, and the wound fiber filaments can be cut again, and the cutting distance is 25mm. That is, polyester staple fibers coated with an indium tin oxide film l...

Embodiment 2

[0015] Production equipment: roll-to-roll magnetron sputtering coating machine.

[0016] Substrate: polyester film with a thickness of 35 μm.

[0017] Target material: an indium tin oxide target with a purity of 99.99% (sintered from 97wt% In2O3 and 3wt% SnO2).

[0018] Production conditions: the purity of the working air for sputtering is 99.99% argon (Ar), the background vacuum degree of the vacuum chamber is 10-3Pa, the distance between the substrate and the target is fixed at 0.12m, the working air pressure is 0.3Pa, and the winding speed is 2m / min, the sputtering power is 2000W.

[0019] After coating the polyester film on both sides, it is finely cut, and the cutting width is 0.65mm. Then roll forming is carried out. That is, a polyester filament coated with an indium tin oxide film layer and having a rectangular cross section is obtained. The specific specifications are: the width of the polyester filament cross-section is 0.65mm, the thickness is 35μm, and the thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com