Ecological floating bed suitable for high-sediment large-flow rate water body

An ecological floating bed and high flow rate technology, applied in the field of equipment, can solve the problems of reducing the specific surface area, affecting the service life, breaking the central rope, etc., achieving the effect of large contact area, prolonging the service life and reducing the water flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

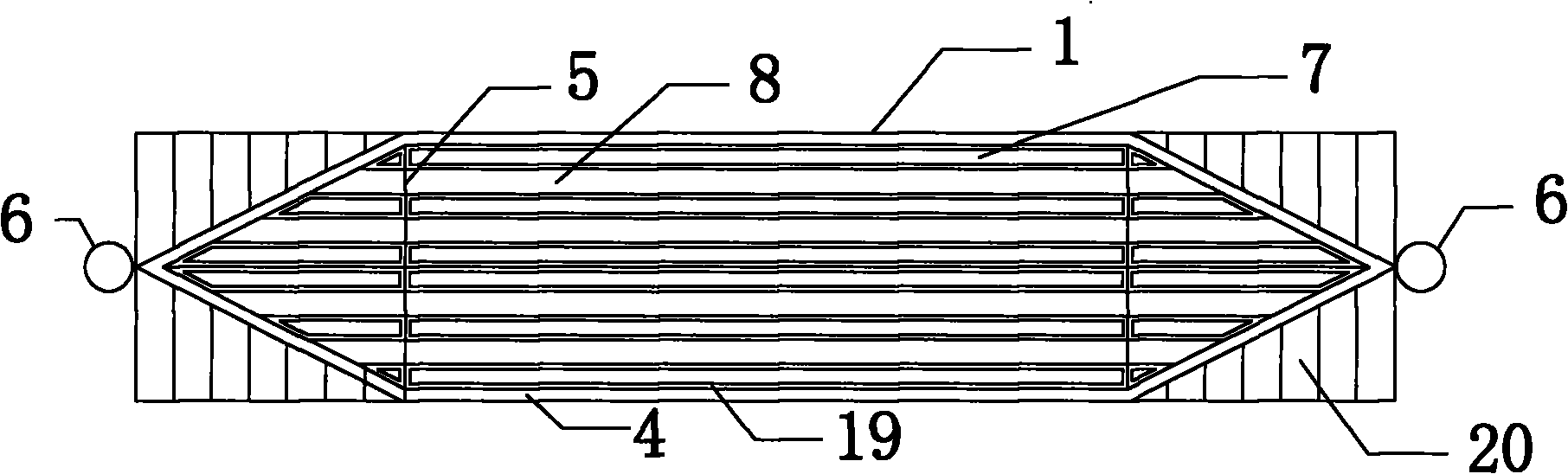

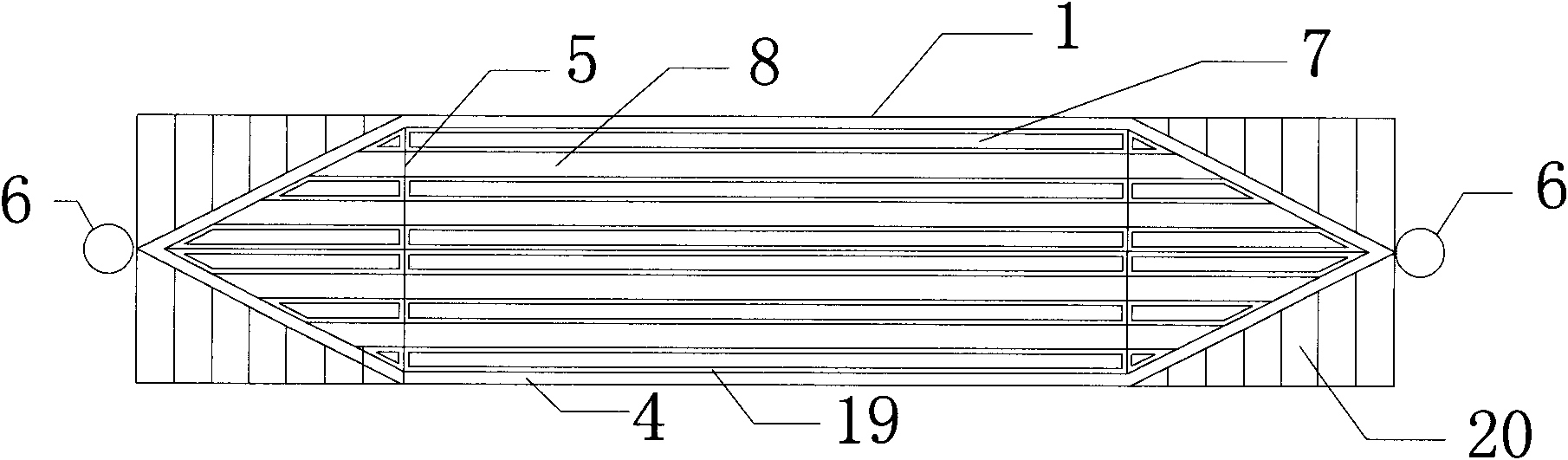

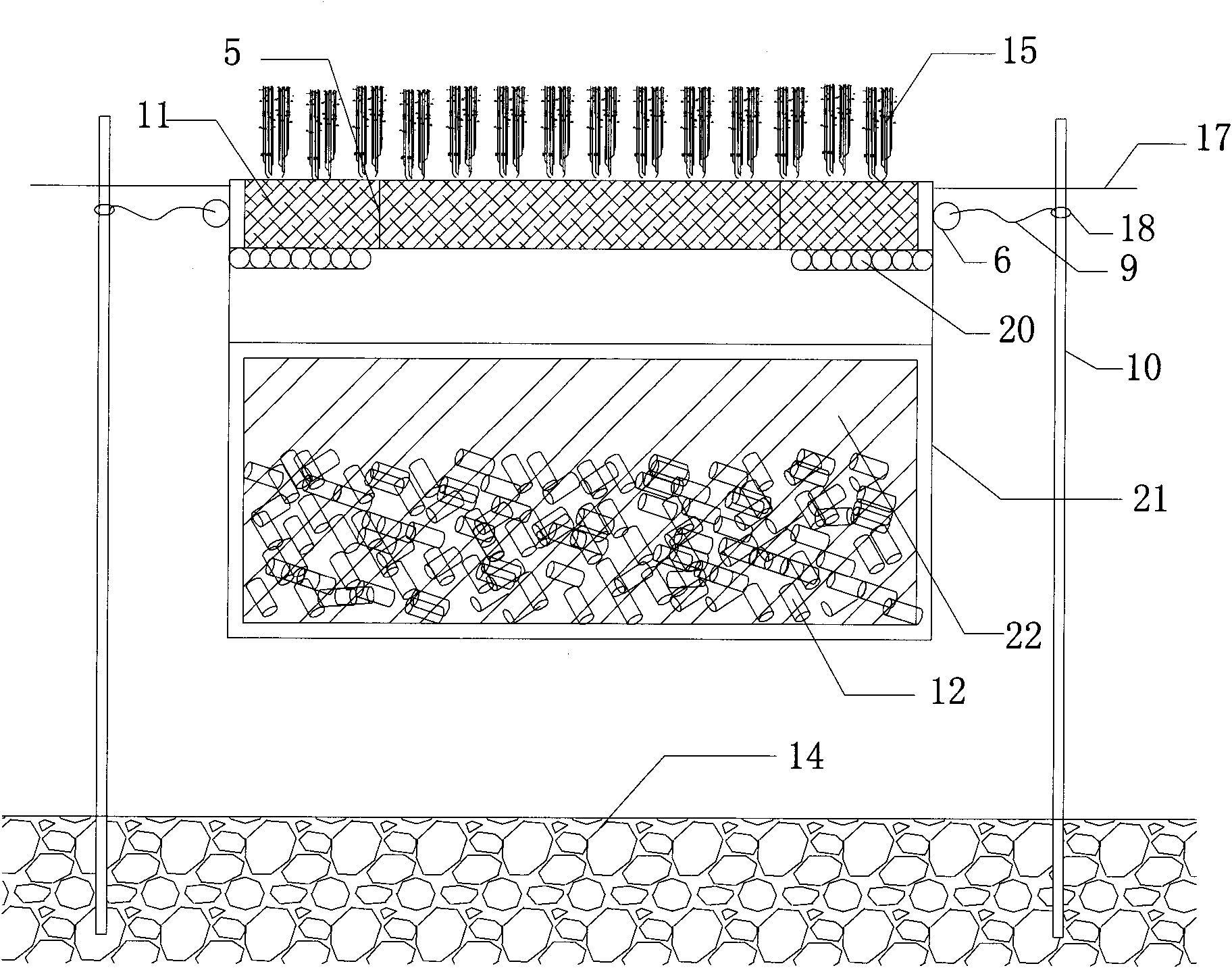

[0025] An ecological floating bed suitable for high sediment and high velocity water bodies, including two floating bed units 1.

[0026] As shown in FIG. 1, the floating bed unit 1 includes a floating bed fixing rod 5, a hollow PVC pipe 19, a wave elimination row 20 and a gauze 22. The floating bed fixing rod 5 fixes several hollow PVC pipes 19 in a horizontal arrangement to form a floating row. The hollow PVC pipe 19 in the middle is used as a reference, the lengths of the hollow PVC pipes 19 on the left and right sides are successively decreased, and the midpoints of the hollow PVC pipes 19 are located on the same line. The floating row is fixed around the frame 4. The interval between two adjacent hollow PVC pipes 19 is the diameter of the hollow PVC pipe 19. The distance between the tubes is fixed to form an independent water-gas exchange zone 8. Then, the upper surface of the hollow PVC pipe 19 is hollowed out to form a plant area 7, and a planting substrate 11 is covered...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com