A dropper solid-phase extraction device and method and the preparation method of the device

An extraction device and dropper technology, applied in the field of sample pretreatment, can solve the problems of being washed out and the adsorption bed is easy to loosen, etc., and achieve the effects of simple operation, less sample and solvent consumption, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

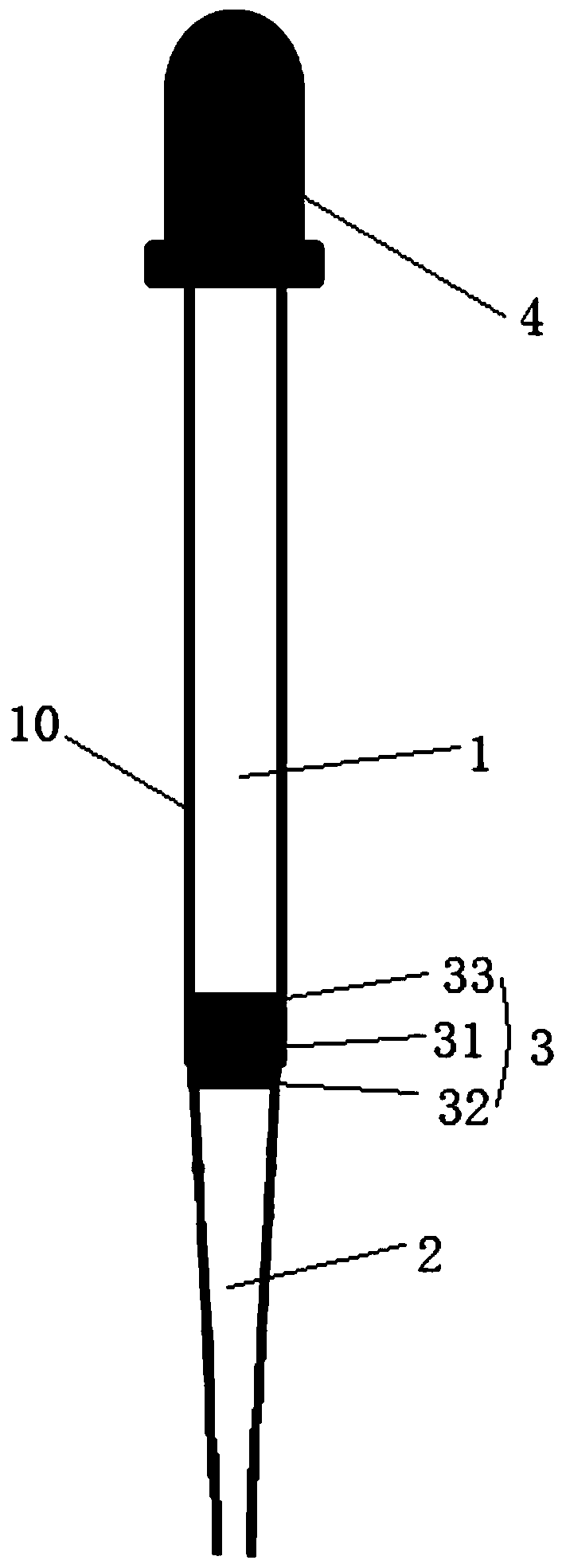

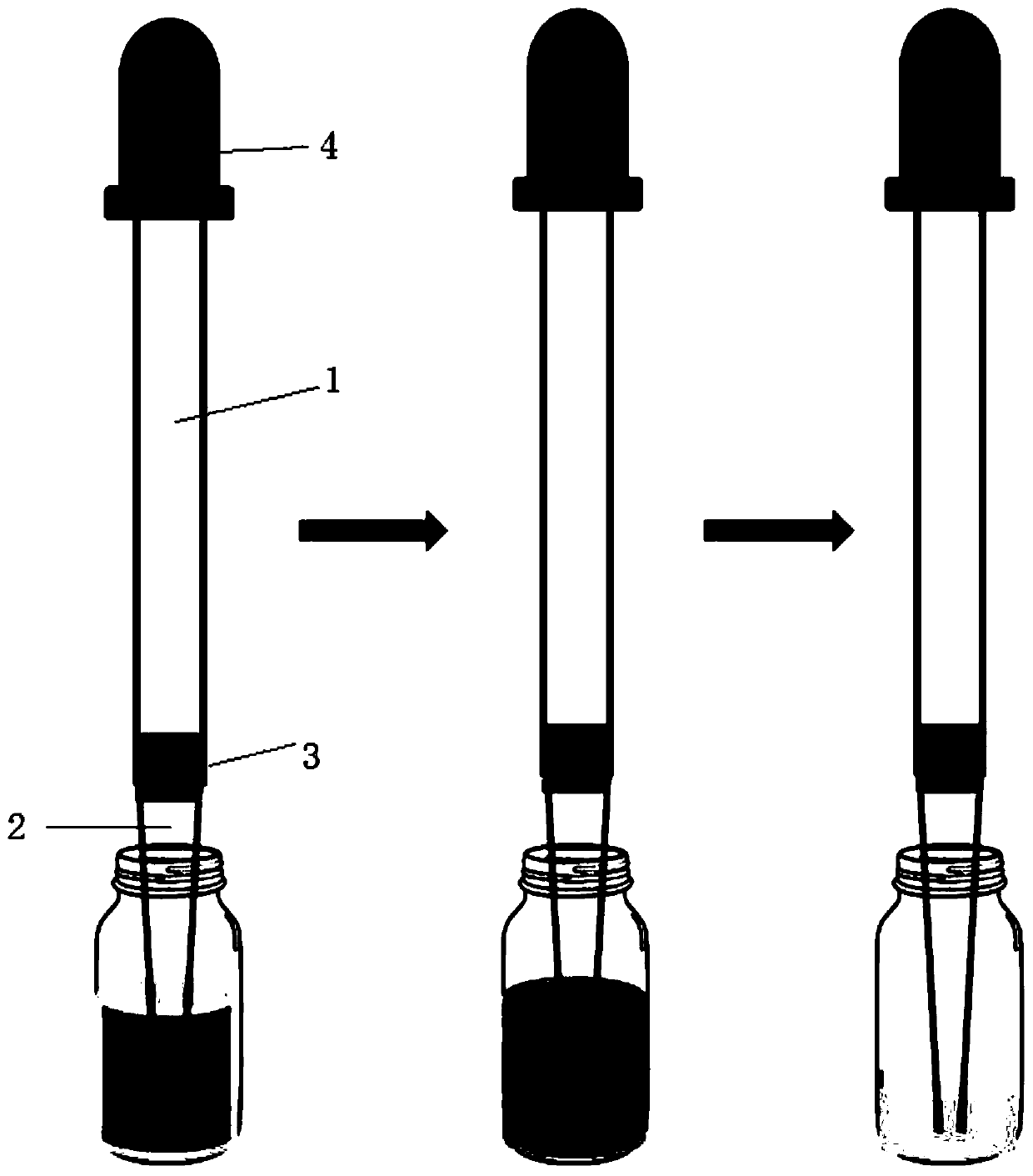

[0035] Please refer to figure 1 , the embodiment of the present invention provides a kind of burette solid phase extraction device, comprises power unit 4 and solid phase extraction container 10, and described burette solid phase extraction device is applied to non-aqueous medium solid phase extraction, and described solid phase extraction The manufacturing material of container 10 is glass, and the solvent contained in described solid-phase extraction container 10 is non-polar or weakly polar solvent, and described power unit 4 is arranged on the top of solid-phase extraction container 10, by extruding power unit 4 The solid phase extraction in the solid phase extraction container 10 is realized. The device uses glass as the material for the solid-phase extraction container 10, so that the device can effectively avoid the interference of the plasticizer during the extraction of the non-aqueous medium during the solid-phase extraction process. For example, when the sample is a...

Embodiment 2

[0052] The difference between this embodiment and embodiment 1 is that the length of the first connecting pipe 1 is preferably 4 cm, the length of the second connecting pipe 2 is preferably 8 cm, the amount of the particle adsorbent is 20 mg, and the cotton The dosage is 2mg. The rest are basically the same as in Example 1.

Embodiment 3

[0054] The difference between this embodiment and embodiment 1 is that the length of the first connecting pipe 1 is preferably 7cm, the length of the second connecting pipe 2 is preferably 18cm, the amount of the fiber adsorbent is 20mg, and the cotton The dosage is 4mg. The rest are basically the same as in Example 1.

[0055] 10 μL of silanization derivatization reagent (N-tert-butyldimethylsilyl-N-methyltrifluoroacetamide, MTBSTFA) was added to the desorption solution obtained above, shaken at room temperature for 5 min, and then analyzed by gas chromatography-mass spectrometry.

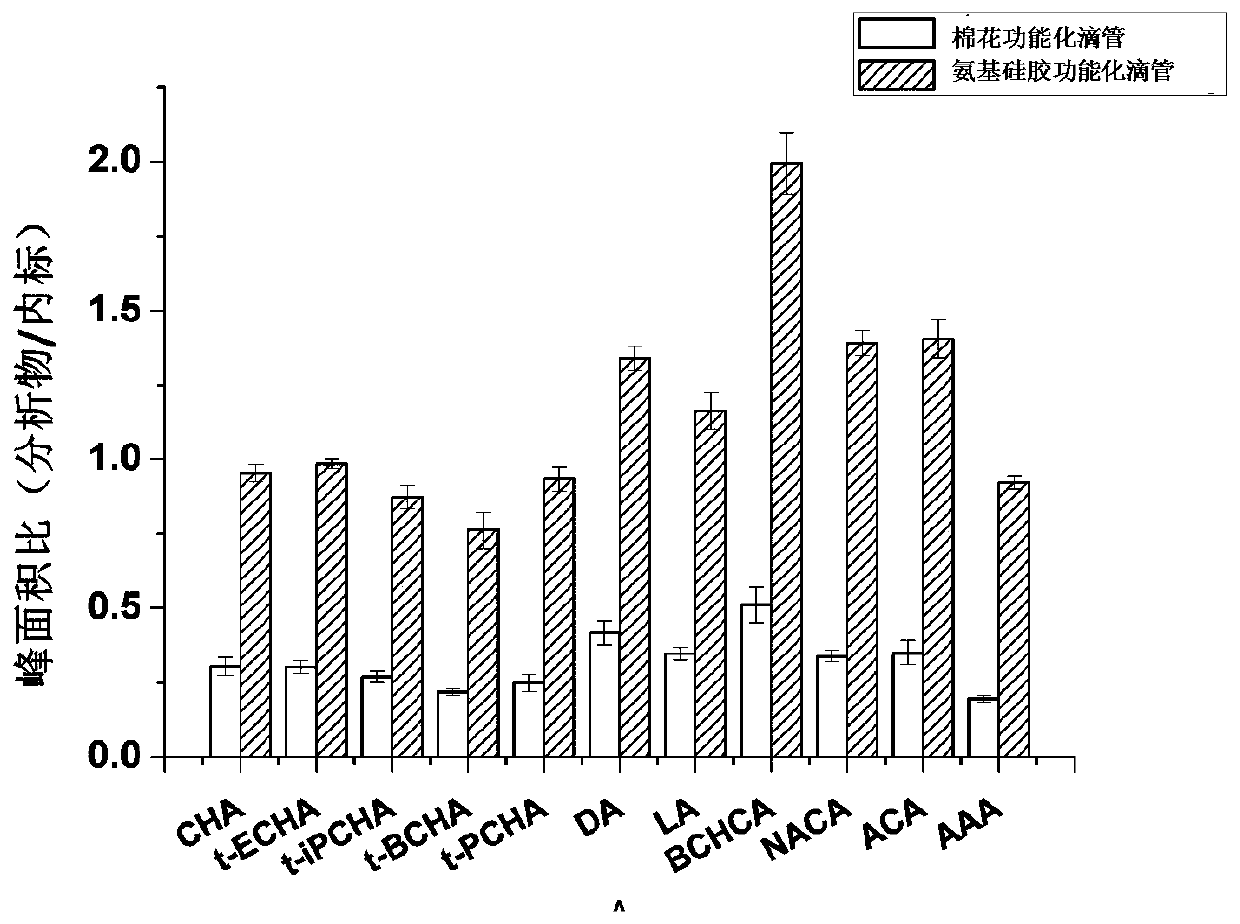

[0056] image 3 It is a comparison chart of the extraction efficiency of the filler in the filler layer 31 in the present invention is an amino silica gel dropper and a cotton functionalized dropper. The results show that the extraction effect of the present invention is obviously better, and this is because the effective site for adsorbing petroleum acid on the surface of amino silica gel is mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com