Crumb rubber modified asphalt and prepration method thereof

A technology for modifying asphalt and waste rubber, which is applied in building components, building insulation materials, construction, etc., and can solve the problem of low stability of waste rubber powder modified asphalt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

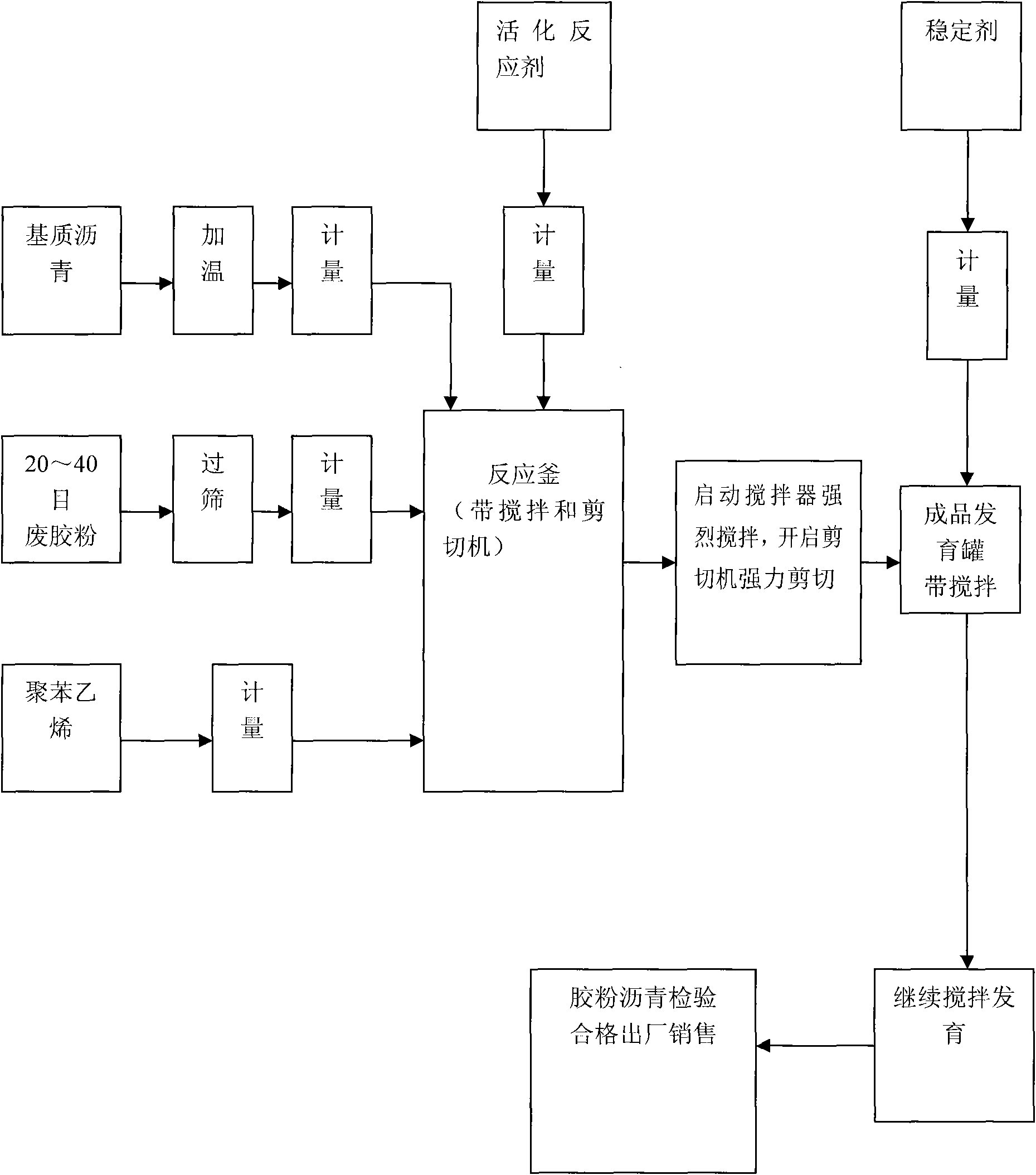

[0030] As shown in the figure, a waste rubber modified asphalt, which includes: waste rubber powder, polystyrene particles, matrix asphalt, high-efficiency activation reactant, stabilizer, and its weight ratio is: waste rubber powder 20- 25 parts, 8-12 parts of polystyrene particles, 75-80 parts of base pitch, 0.2-0.5 parts of high-efficiency activation reactant, and 0.5-0.7 parts of stabilizer.

[0031] The preparation process is as follows:

[0032] A. The base asphalt is heated to 180-190°C in the raw material tank, and the metered 75-80 parts by weight of the high-temperature base asphalt is pumped to the reactor that can be heated and kept warm, and the agitator on the reactor is activated for stirring Base pitch in the reactor;

[0033] B. Put the measured 20-25 parts by weight of waste tire rubber powder (20-40 mesh) and 8-12 parts by weight of polystyrene particles into the reactor in turn, keep stirring during the process of no feeding, and stir in the reactor Under the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com