Novel efficient spraying heavy ground-floor plastering gypsum mortar

A plastering gypsum, high-efficiency technology, applied in the field of building materials, can solve the problems of uneven stirring, low construction efficiency, low construction quality, etc., and achieve the effects of high coating rate, high construction efficiency, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: A new type of high-efficiency spraying heavy bottom plaster gypsum mortar, including the following components by weight: 580 parts of flue gas desulfurization gypsum, 100 parts of ordinary Portland cement, 150 parts of Shuangfei powder, and 100 parts of talcum powder , 200 parts of quartz sand, 0.8 parts of retarder, 20 parts of redispersible latex powder, 4 parts of cellulose ether, 2 parts of wood fiber, 1.8 parts of starch ether, 1.5 parts of thixotropic lubricant, 2 parts of polyacrylamide, Among them, the quartz sand is composed of 30-mesh quartz sand and 70-mesh quartz sand, and its weight ratio is 3:1. The particle size of Shuangfei powder is less than 75 μm, and the particle size of talcum powder is less than 75 μm. The retarder is composed of protein retarder and gluconic acid Class common composition, its weight ratio is 3:7, the viscosity of cellulose ether is 30000-75000mPa.s.

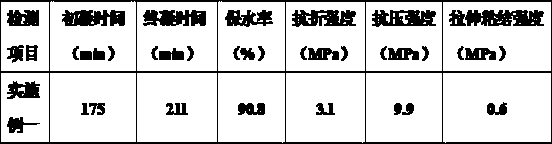

[0017] Table 1: The laboratory detects the test data of embodiment...

Embodiment 2

[0019] Embodiment 2: A new type of high-efficiency spraying heavy bottom plaster gypsum mortar, including the following components by weight: 500 parts of flue gas desulfurization gypsum, 88 parts of ordinary Portland cement, 110 parts of Shuangfei powder, and 150 parts of talcum powder , 120 parts of quartz sand, 0.7 parts of retarder, 20 parts of redispersible latex powder, 4 parts of cellulose ether, 2 parts of wood fiber, 1.8 parts of starch ether, 1.5 parts of thixotropic lubricant, 2 parts of polyacrylamide, Among them, the quartz sand is composed of 30-mesh quartz sand and 70-mesh quartz sand, and its weight ratio is 3:1. The particle size of Shuangfei powder is less than 75 μm, and the particle size of talcum powder is less than 75 μm. The retarder is composed of protein retarder and gluconic acid Class common composition, its weight ratio is 3:7, the viscosity of cellulose ether is 30000-75000mPa.s.

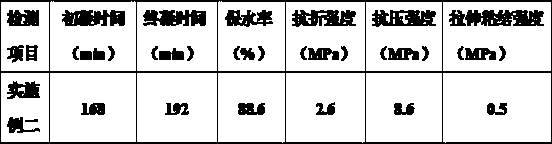

[0020] Table two: the experimental data that the laboratory detects...

Embodiment 3

[0022] Embodiment 3: A new type of high-efficiency spraying heavy bottom plaster gypsum mortar, including the following components in weight ratio: 680 parts of flue gas desulfurization gypsum, 50 parts of ordinary Portland cement, 60 parts of Shuangfei powder, 60 parts of talcum powder , 110 parts of quartz sand, 1 part of retarder, 24 parts of redispersible latex powder, 5 parts of cellulose ether, 3 parts of wood fiber, 2 parts of starch ether, 3 parts of thixotropic lubricant, 2 parts of polyacrylamide, Among them, the quartz sand is composed of 30-mesh quartz sand and 70-mesh quartz sand, and its weight ratio is 3:1. The particle size of Shuangfei powder is less than 75 μm, and the particle size of talcum powder is less than 75 μm. The retarder is composed of protein retarder and gluconic acid Class common composition, its weight ratio is 3:7, the viscosity of cellulose ether is 30000-75000mPa.s.

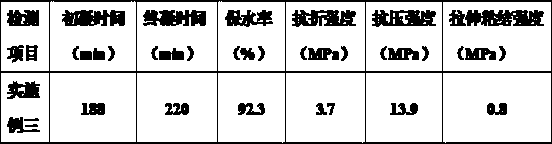

[0023] Table three: the test data that the laboratory detects to embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com