Flexible and controllable tobacco pulp preparation technology

A tobacco pulping and pulping technology, which is applied in the directions of tobacco, tobacco preparation, non-woody plant/crop pulp, etc., can solve the problems of poor slurry uniformity, high energy consumption for high-consistency refining, and difficulty in control, etc. The effect of paper bulk, saving power consumption for beating, and avoiding over-refining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

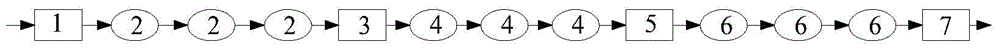

[0015] A flexible and controllable tobacco pulp refining process, such as figure 1 shown, including the following steps:

[0016] (1) Medium-consistency refining: Tobacco raw materials are passed into the medium-consistency beating tank 1 after preliminary thawing and squeezing, and the mass percentage concentration is 5% detected by a densitometer, and the beating degree is 8 °SR through online detection. Slurry is sent to three medium-consistency refiners 2 connected in series, and the beating degree is detected again after medium-consistency refining, and the beating degree is 18°SR, and it is transported to the medium-consistency beating pool 3;

[0017] (2) First-level low-consistency refining: the slurry in the medium-consistency pool 3 is adjusted to a mass percentage concentration of 3% through white water, and is first-level low-consistency grinding through three first-level low-consistency refiners 4 connected in series. Slurry, after on-line detection of beating de...

Embodiment 2

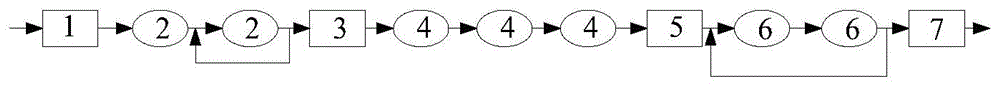

[0020] A flexible and controllable tobacco pulp refining process, such as figure 2 shown, including the following steps:

[0021] (1) Medium-consistency refining: Tobacco raw materials are passed into the medium-consistency beating tank 1 after preliminary thawing and squeezing, and the mass percentage concentration is 6% as detected by the density meter, and the beating degree is 12 °SR through the online detection. Slurry is sent to two medium-consistency refiners 2 connected in series, and the beating degree is checked again after medium-consistency refining. , the on-line detection of its percussion degree is 18 ° SR, and it is transported to the medium-concentrated after-percussion pool 3;

[0022] (2) First-level low-consistency refining: the slurry in the medium-consistency pool 3 is adjusted to a mass percentage concentration of 4% by white water, and is first-level low-consistency grinding through three first-level low-consistency refiners 4 connected in series. Sl...

Embodiment 3

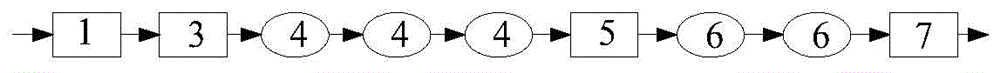

[0025] A flexible and controllable tobacco pulp refining process, such as image 3 shown, including the following steps:

[0026] (1) Medium-consistency refining: Tobacco raw materials are passed into the medium-consistency beating pool 1 after preliminary thawing and squeezing, and the mass percentage concentration is 10% detected by a densitometer. Transported to the medium-concentrated pool 3;

[0027] (2) First-level low-consistency refining: the slurry in the middle-consistency pool 3 is adjusted to a mass percentage concentration of 5% through white water, and is first-level low-consistency grinding through three first-level low-consistency refiners 4 connected in series. Slurry, after on-line detection of beating degree, if the beating degree is 24°SR, it will be transported to the low-concentration beating post-transition pool 5;

[0028] (3) Two-stage low-consistency refining: After low-consistency beating, the slurry in the transition tank 5 is transported to two s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com