Optimization system and method for sootblowing of circulating fluidized bed boiler

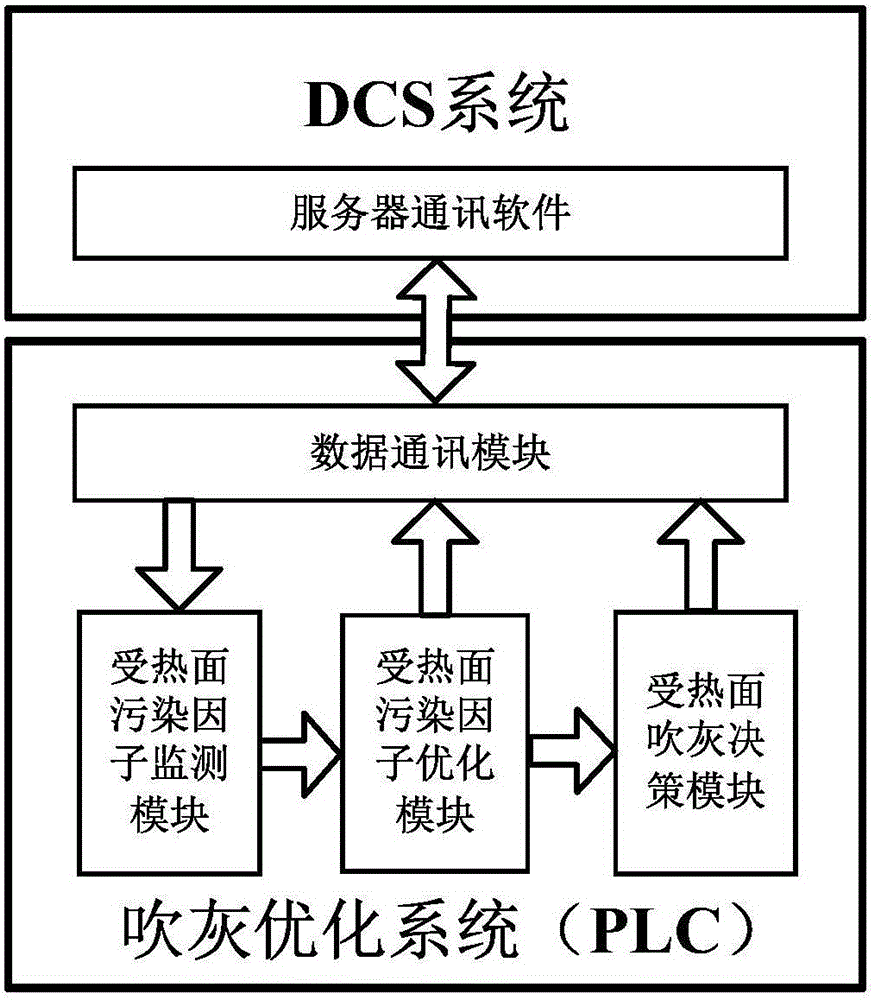

A circulating fluidized bed and boiler soot blowing technology, which is applied in the directions of fluidized bed combustion equipment, combustion methods, and fuel burned in a molten state, can solve the problems of shortening the life of the heating surface, over-blowing, under-blowing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

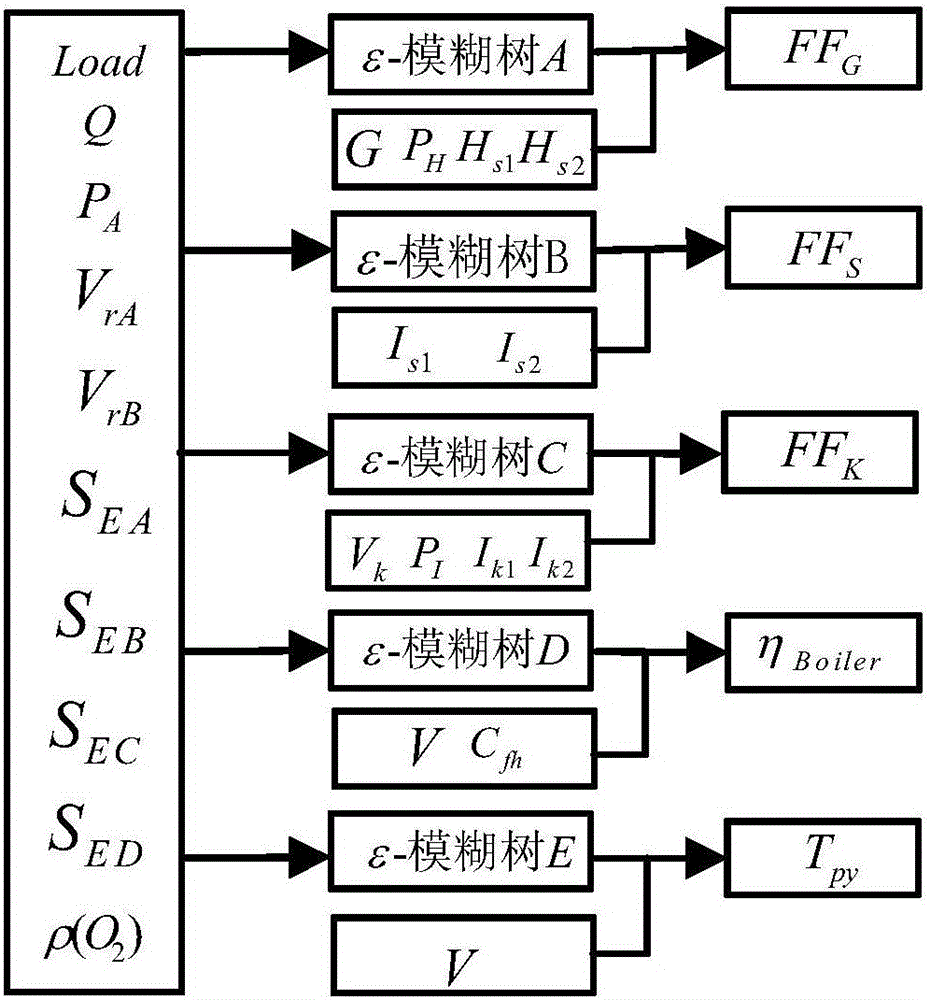

[0119] Taking a 300MW circulating fluidized bed boiler as the research object, two load intervals of 200MW~250MW and 250MW~300MW were studied respectively. The data communication module collected 3600 sets of data under different load sections, and the sampling time was 1s. 1000 groups are used as training samples, and 100 groups are used as test samples. In the test of the two-stage load, the overall effect of the 250MW~300MW load section is better.

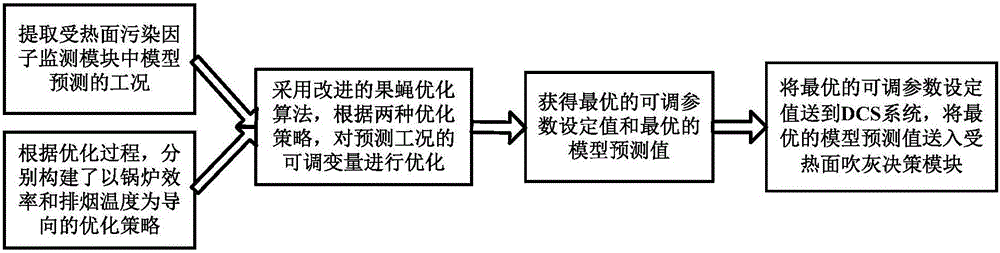

[0120] In the 250MW ~ 300MW load segment, set 7 fruit fly groups, that is, 7 adjustable variables (see Table 1), the number of fruit flies in each group is 40, and the number of iterations is 100. Based on the ε-fuzzy tree method FFG 、FF S 、FF K , T py , η Boiler The model has a small error, the relative error of the training sample is 0.27%, 0.19%, 0.21%, 0.36%, 0.15%, and the relative error of the prediction sample is 1.17%, 0.98%, 1.01%, 1.23%, 1.15% %. Among them, the boiler efficiency η Boiler With the oriented optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com