Corundum-zirconia corundum-titanic acid aluminum no-firing no-soaking sliding brick and preparation method thereof

A technology of aluminum titanate and zirconium corundum is applied in the field of corundum-zirconium corundum-aluminum titanate non-burning and non-impregnating sliding plate brick and its preparation field, which can solve the problem that the anti-melting loss performance of the sliding plate fluctuates greatly, the thermal melting loss increases, and the Wear resistance is weakened and other problems, to achieve the requirements of energy saving, consumption reduction and environmental protection control, to achieve reasonable reduction and control, and to improve the effect of high temperature comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

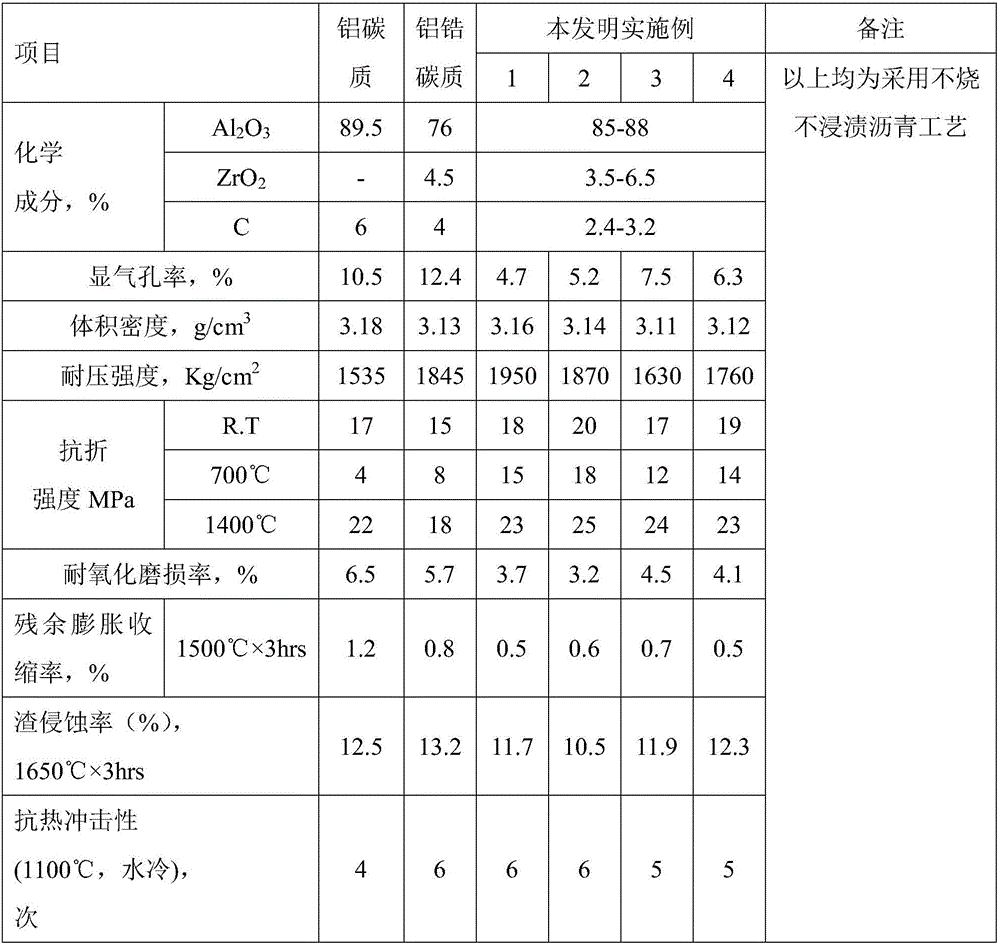

[0023] Below in conjunction with specific embodiment the embodiment of the present invention is further described:

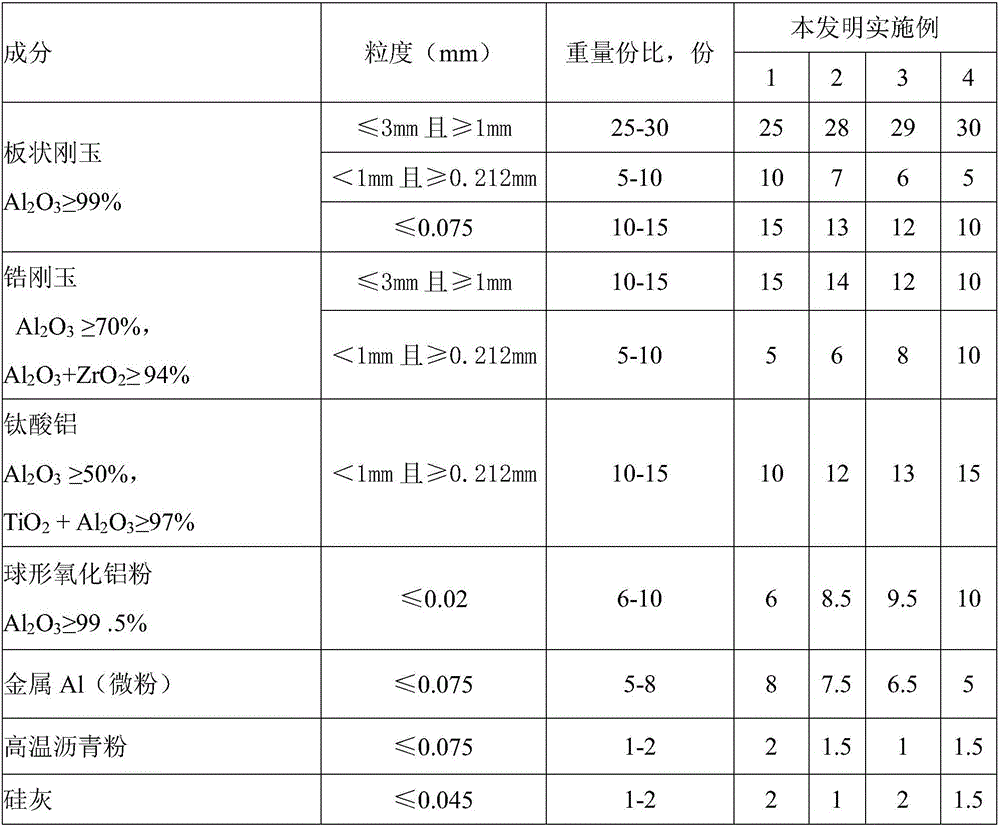

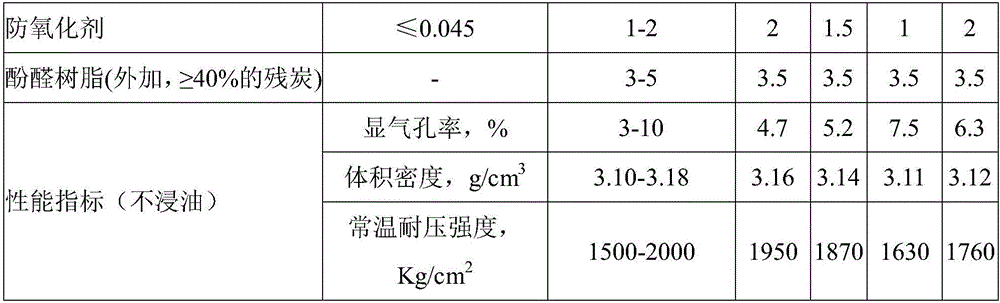

[0024] A corundum-zirconium corundum-aluminum titanate non-burning and non-impregnating sliding brick. The sliding brick is composed of the following components in parts by weight: 40-55 parts of tabular corundum, 15-25 parts of zirconium corundum, aluminum titanate 10-15 parts, spherical calcined alumina 6-10 parts, metal Al powder 5-8 parts, high-temperature asphalt powder 1-2 parts, silica fume 1-2 parts, antioxidant 1-2 parts, phenolic resin 3-5 parts .

[0025] The active ingredient Al of the tabular alumina 2 o 3 ≥99%, the amount of tabular alumina with a particle size of ≤3mm and ≥1mm is 25-30 parts, the amount of tabular alumina with a particle size of <1mm and ≥0.212mm is 5-10 parts, and the amount of tabular alumina with a particle size of ≤0.075mm The amount of corundum added is 10-15 parts.

[0026] In the above formula, the selected amount of ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com