Combustion optimization method based on coal quality on-line monitoring

A technology for combustion optimization and coal quality, applied in combustion methods, combustion chambers, and controlled combustion, can solve problems such as boiler efficiency decline, pollutant NOx emission increase, and frequent amplitude modulation

Active Publication Date: 2020-02-28

NANJING SCIYON AUTOMATION GRP

View PDF5 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] The invention provides a combustion optimization method based on coal quality online monitoring, which solves the problems of reduced boiler efficiency and increased pollutant N

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

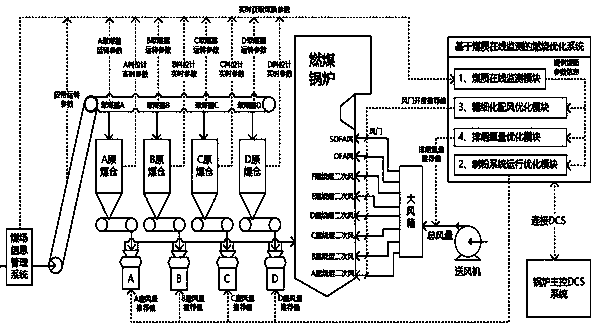

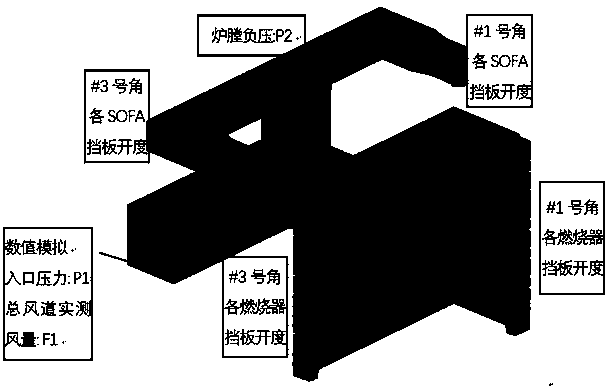

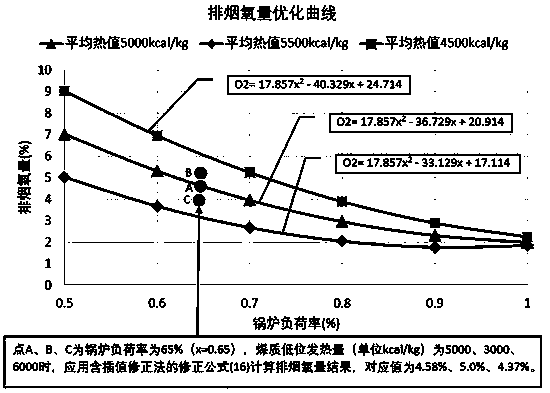

The invention discloses a combustion optimization method based on coal quality on-line monitoring. The method comprises a coal quality on-line monitoring method, an operation optimization method of apulverizing system based on coal quality on-line monitoring, a refined air distribution optimization method based on coal quality on-line monitoring, and a flue gas oxygen content optimization methodbased on coal quality on-line monitoring. Pulverizing system optimization realizes real-time optimization of the coal mill coal-air ratio, refined air distribution optimization realizes matching optimization of secondary air volume and burnout air volume of all burners, and fuel gas oxygen content optimization realizes total volume optimization. The combustion optimization method can adapt to thechange of coal quality and load to carry out dynamic real-time optimization, the boiler efficiency is effectively improved, and the emission of pollutants NOx is reduced.

Description

Technical field: [0001] The invention relates to a combustion optimization method based on coal quality on-line monitoring, in particular to the technical field of combustion optimization control technology for boilers of coal-fired power generation units. Background technique: [0002] Coal-fired thermal power generation units due to variable loads and coal types make the boiler combustion deviate from the designed coal type. Traditional boiler coordinated control optimization often cannot adapt to changes in coal quality, making the primary air rate and secondary air rate of the boiler operation , Ember wind rate, oxygen control, etc. have deviated from the optimal operating conditions. At present, the primary air rate, secondary air rate, and embers air volume rate are mainly adjusted manually by operating personnel based on experience. When the coal quality deviates greatly, problems such as frequent overheating of the water wall, slagging and burning of the burner nozz...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23M11/04F23N5/20F23N5/26G06Q10/04G06Q50/06

CPCF23M11/04F23N5/206F23N5/265G06Q10/04G06Q50/06

Inventor 刘国耀沈德明吴生辉陈福兵李扬

Owner NANJING SCIYON AUTOMATION GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com