Flue gas white smoke plume removing method for increasing heat energy utilization rate

A utilization rate and flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of low recycling rate, affecting the whitening of flue gas, waste of heat energy, etc. Condensation effect, effect of reducing investment amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

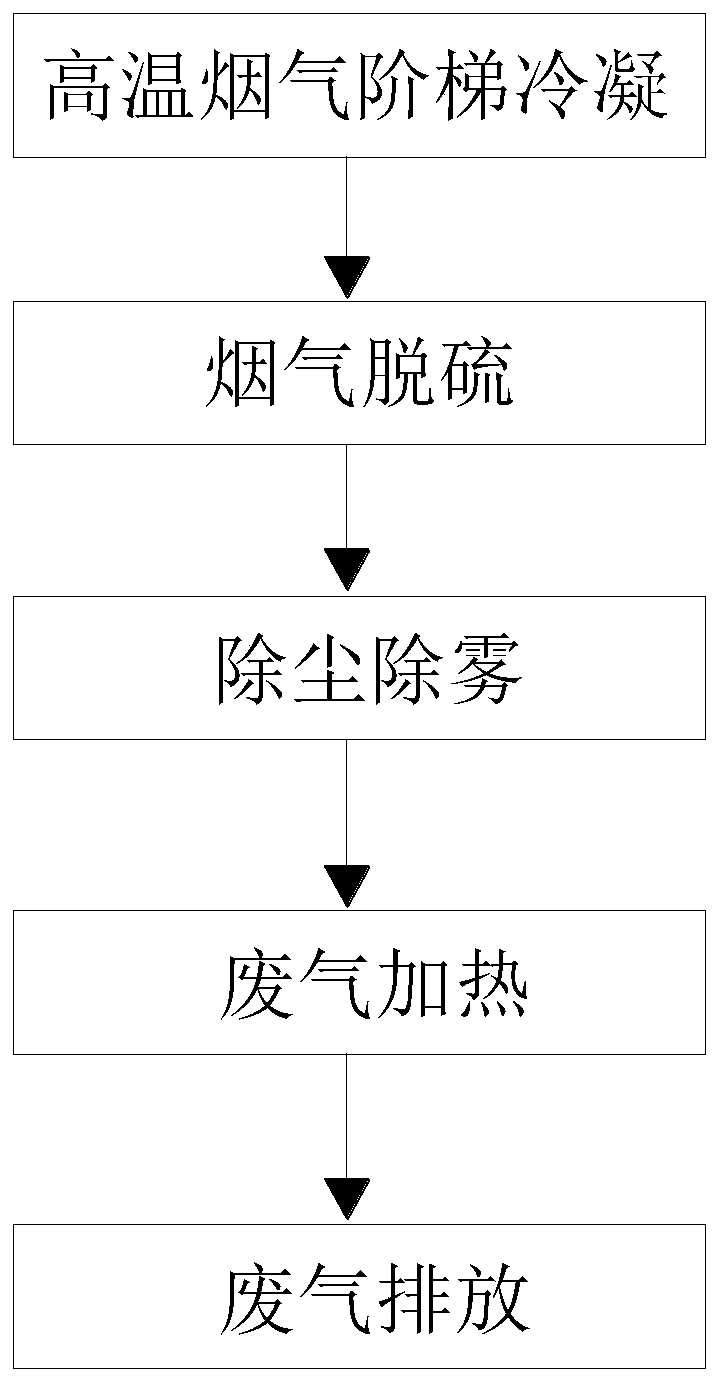

[0061] like figure 1 Shown, a kind of flue gas dewhitening method that improves thermal energy utilization rate, comprises the following steps:

[0062] S1: Stepwise condensation of high-temperature flue gas. The condenser is divided into a high-temperature chamber and a low-temperature chamber. The flue gas enters the high-temperature chamber and the low-temperature chamber in turn to condense. The cold water absorbs heat through the heat exchanger, and the steam condenses to achieve stepwise cooling;

[0063] S2: Flue gas desulfurization. The flue gas condensed by S1 enters the desulfurization tower. There are multi-layer desulfurization slurry spray devices distributed up and down inside the desulfurization tower. The acidic flue gas flows upward from the bottom and reversely contacts with the sprayed alkaline desulfurization slurry. Chemical neutralization reaction, the sulfurous acid generated falls into the bottom of the desulfurization tower for recycling;

[0064] S3:...

Embodiment 2

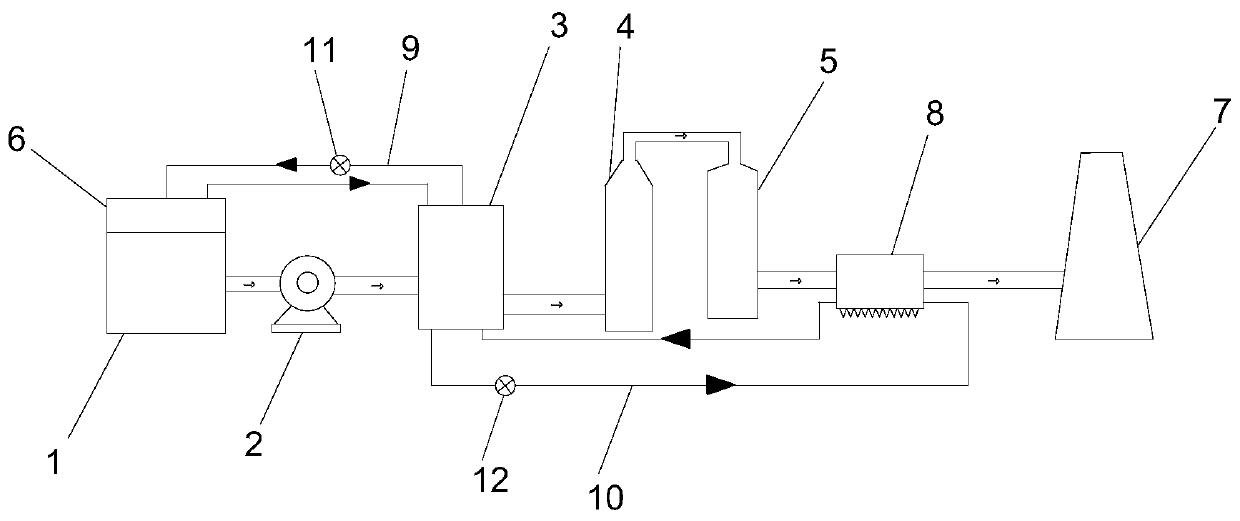

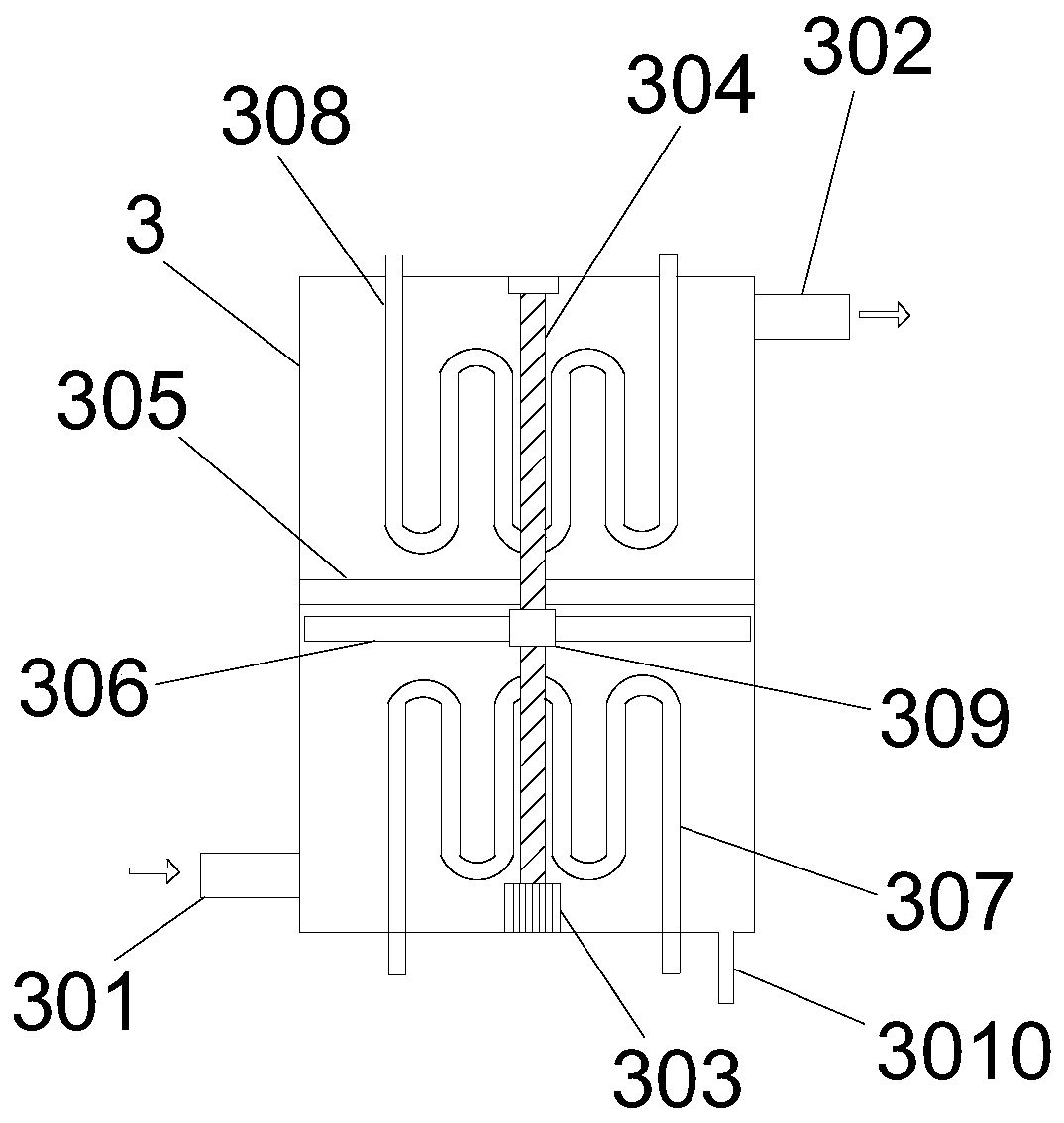

[0082] like Figure 1-6 As shown, the difference from Embodiment 1 is that the condenser 3 adopts segmental condensation, and the movable baffle 306 is controlled by the motor 303, thereby controlling the effective area of ventilation. When the movable baffle 306 and the fixed baffle 305 are composed When it is a circle, the ventilation area is 0. At this time, it can effectively prolong the time that the high-temperature gas stays inside the condenser 3, further improve the condensation effect, make the flue gas release heat completely, and achieve the purpose of efficient recovery of heat energy; the flue gas is condensed The time that device 3 stays is t (unit is s), and the effective area of ventilation is S (unit is m 2 ); then the flue gas heat energy recovery efficiency μ satisfies the following relationship:

[0083]

[0084]

[0085] In the above formula, α is a relational factor with a value range of 0.357-5.859; π is the circumference ratio, and d is the ...

Embodiment 3

[0088] like Figure 1-6 As shown, the difference from Embodiments 1 and 2 is that the particle diameter of the particulate matter in the flue gas satisfies:

[0089] D=(μV 0 h) 1 / 2 / ρWLT;

[0090] Where D is the particle diameter m of smoke particles, μ is the air viscosity Pa s, v 0 is the initial flow velocity m / s of the flue gas entering the dust and mist removal device, H is the height m of the dust and mist removal device, and ρ is the flue gas density mg / m 3 , W is the width m of the dust and mist removal device, and L is the length m of the dust and mist removal device.

[0091] v 0 The range of value is 6m / s~15m / s.

[0092] When the particle diameter of the particle meets the requirements of the above formula, the dust removal effect is the best; the particle in the flue gas settles to 5mg / m 3 Below, the water content is reduced to less than 15%, which meets the ultra-low emission standard of dust, improves the utilization of heat energy, and has a good dewhiten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com