Start-up method of dewatering capacity-enlarging start-up monotube boiler near steam heating boilers

A technology for heating boilers and once-through boilers, which is applied to feed water heaters, steam generation methods using heat carriers, lighting and heating equipment, etc. Problems such as the limitation of steam temperature, etc., to eliminate the loss of ventilation and heat dissipation, shorten the oil feeding time, and shorten the oil feeding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

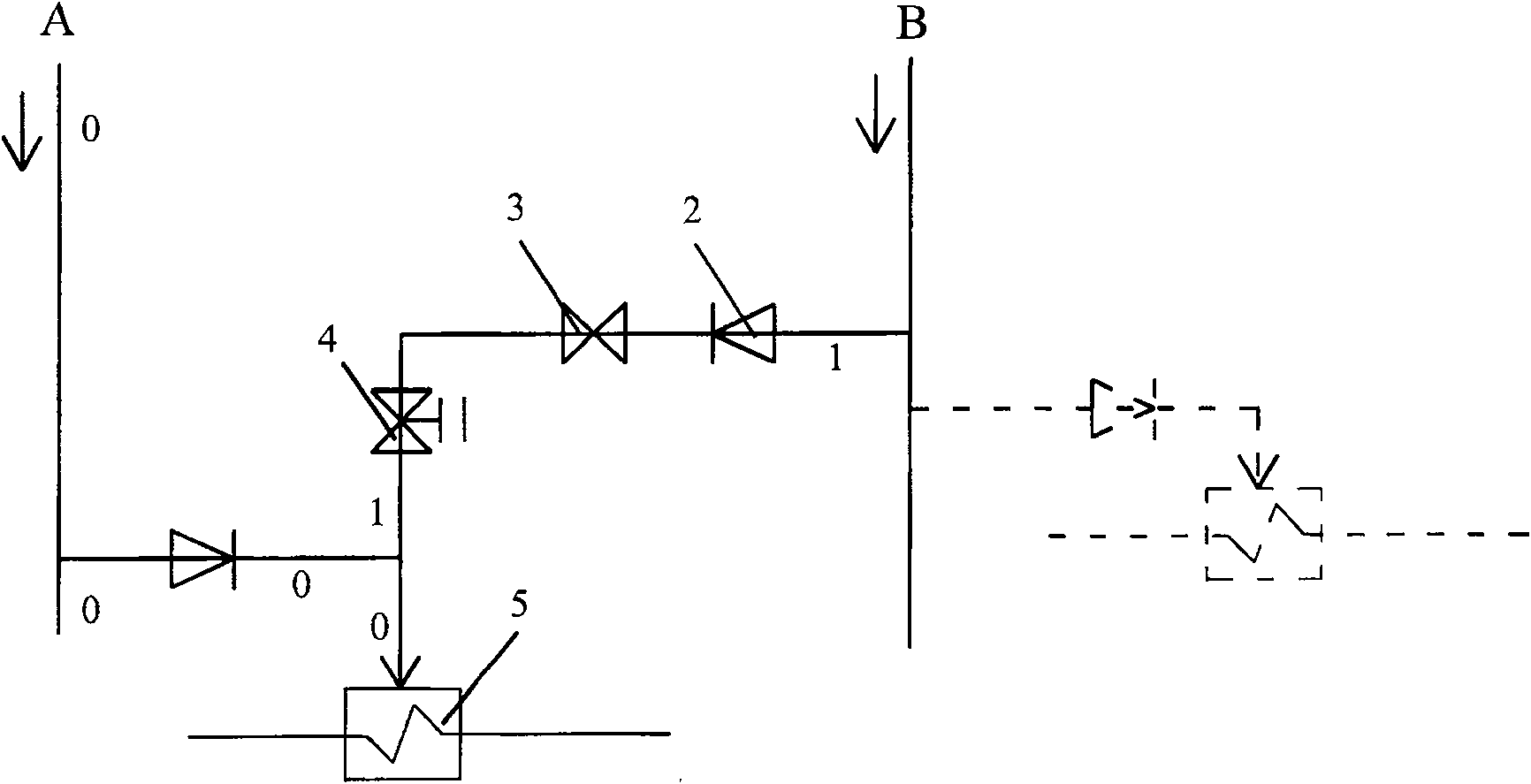

[0030] Such as figure 1 As shown, the schematic diagram of the system principle of the method for starting the heating of adjacent steam in the present invention. Wherein, the heating steam from another source comes from the unit B adjacent to the unit A to be started, and the steam pressure is 6 MPa. figure 1 The middle line 0 represents the original pipeline of unit A, the dotted line indicates the system of unit B, the line leading from unit B to the high-pressure heater 5 of unit A is the heating steam pipeline 1, and the pipeline 1 is equipped with check valve 2, stop valve 3 and Regulating valve 4, valve 2 is used to prevent the extraction steam of unit A from being poured back to B, valve 3 is used to input and cut off heating steam from other sources, and valve 4 is used to adjust the steam flow and pressure entering the high-pressure heater of unit A.

[0031] When the unit A is started in a very hot state, the method of the present invention comprises the following ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com