System and method for realizing zero emission of desulfurization waste water by denitrifying wide negative charges and utilizing waste heat

A technology of desulfurization wastewater and zero discharge, applied in chemical instruments and methods, separation methods, descaling and water softening, etc., can solve the problems of lower boiler exhaust gas temperature, lower boiler inlet air temperature and efficiency, etc., to achieve increased smoke Humidity, reduce emissions, and facilitate the effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

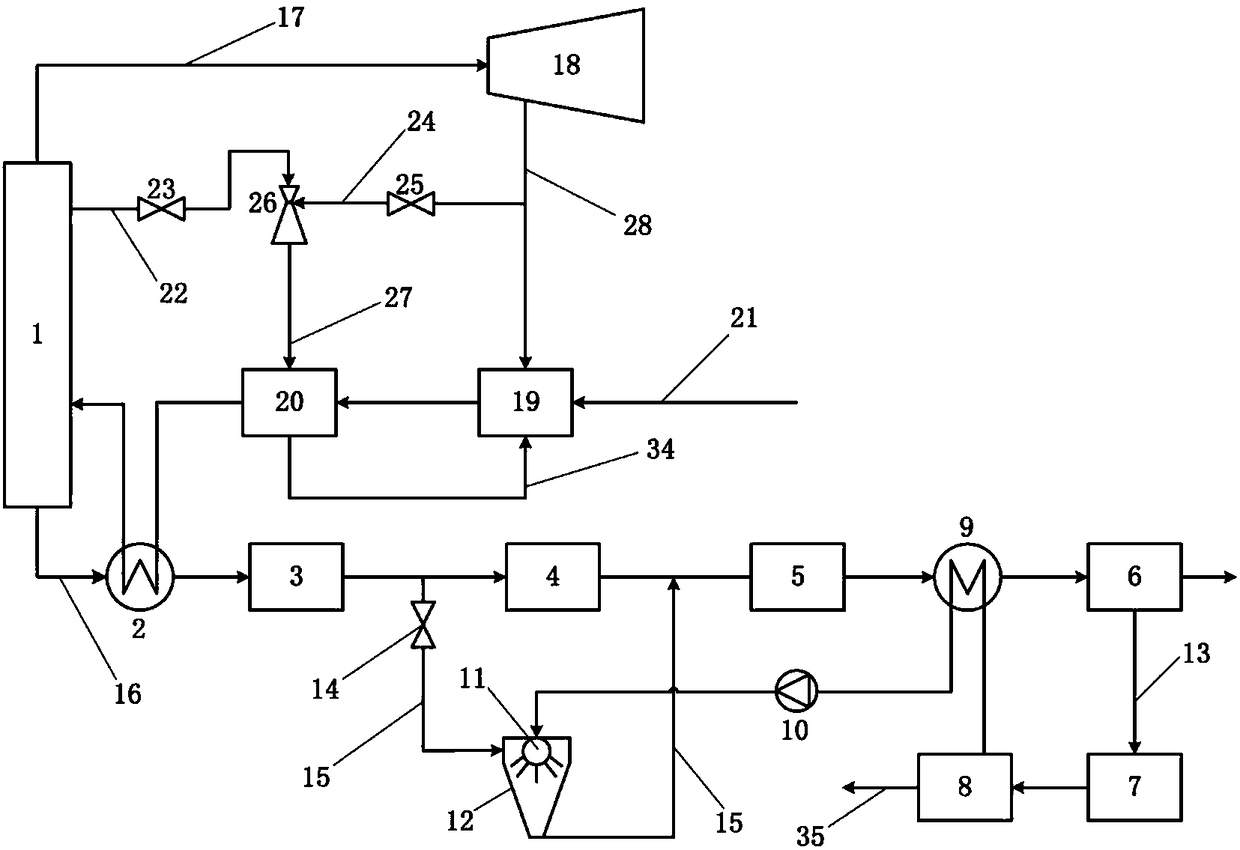

[0043] Such as figure 1 As shown, a desulfurization waste water zero discharge system for wide-load denitrification and waste heat utilization includes boiler 1, economizer 2, SCR denitrification device 3, air preheater 4, electrostatic precipitator 5, The desulfurization tower 6, wherein the economizer 2 is connected to the water supply pipeline 21, and the water supply pipeline 21 is provided with a No. The room is also provided with a No. 0 high drain pipeline 34 connected in parallel with the water supply pipeline. The desulfurization waste water zero discharge system also includes a steam turbine 18 connected to the boiler through a main steam pipeline 17; it also includes a feed water recovery subsystem and an air preheater bypass flue evaporation subsystem.

[0044] The feed water heating subsystem includes an ejector steam pipe 22, an ejected steam pipe 24, and an ejector 26. The outlets of the ejected steam pipe 22 and the ejected steam pipe 24 are respectively conne...

Embodiment 2

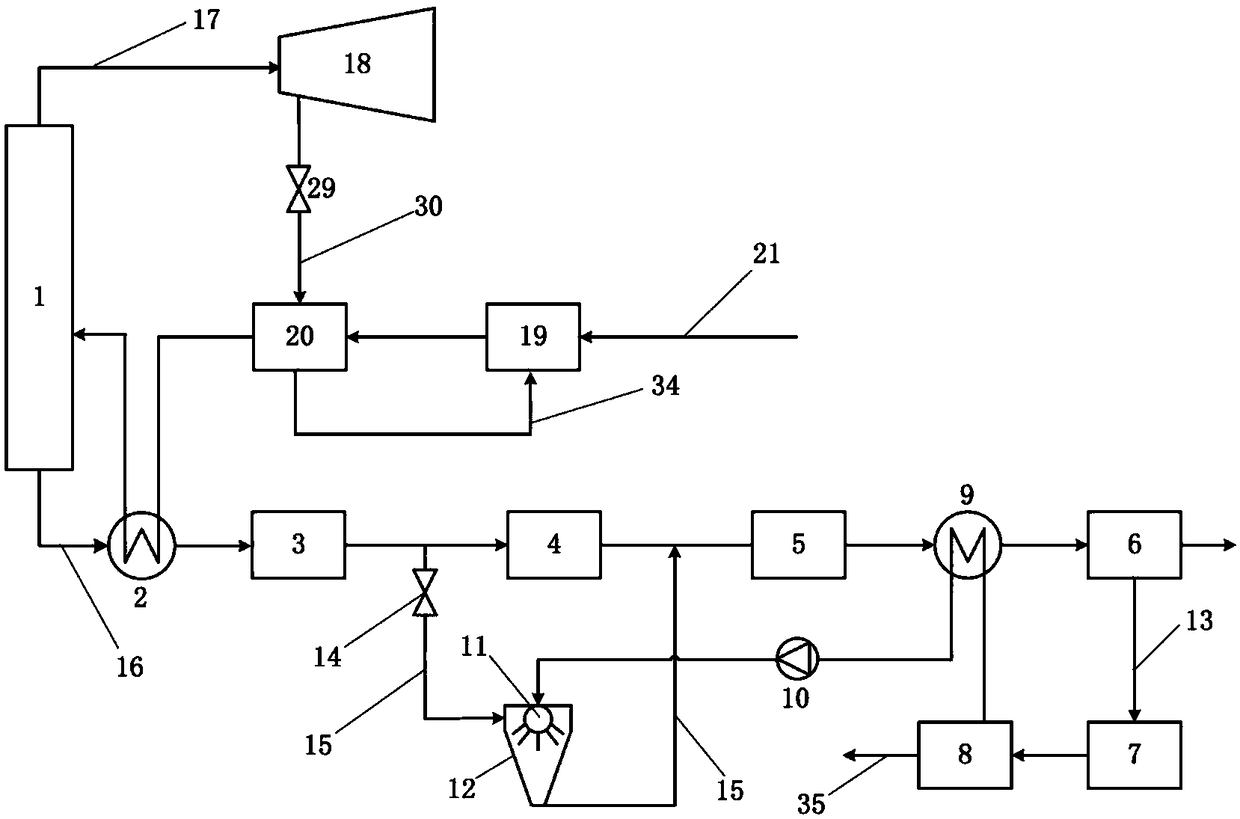

[0057] Such as figure 2 As shown, it is another wide-load denitrification and waste heat utilization zero-discharge system for desulfurization wastewater. This embodiment is different from Embodiment 1 only in the water supply and heat recovery subsystem, and the similarities will not be repeated. The differences are:

[0058] The feed water heating sub-system includes a high-pressure steam pipeline A30, the inlet of the high-pressure steam pipeline A30 is connected to the high-pressure cylinder of the steam turbine 18, and the outlet of the high-pressure steam pipeline A30 is connected to No. There is a high-pressure steam pipeline valve A29 with an adjustable opening.

[0059] The method of this embodiment is different from that of Embodiment 1 only in "step 1", and the similarities will not be described again. The difference is:

[0060] Step 1. When the load of the unit is reduced, open the high-pressure steam pipeline valve A29, and control the steam flow by adjusting t...

Embodiment 3

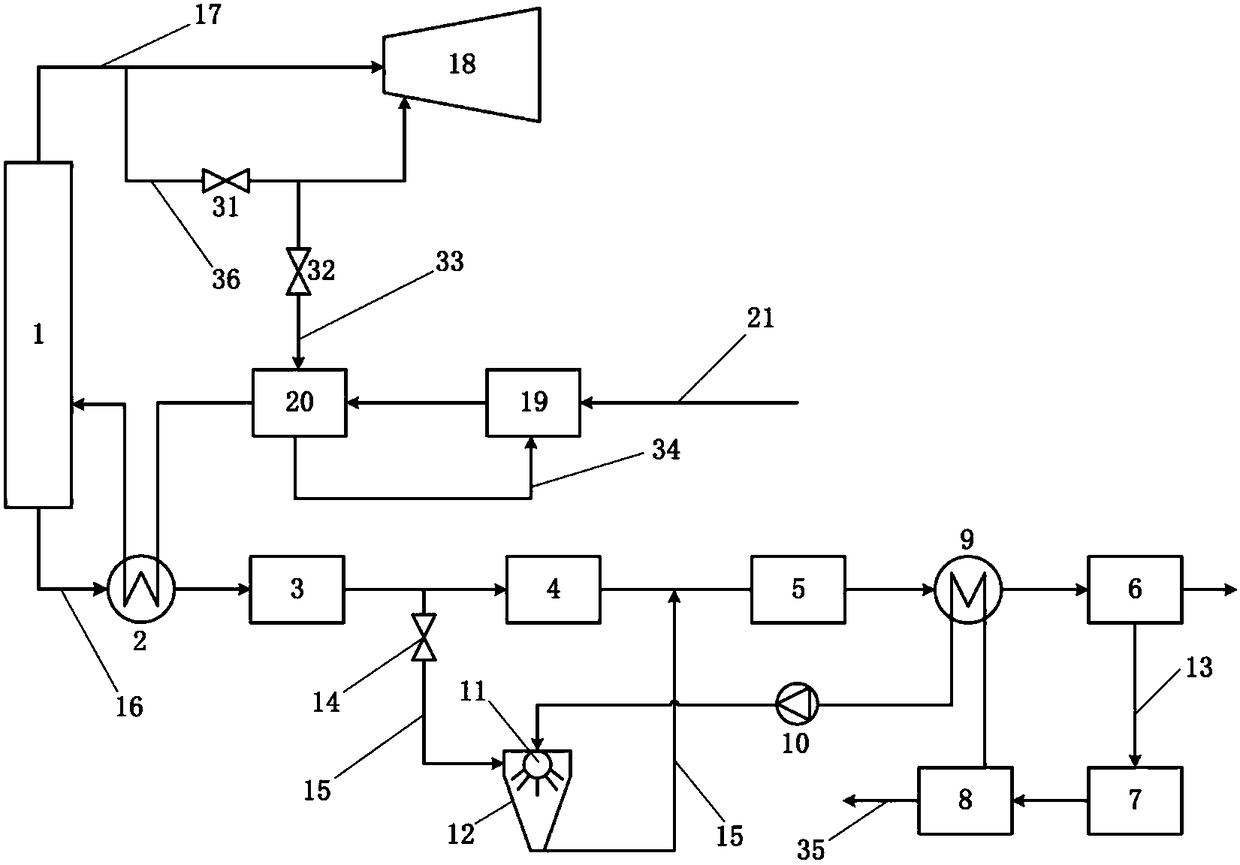

[0062] Such as image 3 As shown, it is another wide-load denitrification and waste heat utilization zero-discharge system for desulfurization wastewater. This embodiment is different from Embodiment 1 only in the water supply and heat recovery subsystem, and the similarities will not be repeated. The differences are:

[0063] The feed water heating sub-system includes a high-pressure steam pipeline B33, the inlet of the high-pressure steam pipeline B33 is connected to the supplementary steam pipeline 36, and the outlet of the high-pressure steam pipeline B33 is connected to the No. The inlet of the pipeline 36 is connected with the main steam pipeline 17, and the outlet of the supplementary steam pipeline 36 is connected with the steam turbine 18; the supplementary steam pipeline 36 and the high-pressure steam pipeline B33 are respectively provided with an adjustable opening steam supplement regulating valve 31 and The high-pressure steam pipeline valve B31 ; the connection b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com