Production method of homogeneous petroleum needle coke

A technology of needle coke and petroleum, which is applied in the petroleum industry, coking ovens, coking carbonaceous materials, etc., can solve the problems that the quality uniformity and strength of needle coke cannot be improved, and achieve the effect of improving the anti-wear index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

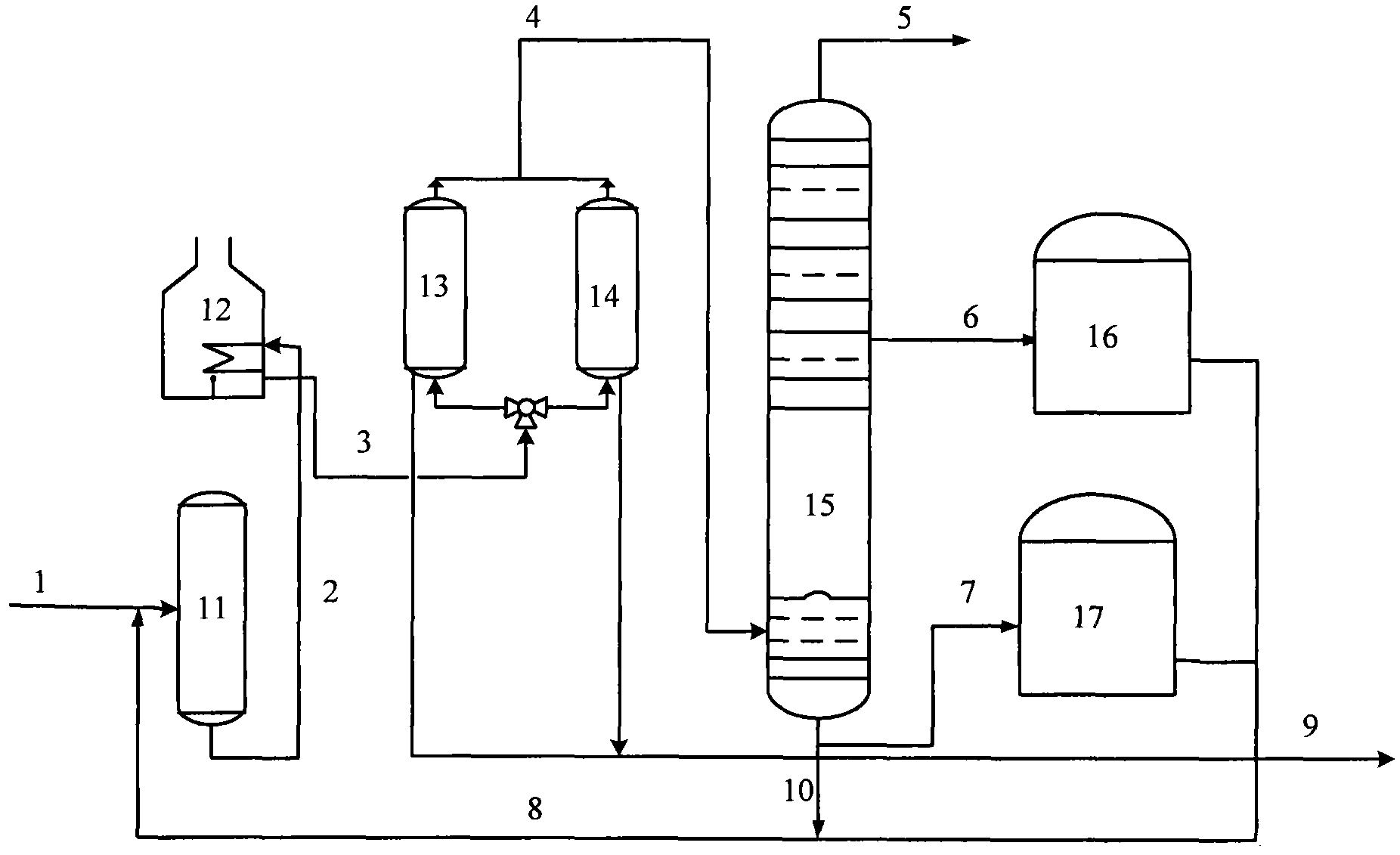

Method used

Image

Examples

Embodiment 1

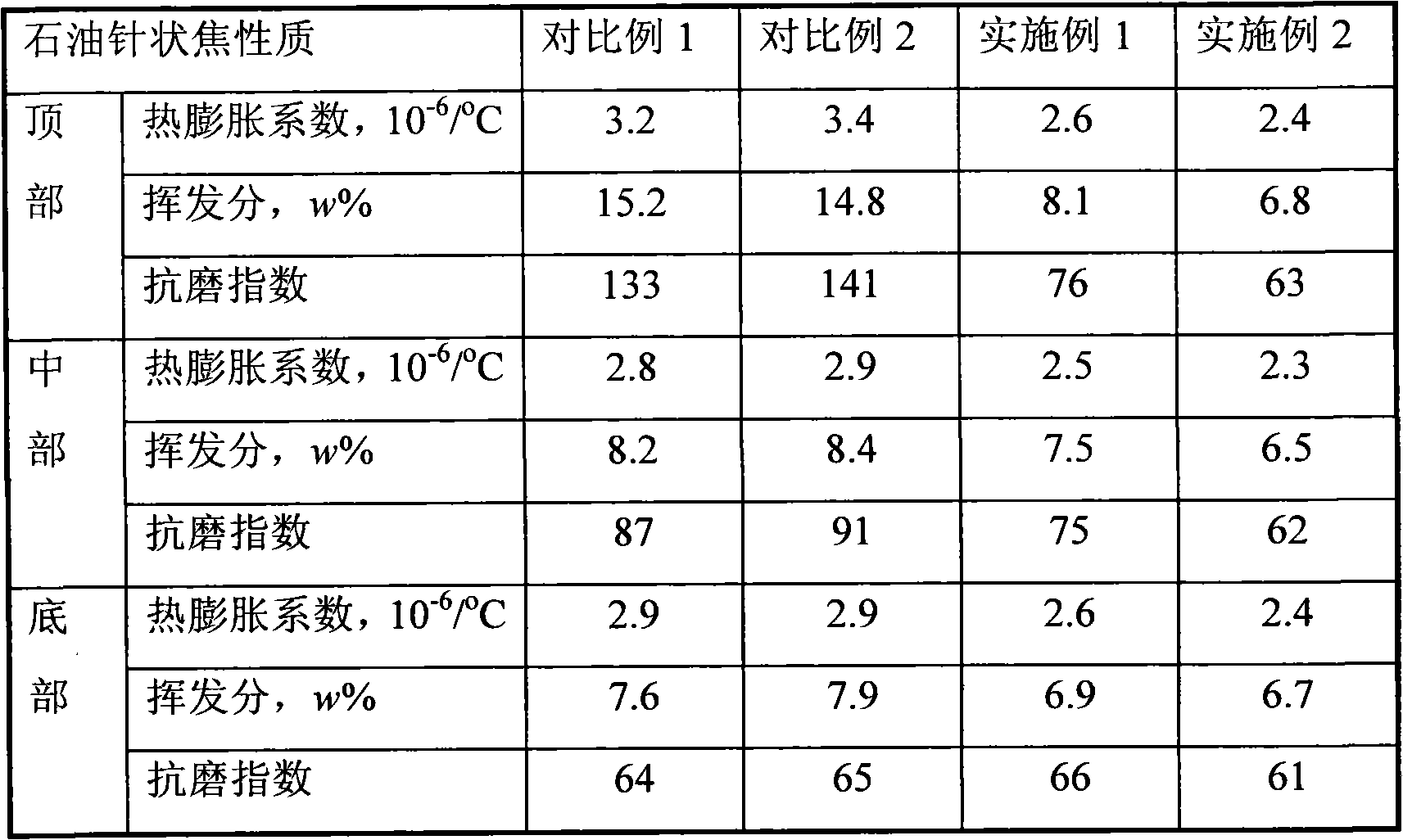

[0037] Example 1 illustrates the effect of delayed coking in producing needle coke by the method provided by the present invention.

[0038] Using the same device and raw materials as in Comparative Example 1, the top pressure of the coking tower is 0.4MPa, and the coking cycle of coking is 32 hours. According to the method provided by the present invention, the coking feed in step (1) is the coking raw material feed, and the coking heating The furnace outlet temperature is 420°C, and the temperature of the material in the coking tower is 410°C. The duration of step (1) is 9.6 hours, which is 30% of the entire coking cycle. Step (2) The coking feed is fresh feed and heavy distillate oil from the fractionation tower, the circulation ratio is 1, the temperature at the outlet of the coking heating furnace is raised to 480° C. at a rate of 8° C. / hour, and then kept at a constant temperature. Step (2 ) lasts for 11.2 hours, which is 35% of the entire coke generation cycle. Step (...

Embodiment 2

[0043] Example 2 illustrates the effect of the method provided by the present invention on the production of needle coke by delayed coking.

[0044] Using the same device and raw materials as in Comparative Example 1, the pressure at the top of the coking tower is 0.4MPa, and the coking cycle of coking is 44 hours. The operation is carried out according to the method provided by the present invention, that is, the coking feed in step (1) is the coking raw material, and the coking heating furnace exits The temperature is 450° C., and the duration of step (1) is 24.6 hours, accounting for 60% of the entire coke generation cycle. Step (2) The coking feed is fresh feed and heavy distillate oil from the fractionation tower, the circulation ratio is 1, the coking heating furnace outlet temperature is raised to 480°C at a heating rate of 3.5°C / hour, and then kept at constant temperature, step (2 ) duration of 8.2 hours, accounting for 20% of the entire coke cycle. Step (3) The cokin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com