Pulse type power mode LED voltage-current-junction temperature characteristic testing device

A pulsed current and power type technology, applied in the field of light-emitting diode characteristic testing devices, can solve the problems of measurement error, affecting the signal-to-noise ratio of the test signal, etc., and achieve the effects of improving accuracy, reducing self-heating effect and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

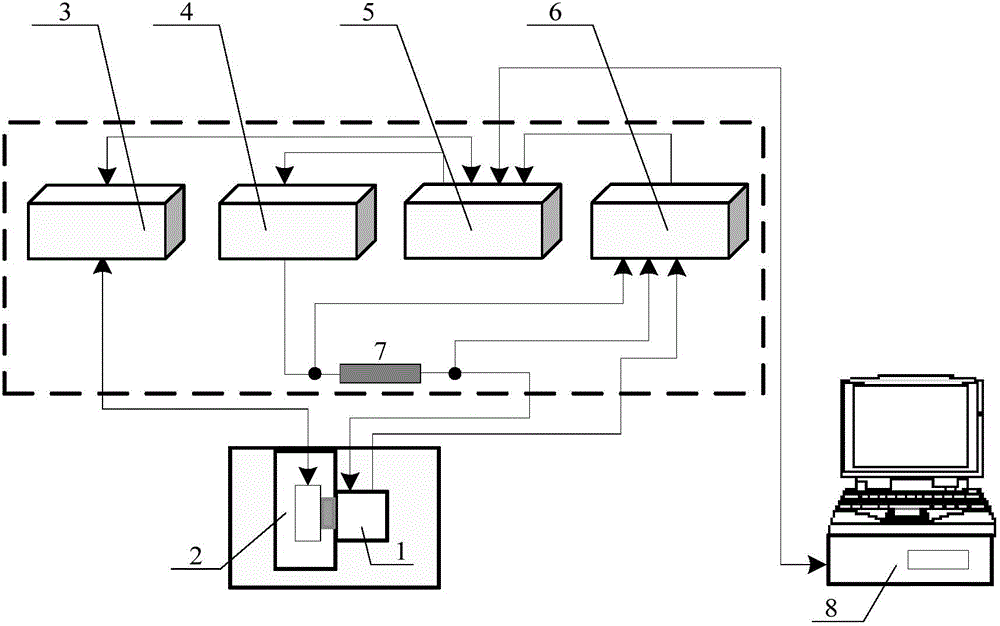

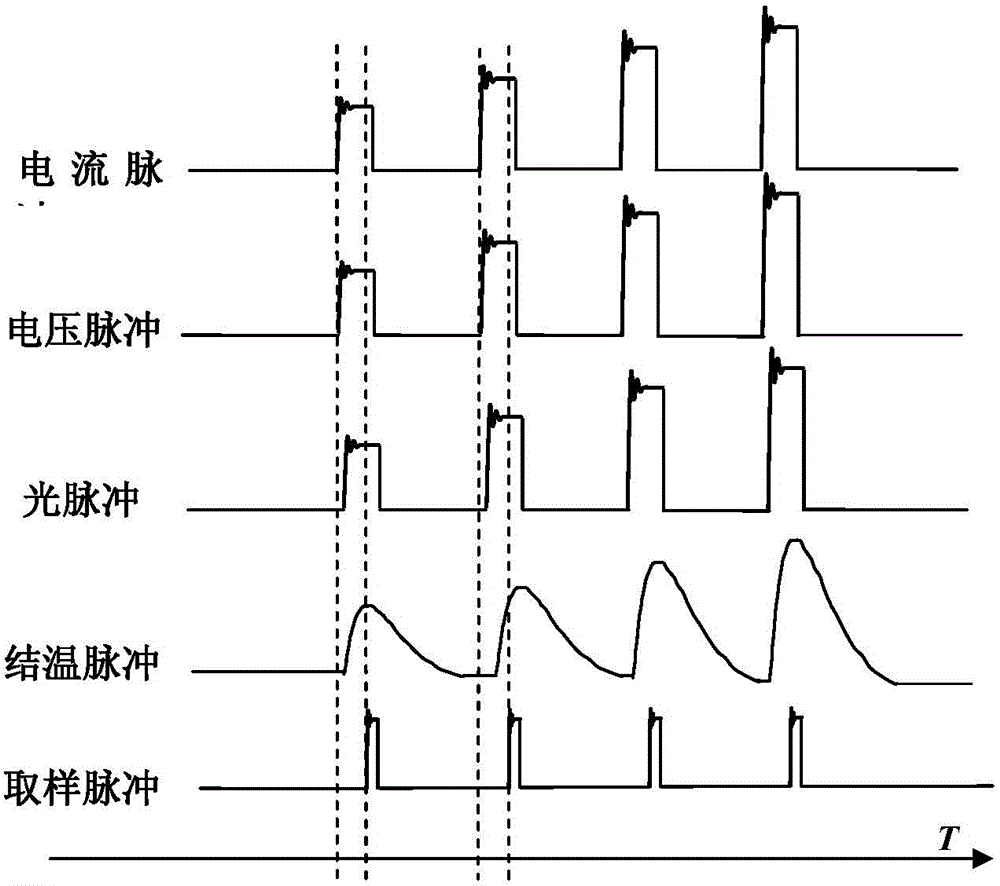

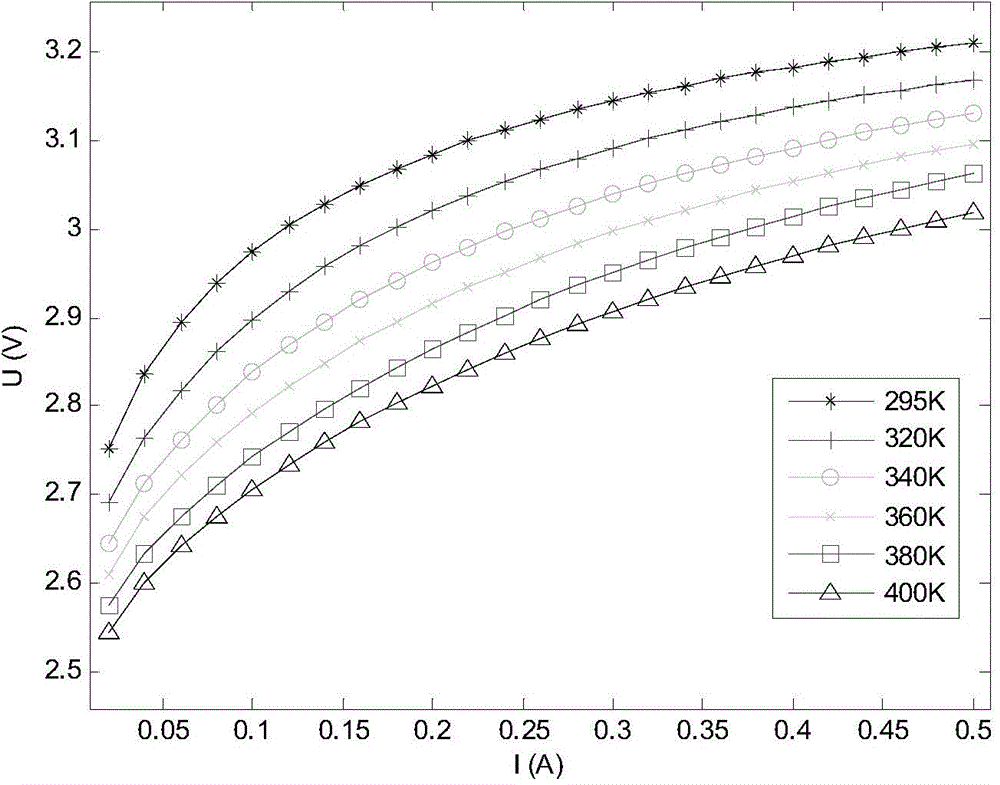

[0018] see Figure 1~3 , The embodiment of the present invention is provided with a fixture 2, a temperature control module 3, a pulse current source 4, a digital control module 5, a data acquisition module 6, a precision sampling resistor 7, and a computer 8.

[0019] The LED1 to be tested is installed on the fixture 2, the temperature control module 3 is connected with the digital control module 5 for setting temperature and feedback temperature, the temperature control module 3 is connected with the fixture 2 for heating or cooling and monitoring temperature, the The pulse current source 4 is connected to the digital control module 5 for setting pulse parameters, the pulse current source 4 is connected to one end of the precision sampling resistor 7, and the other end of the precision sampling resistor 7 is connected to the LED1 to be measured; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com