Drying cooling device and drying cooling system for energetic materials

A drying, cooling and drying technology, which is applied in the direction of drying solid materials, heating devices, drying, etc., can solve the problems of toxicity of small molecules, difficulty in deriving excess heat, easy combustion or explosion, etc., and achieve the effect of strengthening the drying and cooling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

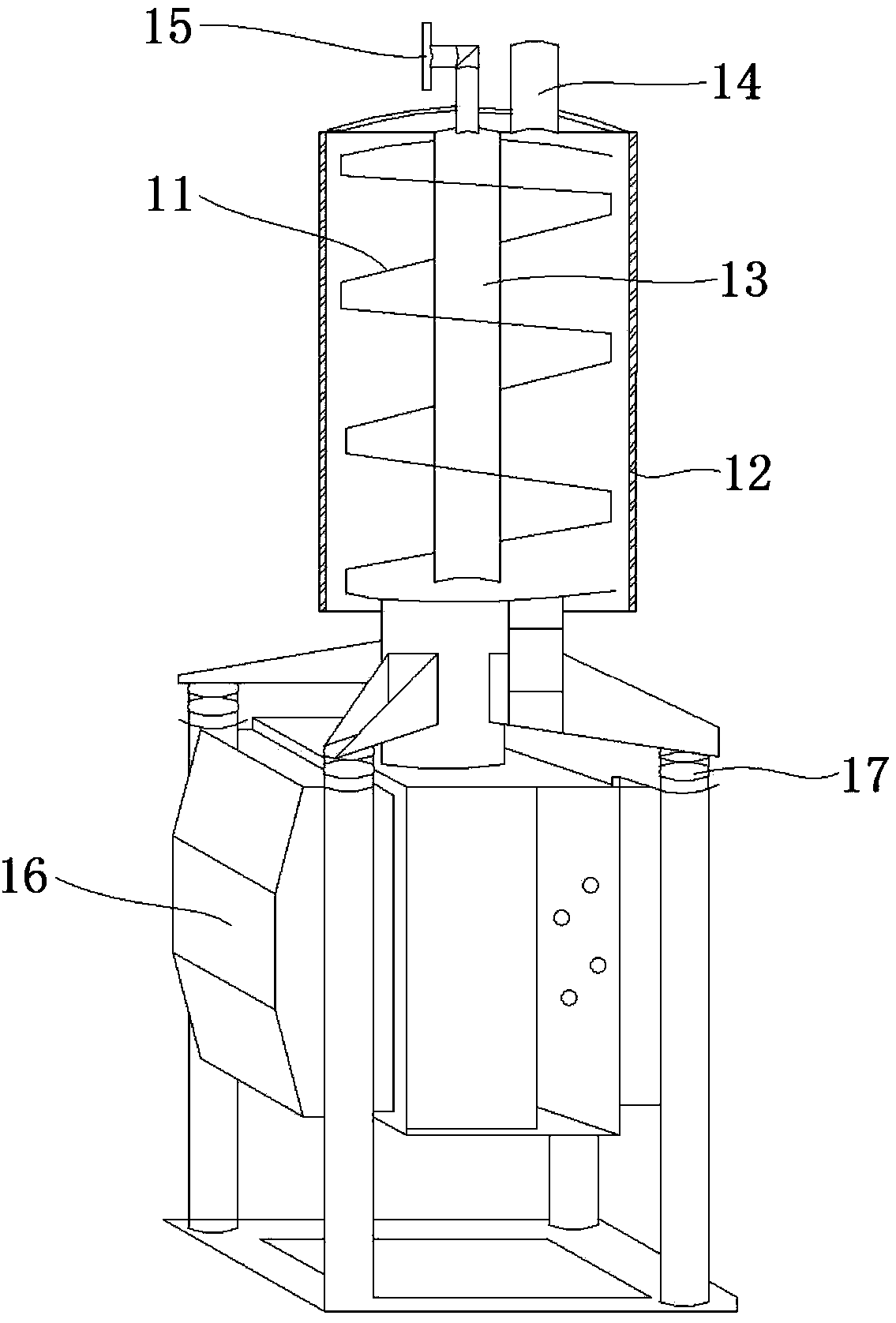

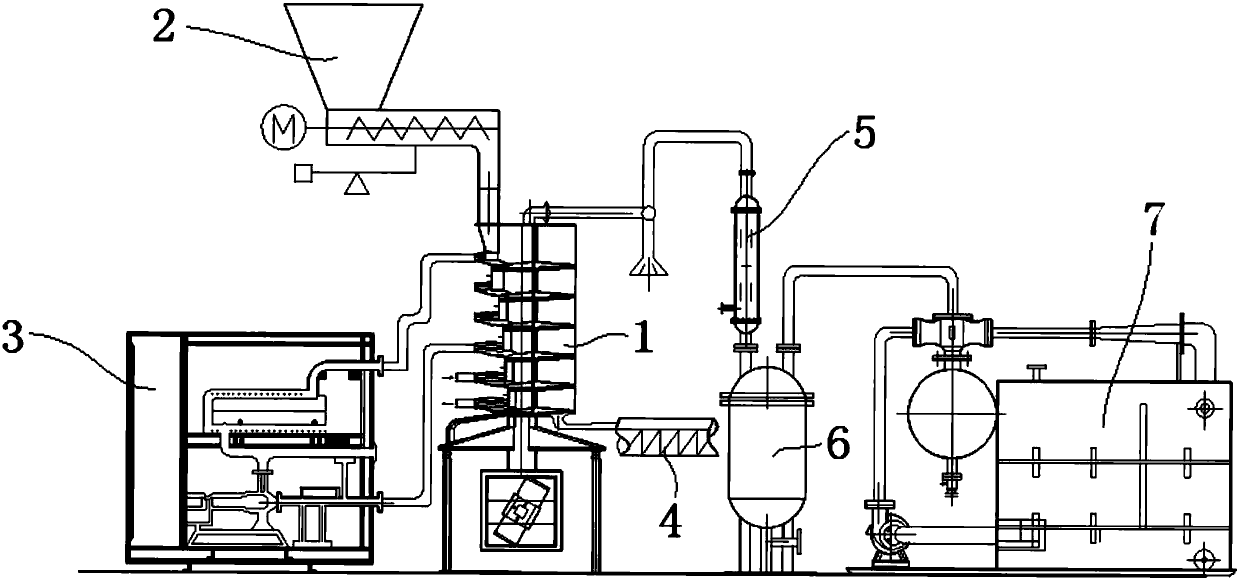

[0040] This embodiment is a specific dry cooling system. refer to figure 2 , the whole system is composed of water heater 3, twin-screw automatic feeder 2, drying and cooling device 1 of the present invention, automatic belt discharge conveyor 4, tube condenser 5, buffer tank 6, and water jet vacuum pump 7.

[0041] Start the water pump before drying, set the heating temperature of the circulating deionized water, start the power supply of the control cabinet, turn on the water heater, and the circulating pure water enters the spiral coil cavity through the pipeline. There are six layers of spiral coils, of which the upper four layers are The drying plate, the lower two layers are cooling plates, the hot water inlet pipe and the outlet pipe are respectively connected to the first and fourth stage coils, the cooling water is tap water at normal temperature, and the inlet pipe and outlet pipe are respectively connected to the fifth and fourth stage coils. The sixth-stage spira...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com