Heat pump distillation apparatus and process for diethyl carbonate

A diethyl carbonate, heat pump rectification technology, applied in the direction of organic carbonate preparation, organic chemistry, etc., can solve the problems of large cooling engineering, high energy consumption, etc., to reduce energy consumption, save energy consumption, and reduce boiler heat consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

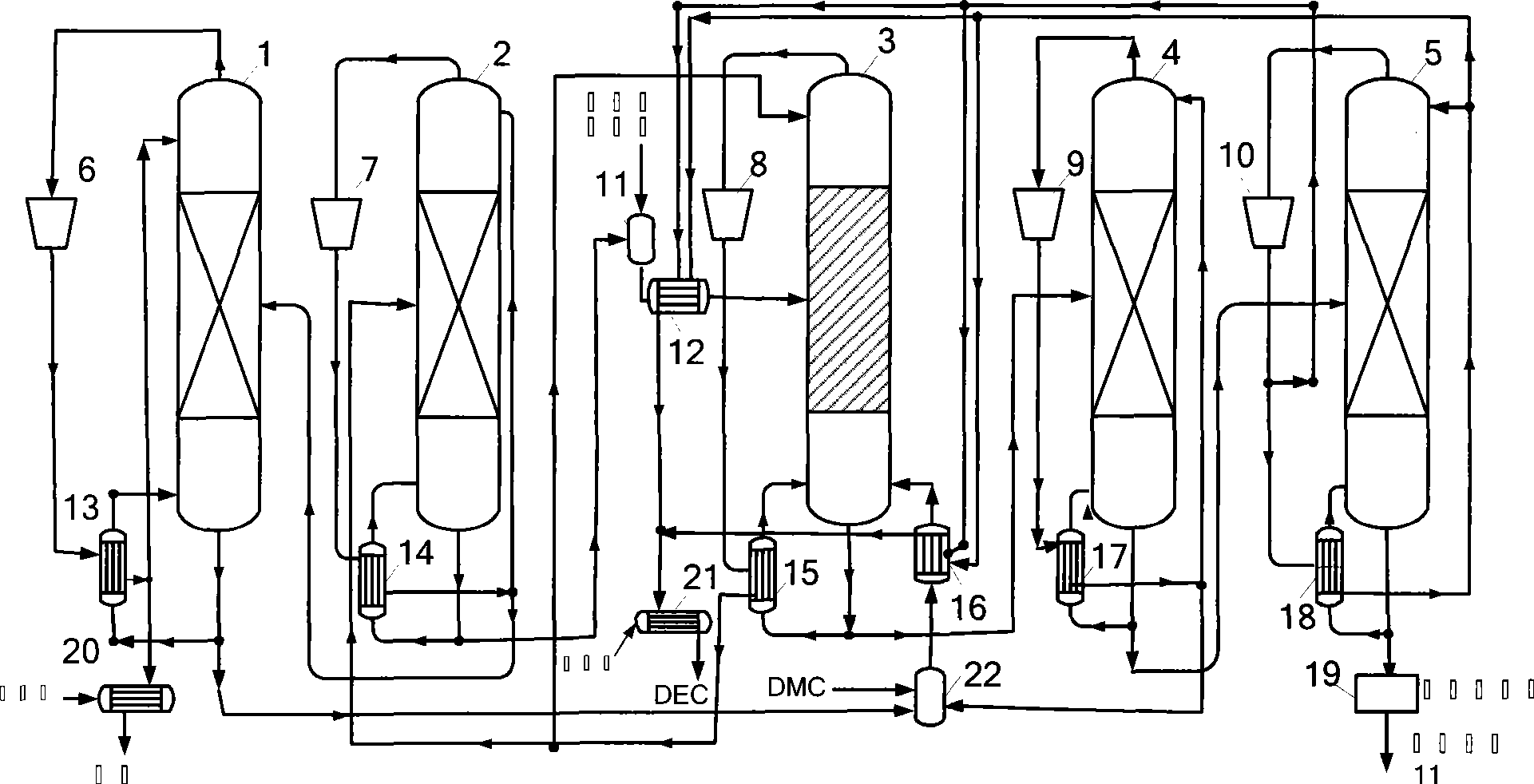

[0020] The device structure principle and process flow of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0021]Referring to accompanying drawing, diethyl carbonate heat pump rectification device comprises reactive rectification tower 3, heavy component rectification tower 4, light component rectification tower 2, dimethyl carbonate separation tower 1 and diethyl carbonate rectification tower 5. The steam outlets of the top materials of the above five towers are respectively connected to the suction sides of compressor 8, compressor 9, compressor 7, compressor 6 and compressor 10 through pipelines; the exhaust side of compressors are respectively connected through pipelines It is communicated with the hot-side inlet ports of the reboilers 15, 17, 14, 13, and 18 at the bottom of the respective rectification towers; The upper return ends of 3, 4, 2, 1, and 5 are connected, and the exhaust side of the compressor 6 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com