Multi-stage heat recovery compound dehumidification fresh air air handler

A heat recovery and processor technology, applied in the direction of shielding with air flow, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of increasing regeneration energy consumption, high regeneration temperature, and increased energy consumption, etc. Achieve the effect of reducing cooling energy consumption, reducing regeneration temperature, and reducing heating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

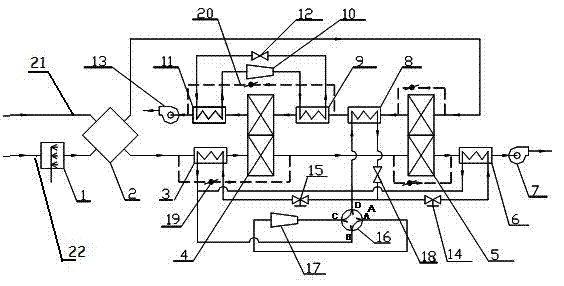

[0033] Such as Figure 5 As shown in the winter operation mode, the evaporative cooler 1, the pre-cooling dehumidifier 3, the drying runner 4, the sensible heat recovery runner 5, and the high-temperature heat pump heat recovery system will all stop running.

[0034] The air treatment process is as follows: outdoor fresh cold air enters the plate heat exchanger 2 to exchange heat with the indoor exhaust air with a higher temperature from the building, and the temperature rises. The preheated fresh air enters the air supply temperature regulator 6 through the bypass pipe, is heated to the air supply temperature by the high-temperature refrigerant vapor from the low-temperature heat pump, and then is sent into the room through the air supply fan 7.

[0035] The building exhaust air treatment process is: the building exhaust air passes through the plate heat exchanger 2, transfers energy to the fresh air, lowers the temperature, and then enters the low-temperature heat pump heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com