Device and technique for purifying and processing titanium white waste acid

A technology for purification and treatment of titanium dioxide waste acid, which is applied in the direction of sulfur trioxide/sulfuric acid, etc., can solve the problems of difficult removal of nanometer or submicron titanium dioxide particles, high cost and impossibility, so as to reduce the burden of separation, reduce the load, The effect of increasing continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

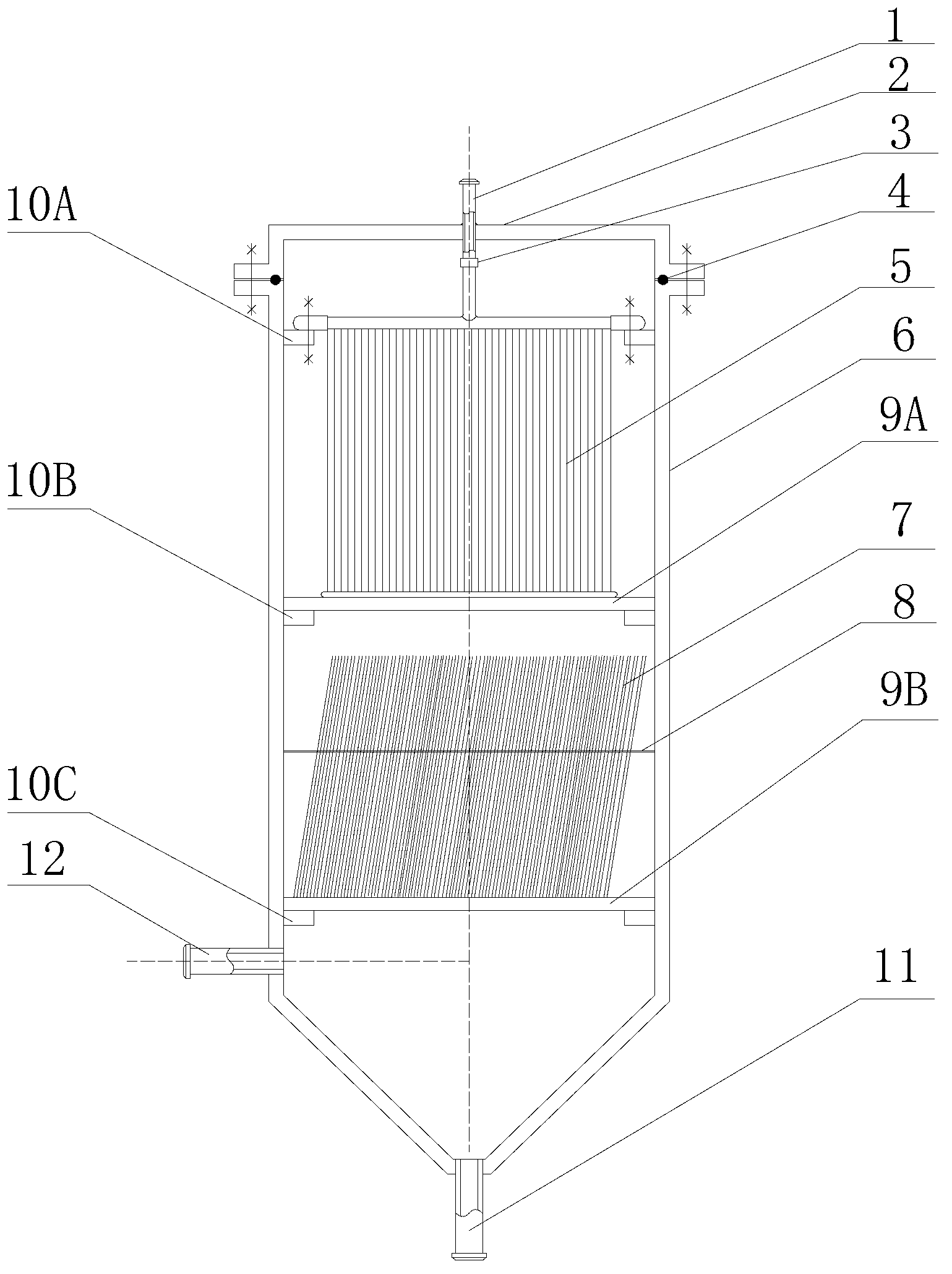

[0017] The structural representation of the titanium dioxide waste acid purification treatment device provided by the present invention is as follows figure 1 As shown: Titanium white waste acid purification treatment device, consists of a separation tank, a sealing cover, a clear liquid outlet, a connector, a sealing ring, a filter element, a sloping plate, a sloping plate partition, a first porous plate, a second porous plate Plate, the first support ring, the second support ring, the third support ring, the liquid outlet and the feed liquid inlet; the separation tank and the sealing cover are fixed by a sealing ring through bolts, and a clear liquid outlet is installed in the center of the top of the sealing cover. The water outlet; the upper part of the separation tank is cylindrical, the lower part is a conical structure, the conical bottom is connected with a liquid discharge port, the junction of the cylinder and the conical shape is provided with a feed liquid inlet, an...

Embodiment 2

[0019] The device structure of this embodiment is the same as that of Example 1, wherein the preferred 0.1 μm aperture of the filter core is made of polyethylene; the inclined plate material is polyethylene, and the distance between the inclined plates is 4 mm; the porous plate is polyethylene Plastic plate, the thickness of the porous plate is preferably 5cm, and the circular holes are evenly distributed on the porous plate, and the area of the holes is preferably 1cm 2 , the number of holes per square meter is 2000.

[0020] Pump the titanium white waste acid solution containing powder particles into the feed liquid inlet of the device, keep the pressure at 0.05MPa, the feed liquid enters the separation tank to form a swirling flow, and some particles above the millimeter scale directly sink, containing fine The granular liquid flows through the porous plate, and first settles through the inclined plate to remove most of the particles with a size of tens of microns, and th...

Embodiment 3

[0022] The structure of the device in this embodiment is the same as in Example 1, wherein the selected filter element has a pore size of 50 μm, and the material of the filter element is ceramics; the material of the inclined plates is polypropylene, and the distance between the inclined plates is 15 mm; the porous plate is ceramics with a thickness of 1 cm plate, 30 per square meter are distributed on the perforated plate with an area of 200cm 2 square hole.

[0023] Pump the titanium white waste acid solution containing powder particles into the feed liquid inlet of the device, keep the pressure at 0.5 MPa, and the feed liquid enters the separation tank to form a swirling flow, and some particles above the millimeter scale directly sink, containing fine The granular liquid flows through the porous plate, and first settles through the inclined plate to remove most of the particles with a size of tens of microns, and then is further filtered through the filter element to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com