Sulfonation waste mud treatment process

A waste mud and treatment process technology, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of polluting the ecological environment and ecological balance, failing to meet discharge standards, damage, etc. Achieve the effect of reducing the separation burden, good effect and optimized design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

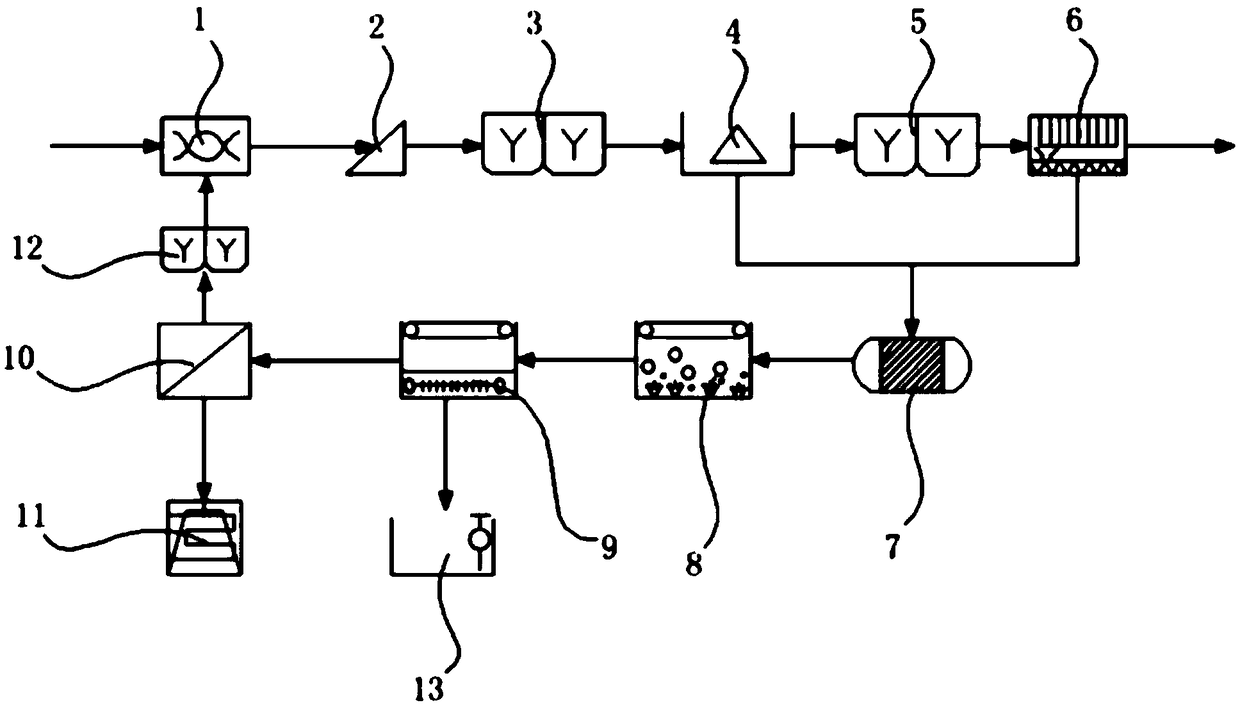

[0024] 1. A sulfonated waste mud treatment process, characterized in that it comprises the following steps,

[0025] 1) Send the sulfonated mud into the fluidization device 1 through the grabbing device, dilute the sulfonated mud with water in the ratio of 1:1 to 3 in the fluidization device 1, and then add an appropriate amount of biological surface cleaning agent to control the reaction The temperature is 30°C, and the fluidization reaction is 18 minutes;

[0026] 2) After the reaction is completed, the sulfonated mud is pumped into the screening device 2, and the fine sand in the sulfonated mud is removed;

[0027] 3) The sulfonated mud after the desanding operation enters the first homogeneous tank 3, and at the same time, an appropriate amount of polyaluminum chloride and sawdust xanthate are sequentially added to the first homogeneous tank 3 for homogeneous reaction;

[0028] 4) The homogeneously reacted sulfonated mud enters the centrifugal device 4 for solid-liquid se...

Embodiment 2

[0034] 1. A sulfonated waste mud treatment process, characterized in that it comprises the following steps,

[0035] 1) Send the sulfonated mud into the fluidization device 1 through the grabbing device, dilute the sulfonated mud with water in the ratio of 1:1 to 3 in the fluidization device 1, and then add an appropriate amount of biological surface cleaning agent to control the reaction The temperature is 40°C, and the fluidization reaction is 20 minutes;

[0036] 2) After the reaction is completed, the sulfonated mud is pumped into the screening device 2, and the fine sand in the sulfonated mud is removed;

[0037] 3) The sulfonated mud after the desanding operation enters the first homogeneous tank 3, and at the same time, an appropriate amount of polyferric sulfate and sodium diethyldithiocarbamate are sequentially added to the first homogeneous tank 3 for homogeneous reaction ;

[0038] 4) The homogeneously reacted sulfonated mud enters the centrifugal device 4 for sol...

Embodiment 3

[0044] 1. A sulfonated waste mud treatment process, characterized in that it comprises the following steps,

[0045] 1) Send the sulfonated mud into the fluidization device 1 through the grabbing device, dilute the sulfonated mud with water in the ratio of 1:1 to 3 in the fluidization device 1, and then add an appropriate amount of biological surface cleaning agent to control the reaction The temperature is 50°C, and the fluidization reaction is 22 minutes;

[0046] 2) After the reaction is completed, the sulfonated mud is pumped into the screening device 2, and the fine sand in the sulfonated mud is removed;

[0047]3) The sulfonated mud after the desanding operation enters the first homogenizing tank 3, and at the same time, in the first homogenizing tank 3, an appropriate amount of polyaluminum iron silicate and sodium diethyldithiocarbamate are added successively for homogenizing. qualitative response;

[0048] 4) The homogeneously reacted sulfonated mud enters the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com