Method for comprehensively recycling lead, zinc, tin and fluorite from tailings

A technology for tailings and fluorite, applied in the field of environmental protection treatment of tailings, can solve the problem of no economical and feasible method for recycling, and achieve the effects of reducing the burden of separation, comprehensively and effectively utilizing resources, and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A tailing sand contains 2.03% lead and zinc, 0.36% cassiterite and 15.22% fluorite.

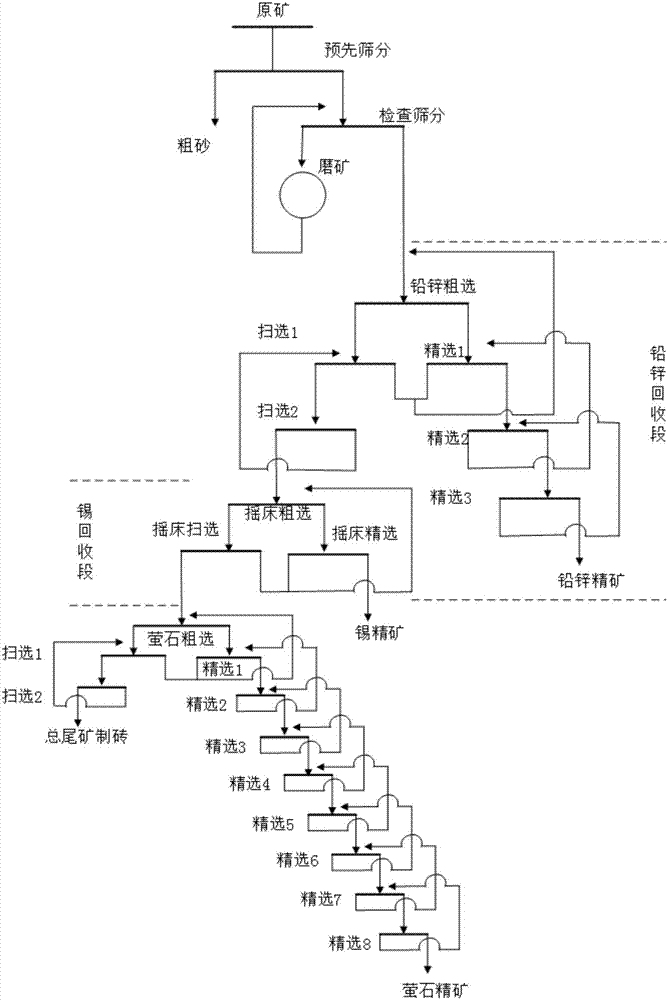

[0032] Adopt technology of the present invention, comprise the following steps:

[0033] (1) Firstly, the original tailings are pre-screened through 20 mesh, and the -20 mesh tailings are ground, and the ground to -200 mesh accounts for about 90% of the flotation;

[0034] (2) Use the flotation method to recover lead-zinc minerals by flotation, and adopt the process of one rough three fine two sweeps to recover the lead and zinc. The pharmaceutical system is as follows: copper sulfate is the activator, butyl xanthate is the collector Oil is the foaming agent, the amount used in the rough selection is activator 150g / t, collector 100, foaming agent 20g / t, the three selections are all blank flotation, no reagent is added; the first sweep: collector 60g / t, foaming agent 5g / t, second sweep: collector 20g / t, foaming agent 5g / t;

[0035] (3) For the flotation tailings, the cassiterite in it...

Embodiment 2

[0040] A certain tailings contains 2.52% lead and zinc, 0.72% tin and 23.36% fluorite.

[0041] Adopt technology of the present invention, comprise the following steps:

[0042] (1) Firstly, the original tailings are pre-screened through 20 mesh, and the -20 mesh tailings are ground, and the ground to -200 mesh accounts for about 90% of the flotation;

[0043] (2) Use the flotation method to recover lead-zinc minerals by flotation, and adopt the process of one rough three fine two sweeps to recover the lead and zinc. The pharmaceutical system is as follows: copper sulfate is the activator, butyl xanthate is the collector Oil is the foaming agent, the amount used in the rough selection is 180g / t activator, 110g / t collector, 25g / t foaming agent, and 70g / t collector, 8g / t foaming agent, Secondary sweeping: collector 30g / t, foaming agent 8g / t;

[0044] (3) For the flotation tailings, use a shaker to recover the cassiterite in it by sweeping, roughing, refining, and cleaning. The...

Embodiment 3

[0049] A certain tailings contains 2.21% lead and zinc, 0.53% tin and 20.15% fluorite.

[0050] Adopt technology of the present invention, comprise the following steps:

[0051] (1) Firstly, the original tailings are pre-screened through 20 mesh, and the -20 mesh tailings are ground, and the ground to -200 mesh accounts for about 90% of the flotation;

[0052] (2) Use the flotation method to recover lead-zinc minerals by flotation, and adopt the process of one rough three fine two sweeps to recover the lead and zinc. The pharmaceutical system is as follows: copper sulfate is the activator, butyl xanthate is the collector Oil is the foaming agent, the amount used in the rough selection is activator 200g / t, collector 120g / t, foaming agent 30g / t, once sweeping: collector 80g / t, foaming agent 10g / t, Secondary sweeping: collector 40g / t, foaming agent 10g / t;

[0053] (3) For the flotation tailings, the cassiterite in it is recovered by using a shaker, roughing, finening, and sweep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com